Pay-off rack of doubling machine

A pay-off frame and doubling machine technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the mismatch between pay-off speed and doubling speed, affect doubling quality, and yarn breakage and other problems, to achieve the effect of improving stability and smoothness, ensuring the quality of merging, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is attached Figure 1-5 The present invention is described in further detail.

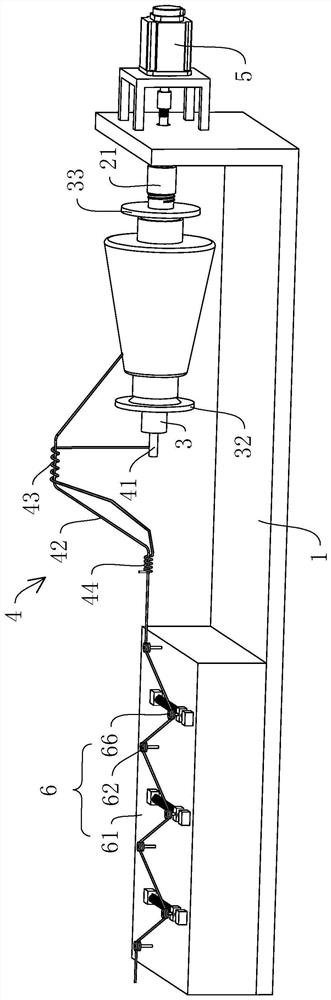

[0035] The embodiment of the present application discloses a pay-off frame of a doubling machine. refer to figure 1 and figure 2 , The doubling machine pay-off frame includes a base 1, an installation shaft 2 arranged on the base 1, a bobbin fixed shaft 3 fixed on the installation shaft 2, and a wire guide 4 rotatably arranged on the bobbin fixed shaft 3. The bobbin can be fixed on the bobbin fixing shaft 3 . The yarn on the bobbin passes through the thread guide 4, and the yarn is pulled, and the thread guide 4 can perform a revolving movement around the fixed shaft 3 of the bobbin, and at the same time, the thread guide 4 stirs the yarn to make the yarn fall off from the bobbin, that is, Yarn pay-off can be completed.

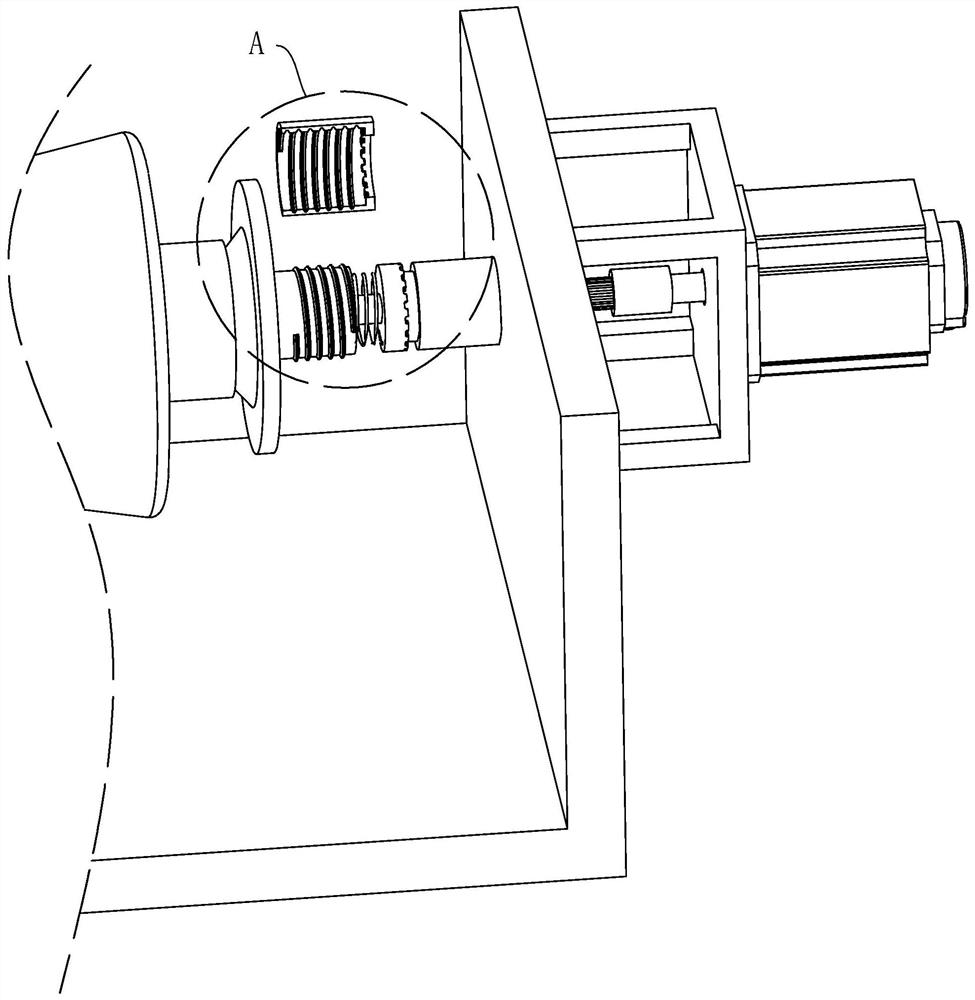

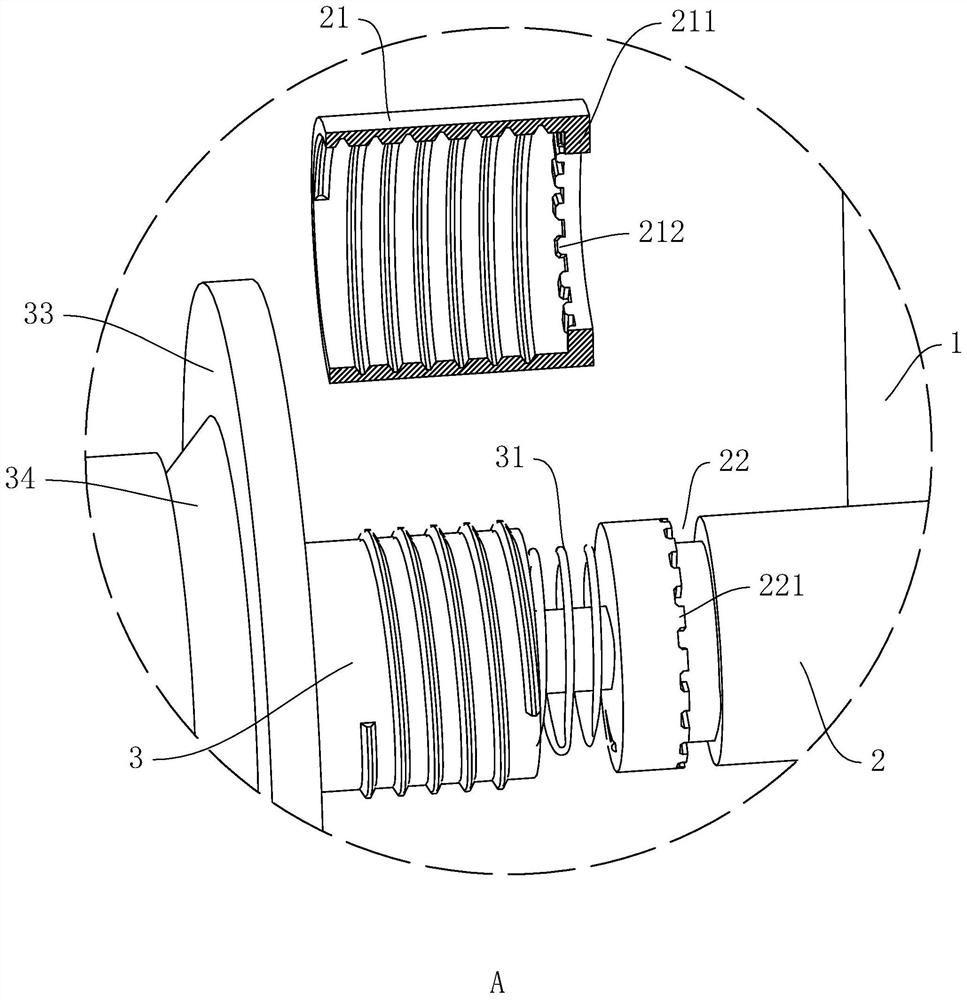

[0036] refer to figure 2 and image 3 , the installation shaft 2 is provided with a fixed collar 21, one end of the fixed collar 21 extends to the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com