Automobile fuel control method and controller

A technology of fuel control and controller, which is applied in the field of control of fuel injection volume of cylinder injectors of automobile engines, can solve problems such as complex and inaccurate fuel applicable parameters, and achieve the effect of reducing manual misjudgment and resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

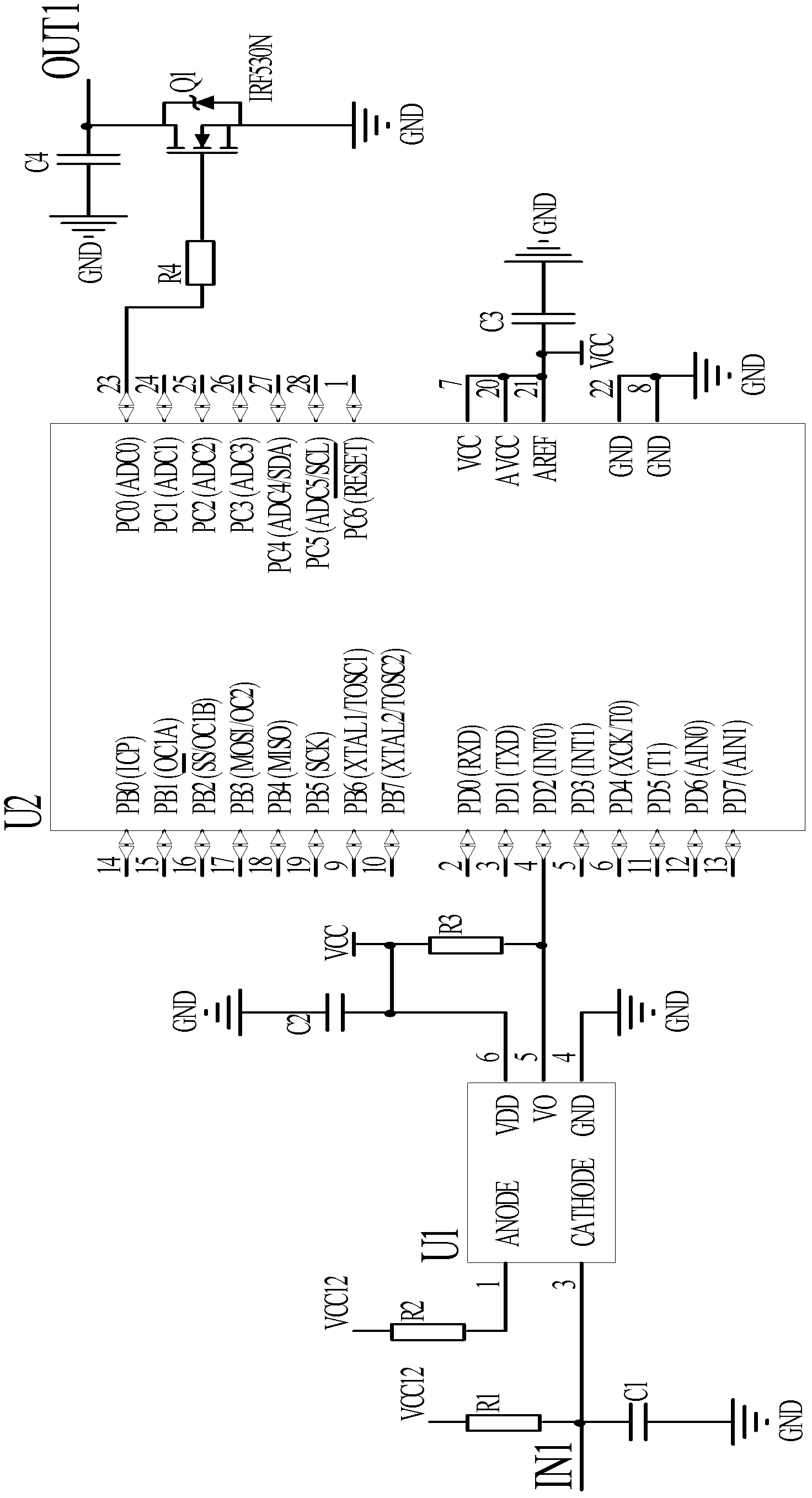

[0030] The controller of this embodiment includes a main control unit, a temperature measuring circuit and a mode switching switch; the main control unit includes a signal input circuit, a shaping circuit, a processing module and a driving circuit connected in sequence, and the mode switching switch is connected to the processing module ; The temperature measurement circuit is connected to the processing module;

[0031] The above signal input circuit includes a resistor R1 and a capacitor C1. One end of the resistor R1 and one end of the capacitor C1 are connected to the car computer in line with each other to obtain the original fuel injection pulse signal output by it. The other end of the resistor R1 is connected to +12V, and the other end of the capacitor C1 is grounded. ;

[0032] The above shaping circuit includes chip U1, resistor R2 and capacitor C2. Chip U1 is a HCPL-M611 photoelectric coupling chip. Pin 1 of chip U1 is connected to one end of resistor R2. Both resis...

Embodiment 2

[0042] The controller in this embodiment is provided with a sub-control unit on the basis of the controller in Embodiment 1, and the components and circuits in the sub-control unit are the same as those in the main control unit, and the sub-control unit The 24 pins and 25 pins of the chip U2 in the main control unit are connected to the 24 pins and 25 pins of the chip U2 in the main control unit, and the 14 pins of the chip U2 in the sub control unit are connected to one end of the external switch for mode switching . Among them, the main control unit and the sub-control unit respectively control the fuel injection quantity of the two cylinder injectors of the automobile engine. The main control unit and the auxiliary control unit perform synchronous control work:

[0043] The main control unit and the sub-control unit receive the mode control switch command;

[0044] When the fuel is gasoline, the chip U2 in the main control unit and the sub-control unit does not do any pro...

Embodiment 3

[0047] The controller in this embodiment is provided with three sub-control units on the basis of the controller in embodiment 1, and the components and circuits in the three sub-control units are all communicated with the components and circuits in the main control unit. The three sub-control units are respectively the first sub-control unit, the second sub-control unit and the third sub-control unit, the pins 24 and 25 of the chip U2 in the first sub-control unit are connected with the pins 24 and 25 of the chip U2 in the main control unit. Pins and 25 pins are connected correspondingly, 24 pins and 25 pins of the chip U2 in the second sub-control unit are connected with 24 pins and 25 pins of the chip U2 in the main control unit, and the chip U2 in the third sub-control unit The 24 pins and 25 pins of the main control unit are connected with the 24 pins and 25 pins of the chip U2 in the main control unit, the 14 pins of the chip U2 in the first sub Pin 14 of U2 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com