Deadbeat wire-drawing production equipment

A production equipment, straight-forward technology, applied in the field of straight-forward wire drawing production equipment, to achieve the effects of reducing consumption, smooth pay-off, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

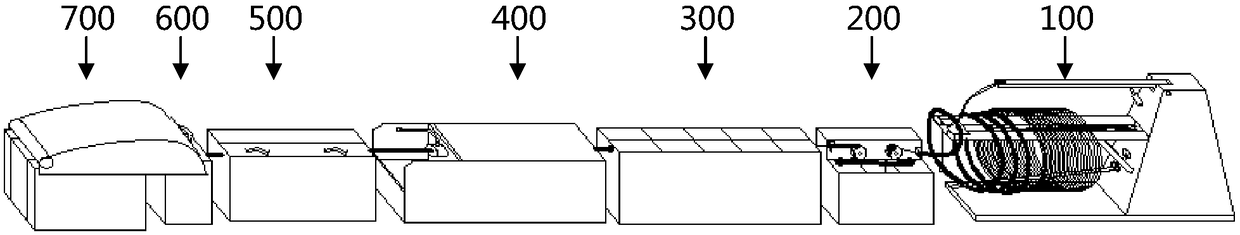

[0050] Such as Figure 1 to Figure 6 As shown, a kind of in-line drawing production equipment of the present embodiment comprises a wire rod pay-off device 100, a sheller 200, a borax coating device 300, a borax collecting device 400, a dryer 500, a cold drawing machine 600 and Wire drawing coiler 700, wire rod pay-off device 100, sheller 200, borax coating device 300, borax collecting device 400, dryer 500, cold drawing machine 600 and wire drawing coiler 700 in sequence along the wire drawing direction.

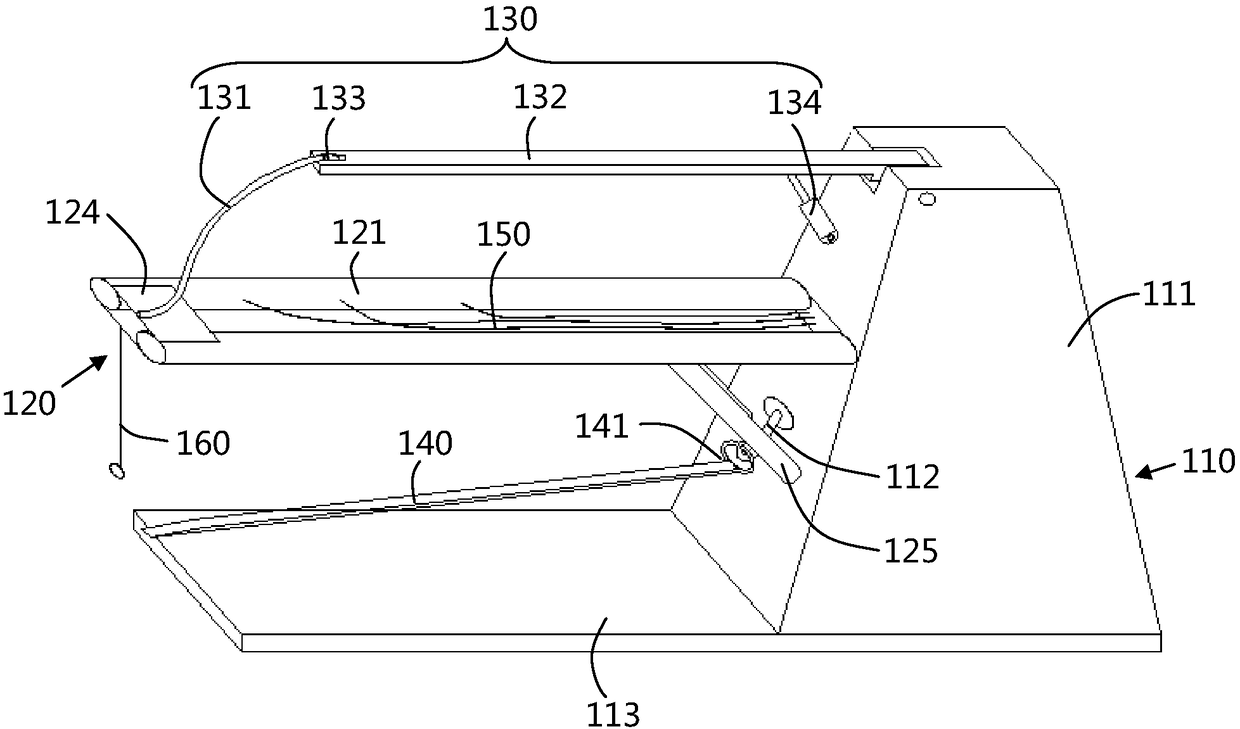

[0051] In this embodiment, the wire rod pay-off device 100 includes a base 110 , a carrying mechanism 120 , a crimping mechanism 130 and an anti-jump board 140 .

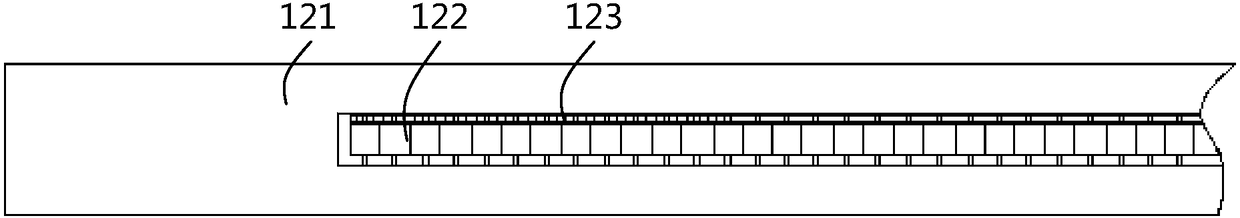

[0052] The supporting mechanism 120 has two supporting rods 121 arranged in parallel, and a shelving plate 124 is arranged at the head of the two supporting rods 121 , and the two supporting rods 121 are horizontally fixed on the base 110 .

[0053] Further, the thread-pressing mechanism 130 has a thread-pressin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com