Nano fluid channel and manufacturing method thereof

A technology of nanofluid and manufacturing method, which is applied in the manufacture of microstructure devices, decorative arts, gaseous chemical plating, etc., can solve problems such as reducing production cost, and achieve the effect of reducing production cost, smooth sidewall and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

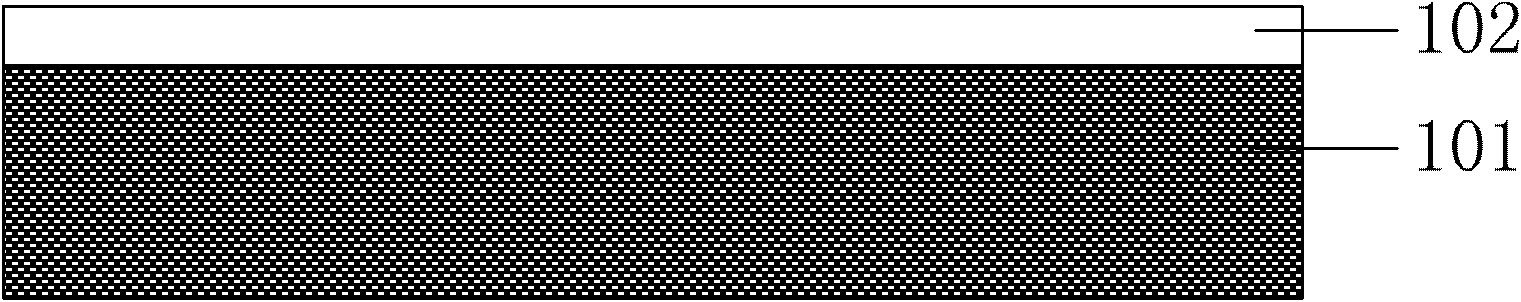

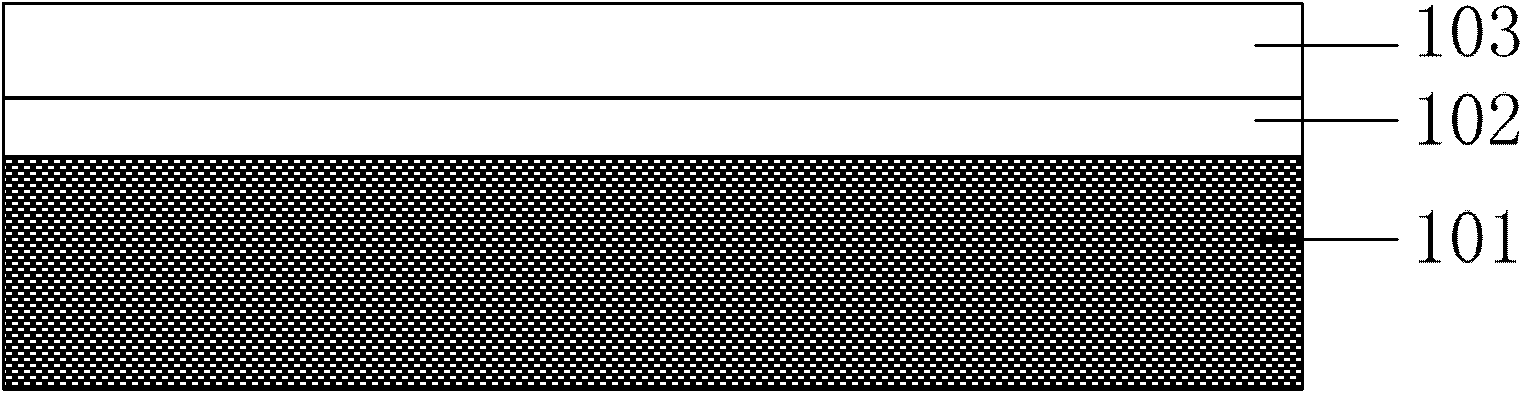

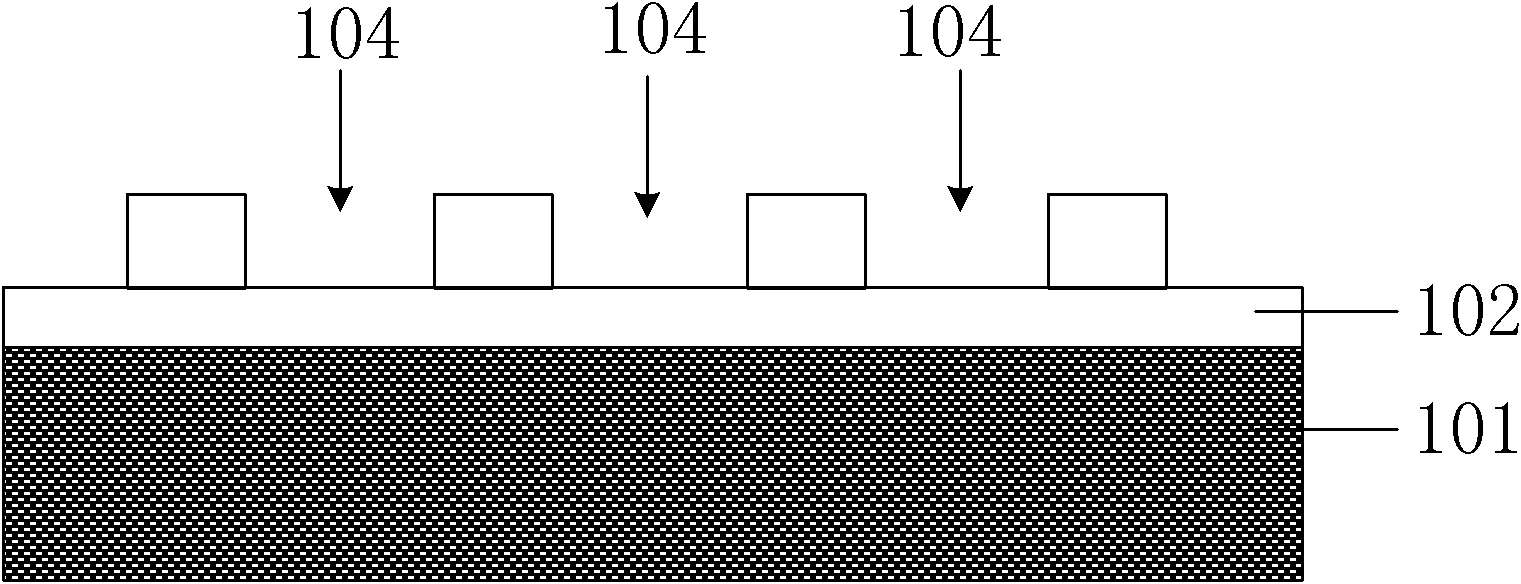

[0015] As mentioned in the background technology, the nanofluidic channel produced by the method in the prior art will have fluid stratification and channel blockage during use, which seriously affects the use of the channel. The inventors have found that the problem occurs The reason is that the side walls of the nanofluid channels made in the prior art are not smooth and not steep, and the lines are uneven, which will undoubtedly seriously affect the normal use of the channels. In order to solve these problems, it is necessary to provide a preparation method for the channels. The side wall of the channel prepared by it is smooth, steep and uniform. That is to say, if the side wall of the channel is to meet the requirements, the premise is that the channel template must meet the above requirements. Continuing this idea, the inventor It is found that the channel templates used in the prior art to fabricate nanofluidic channels have defects such as rough side walls.

[0016] Fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com