Catalytic combustion method in combustion chamber of internal combustion engine by curing catalyst

A catalytic combustion and internal combustion engine technology, which is applied in the direction of combustion air/combustion-air treatment, internal combustion piston engine, combustion engine, etc., can solve the problems of increasing vibration and noise, affecting work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

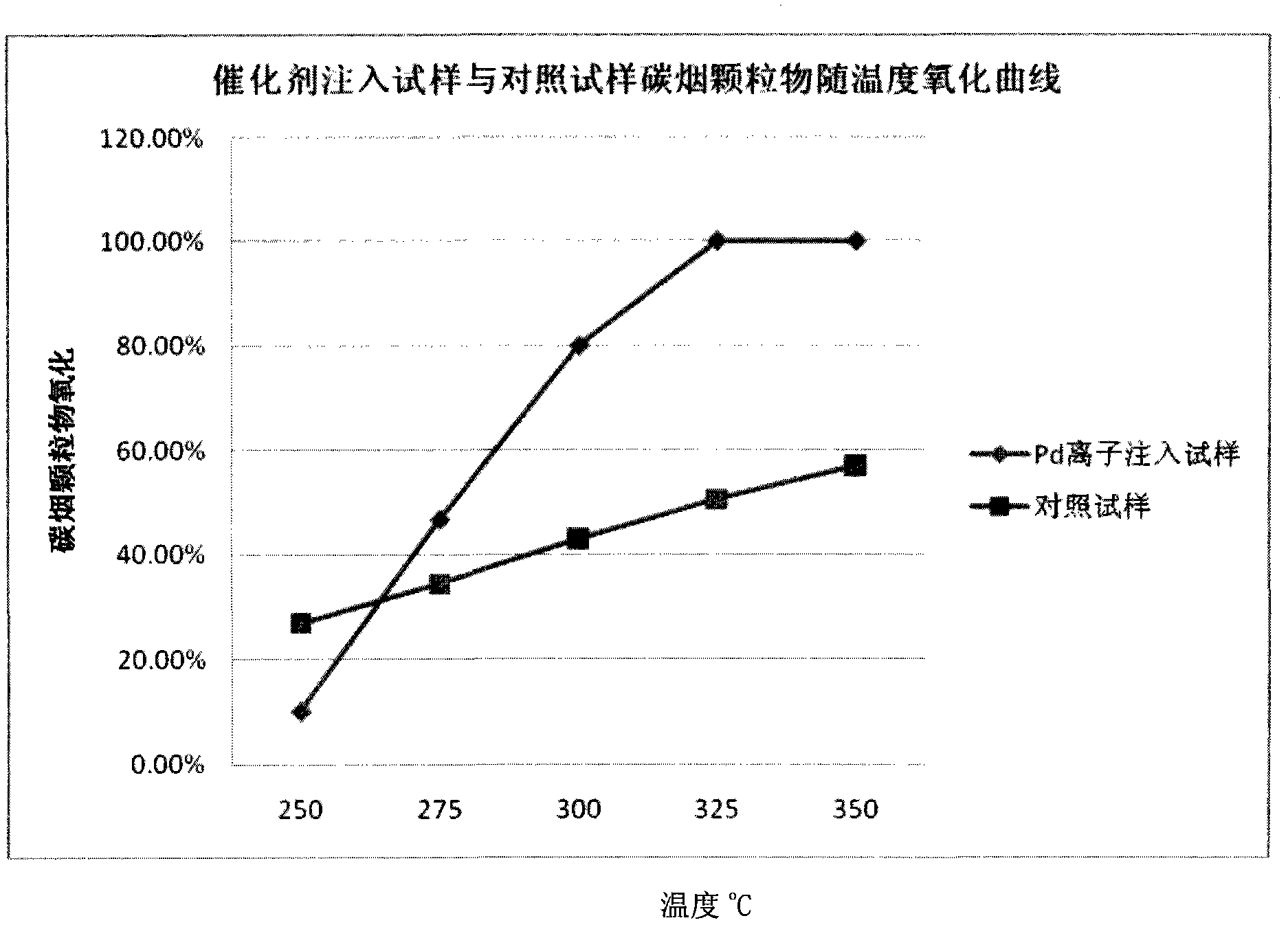

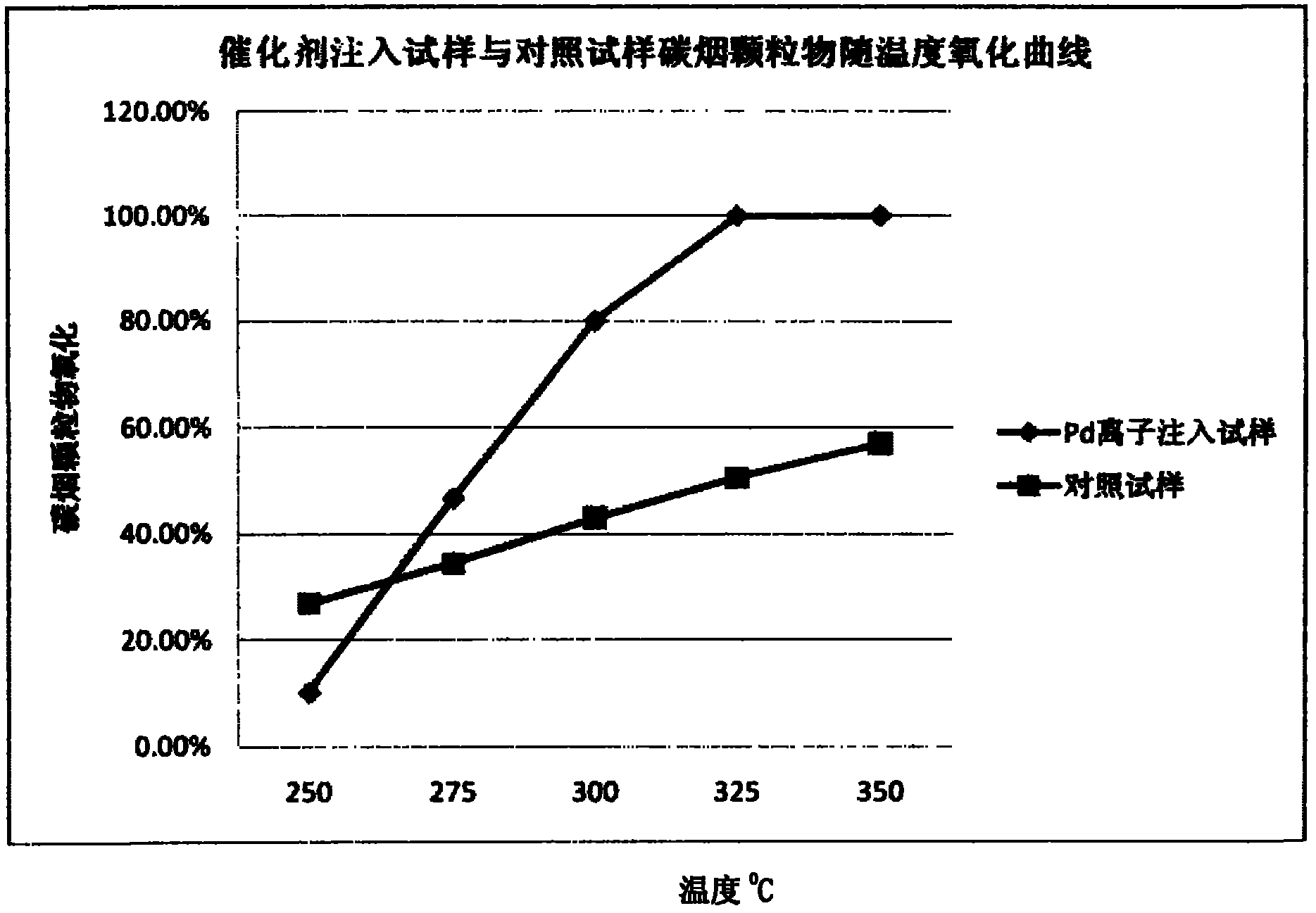

[0016] The catalytic combustion catalyst ion implantation method in the combustion chamber of the internal combustion engine is to use the energy generated by the accelerated electric field and the injection beam during ion implantation. According to the ionization energy of the implanted elements, the binding energy of the ion implanted elements and the elements in the implanted workpiece material, according to the ion implantation range, the ion implantation energy is: 0.1-300KV, and the energy distribution can be selected as continuous Poisson distribution, or high, Medium and low step distribution, the purpose is to promote the high-concentration distribution of the catalyst element combination on the surface of the ion-implanted component, design the high and low changes of the injection voltage based on the conditions, control the size of the implanted ion beam, etc., select various ion implantation conditions to achieve control The energy received by the surface of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com