Wire discharging frame

A pay-off frame and body part technology, applied in the field of pay-off racks, can solve problems such as messy threads, increased production costs, and different normal production, and achieve the effect of ensuring pay-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

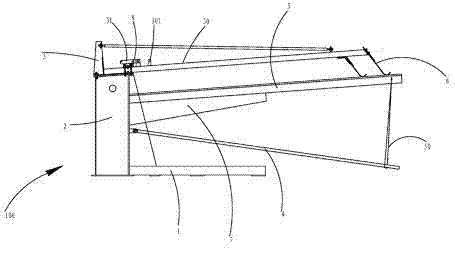

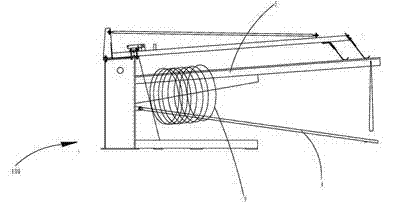

[0009] see figure 1 and figure 2 , a pay-off stand 100, the pay-off stand 100 includes a machine base 1, a body part 2 protruding from the machine base 1, a rotating part 3 and a screw rod 4 installed on the main body part 2, the rotating part 3 And the screw rod 4 can rotate relative to the body part 2, the body part 2 protrudes with a hanging rod 5 integrally formed with the body part 2, the rotating part 3 is arranged in a triangle and is provided with a mounting rod 30, the Two shrapnels 6 are installed on the front end of the mounting rod 30 . The elastic piece 6 is mounted on the front end of the mounting rod 30 through a fixing member. A supporting rib 7 is provided between the hanging rod 5 and the main body 2 , so as to enhance the structural strength between the hanging rod 5 and the main body 2 . A chain 50 is installed on the hanging rod 5, and when the steel wire rod 9 needs to be loaded on the pay-off frame 100, the chain 50 is encased on the screw rod 4, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com