Packaging-integrated nuclear track anti-counterfeiting disk and manufacturing method thereof

A manufacturing method and nuclear track technology, applied in the packaging integrated nuclear track anti-counterfeiting tape and its manufacturing field, can solve the problems of complex process, high production cost, and inability to realize the integration of anti-counterfeiting materials and target object packaging, etc. To achieve the effect of expanding the application field and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

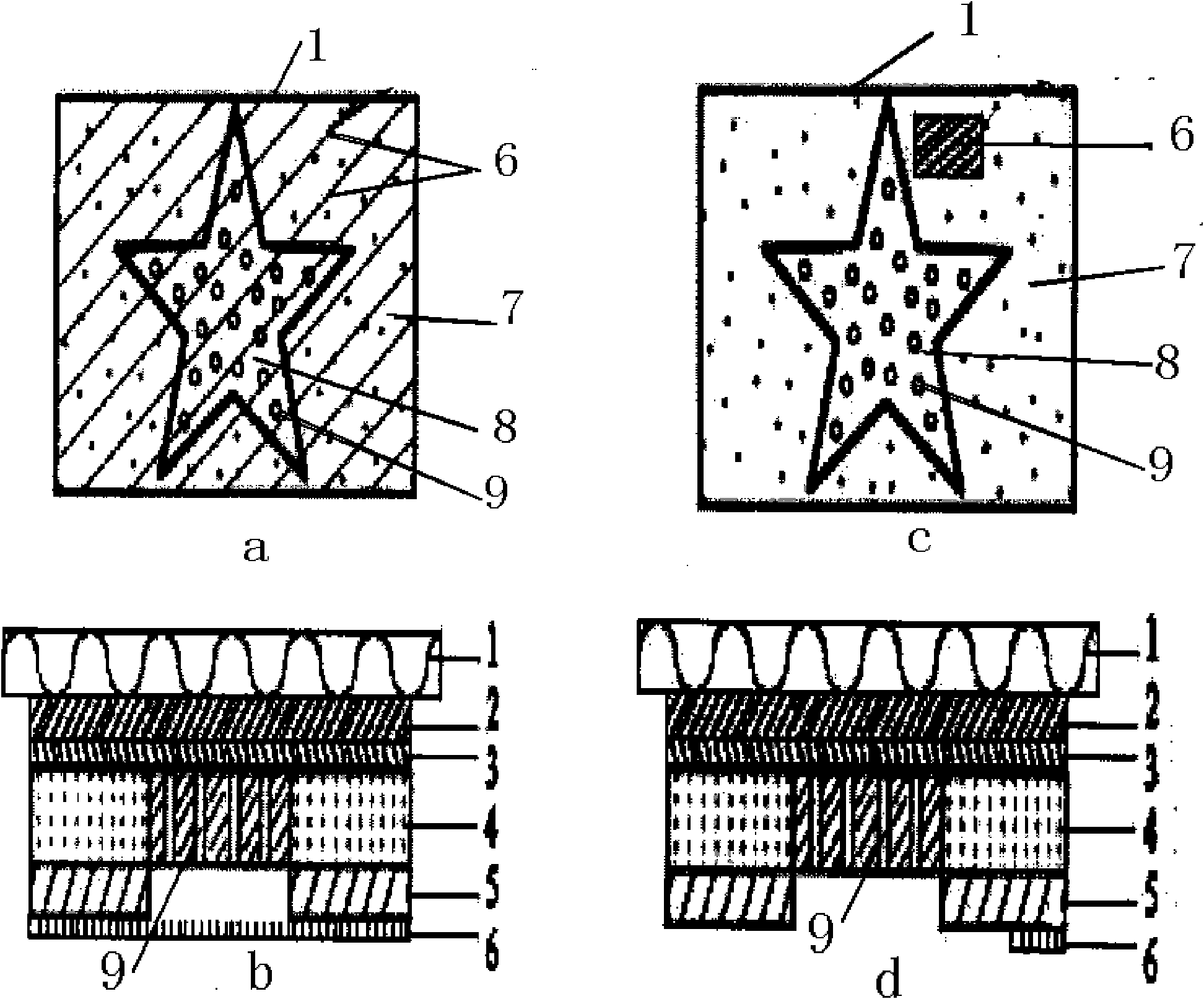

[0024] Laser nuclear track anti-counterfeiting thermal transfer film dribbling:

[0025] 1) Irradiate a 15 μm thick PET film with reactor fission fragments;

[0026] 2) On the irradiated PET film, make a printing plate according to the required pattern;

[0027] 3) Print the adhesive layer 2 (hot melt) on the PET film with a gravure printing machine;

[0028] 4) Print an acrylic release layer 3 on a PET film with an irradiated latent track, wherein the printing thickness is 0.8g / m 2 ;

[0029] 5) Coat 5.0g / m on the release layer 2 Water-soluble pressure-sensitive adhesive (self-adhesive), then compounded with another PET film with an adhesive layer 2 to form a composite film;

[0030] 6) Chemical etching: use 8N NaOH at 80°C to chemically etch the above composite film for 15 minutes, so that the radiation damage in the area without a protective layer is enlarged from a few nanometers to a few micrometers, and it is composed of a large number of micrometer-scale micropores....

Embodiment 2

[0038] Partial laser nuclear track anti-counterfeiting thermal transfer film dribbling

[0039] 1) Accelerator-accelerated 10MeV / u Ar-40 irradiates 50μPVDF polyvinylidene fluoride film;

[0040] 2) Make a printing plate according to the required pattern;

[0041] 3) Gravure printing hot melt on PVDF;

[0042] 4) Print an acrylate release layer on the irradiated PVDF polyvinylidene fluoride, the printing thickness is 1g / m 2 ;

[0043] 5) Coat 8.0g / m on the release layer 2 Water-soluble pressure-sensitive adhesive (self-adhesive), and then compounded with printed hot-melt PVDF film to form a composite film;

[0044] 6) Chemical etching: 8N NaOH at 80°C, chemically etch the above composite film for 12 minutes, so that the radiation damage in the area without a protective layer is enlarged from a few nanometers to a few micrometers, and it is composed of a large number of micrometer-sized pores that are visible to the naked eye The pattern area 8 of the non-pattern area 7 is ...

Embodiment 3

[0052] Partial laser nuclear track anti-counterfeiting thermal transfer film dribbling:

[0053] 1) Accelerator-accelerated 20MeV / u Kr-84 irradiates 50μBET polyester film;

[0054] 2) Make a printing plate according to the required pattern;

[0055] 3) Gravure printing hot melt on 20μ PETT, printing thickness 1g / m 2 ;

[0056] 4) Print the acrylate release layer on the irradiated BET, the printing thickness is 1g / m 2 ;

[0057] 5) Coat 3.0g / m on the release layer 2 Water-soluble pressure-sensitive adhesive (self-adhesive); then compounded with PETT film of printed hot-melt to form a composite film;

[0058]6) Chemical etching: 8N NaOH at 80°C, chemically etch the above composite film for 20 minutes, so that the radiation damage in the area without a protective layer is enlarged from a few nanometers to a few micrometers, and it is composed of a large number of micrometer-sized pores that are visible to the naked eye The pattern area 8 of the non-pattern area 7 is coated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com