Block turning machine for mechanical processing of graphite product

A technology of mechanical processing and graphite products, applied in the direction of stone processing equipment, manufacturing tools, work accessories, etc., can solve the problems of safety, hidden dangers, and low efficiency of graphite blocks for workers and products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

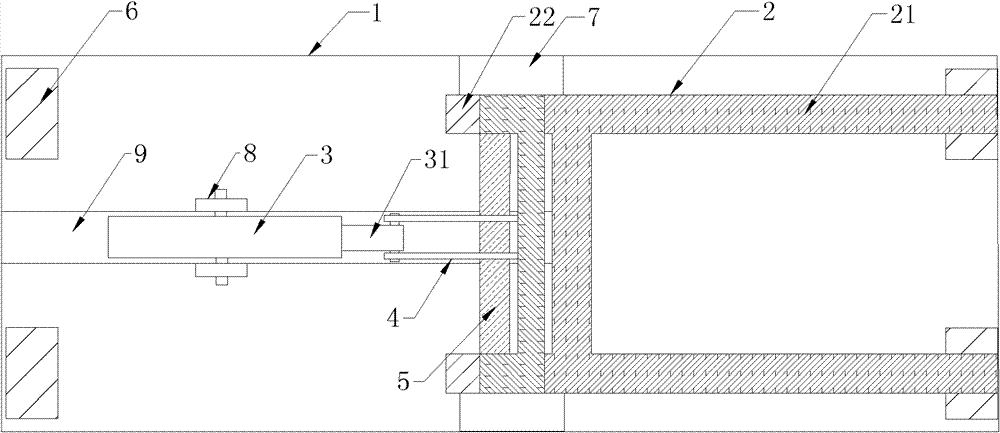

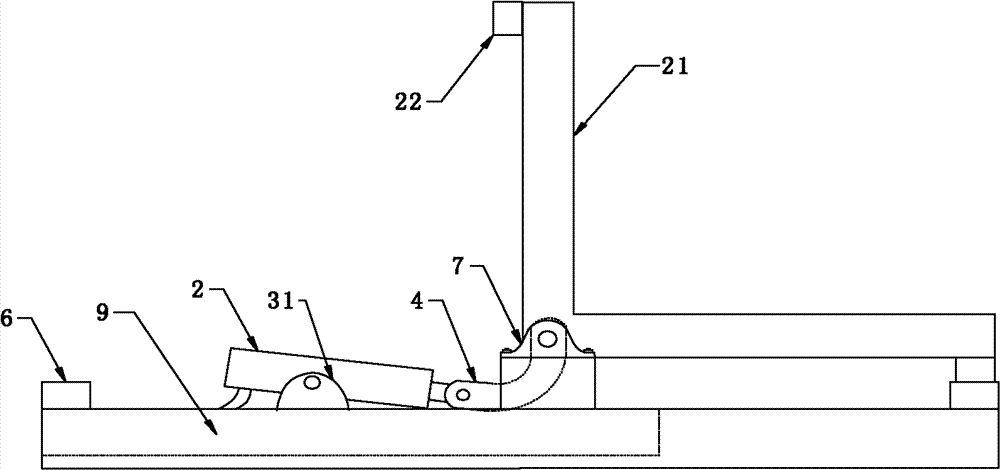

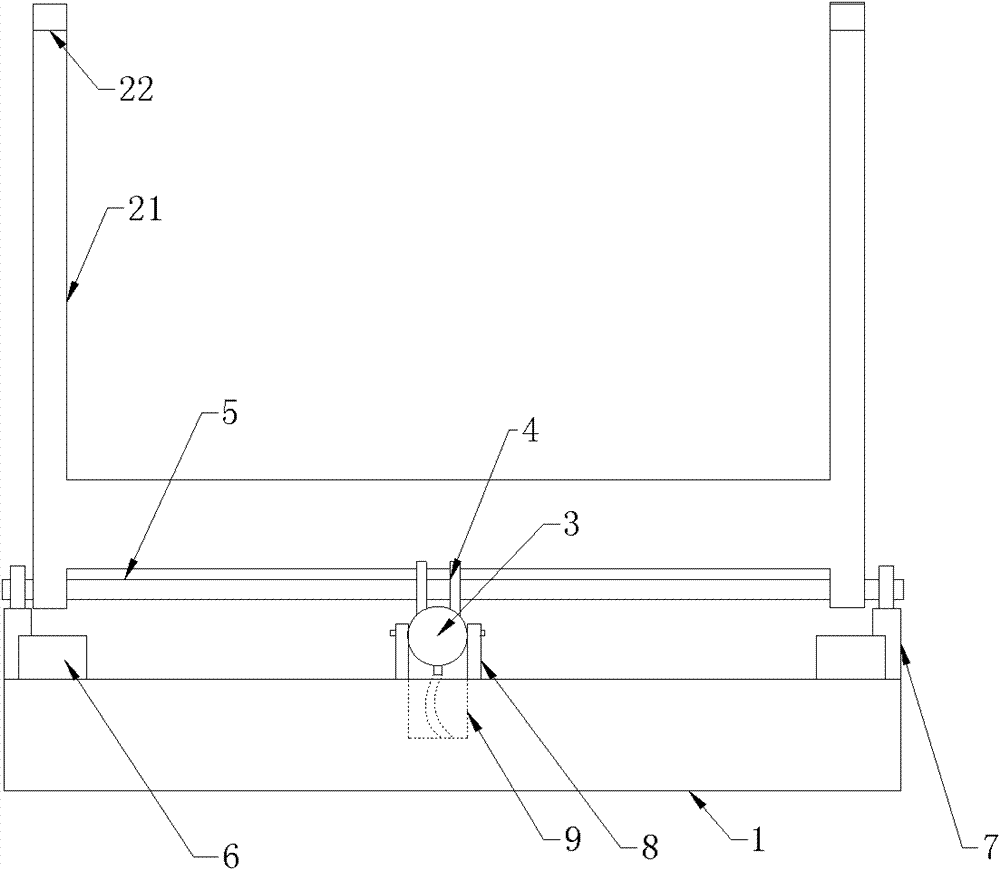

[0021] Such as figure 1 As shown, this scheme includes a base frame on which a flip frame and a hydraulic cylinder are installed, the hydraulic cylinder is fixed on the base frame, the piston rod of the hydraulic cylinder is connected to the flip frame, and the flip frame adopts two U-shaped frames It is welded. The ends of the two U-shaped frames with the top edge are perpendicular to each other. A rotating shaft is fixed on the right-angled side of the flip frame, and a bearing seat is respectively fixed on the axial side of the base frame. The two ends of the rotating shaft are respectively The installation direction of the hydraulic cylinder is perpendicular to the rotation axis and is located in the center of the rotation axis. An elbow is fixed at the center of the rotation axis. The angle of the elbow is 80-100 degrees, preferably 90 degrees. , the opening direction of the elbow is opposite to the opening direction of the turning frame, one end of the elbow is fixed on ...

Embodiment 2

[0024] On the basis of the above examples, if figure 1 , 2 , 3, in this scheme, a groove perpendicular to the rotation axis is provided on the base frame, and the hydraulic cylinder is fixed in the groove by using the fixing seats on both sides of the groove, and there is an included angle between the hydraulic cylinder and the base frame , that is, one end of the hydraulic rod of the hydraulic cylinder is inclined downward, and the angle of inclination of the hydraulic cylinder is related to the angle between the elbow and the rotation axis, which is generally less than 90 degrees. This solution can reduce the distance between the base frame and the overturn frame, and at the same time can push the rotation shaft to rotate through the elbow with less thrust, because the thrust direction is the arc tangent direction centered on the rotation shaft.

Embodiment 3

[0026] On the basis of the above examples, if figure 1 , 2 , Shown in 3, this program is at the termination of one side of U-shaped frame and base contact, support block is set, cushion pad is set on the place corresponding to support block on the base frame. This can avoid direct contact between the U-shaped frame and the base frame, and prevent the twisting deformation caused by hard collision between the U-shaped frame and the base frame during the rotation of the overturning frame. The buffer pad can be made of flexible materials, such as rubber, wood, plastics, etc., or be lined with wood as a combination of modes such as rubber on the bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com