Magnetic coupler and gap tank for magnetic coupler

A magnetic coupler and gap technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, electromechanical device, etc., can solve the problems of uneconomical and expensive manufacturing, and achieve the effect of no eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

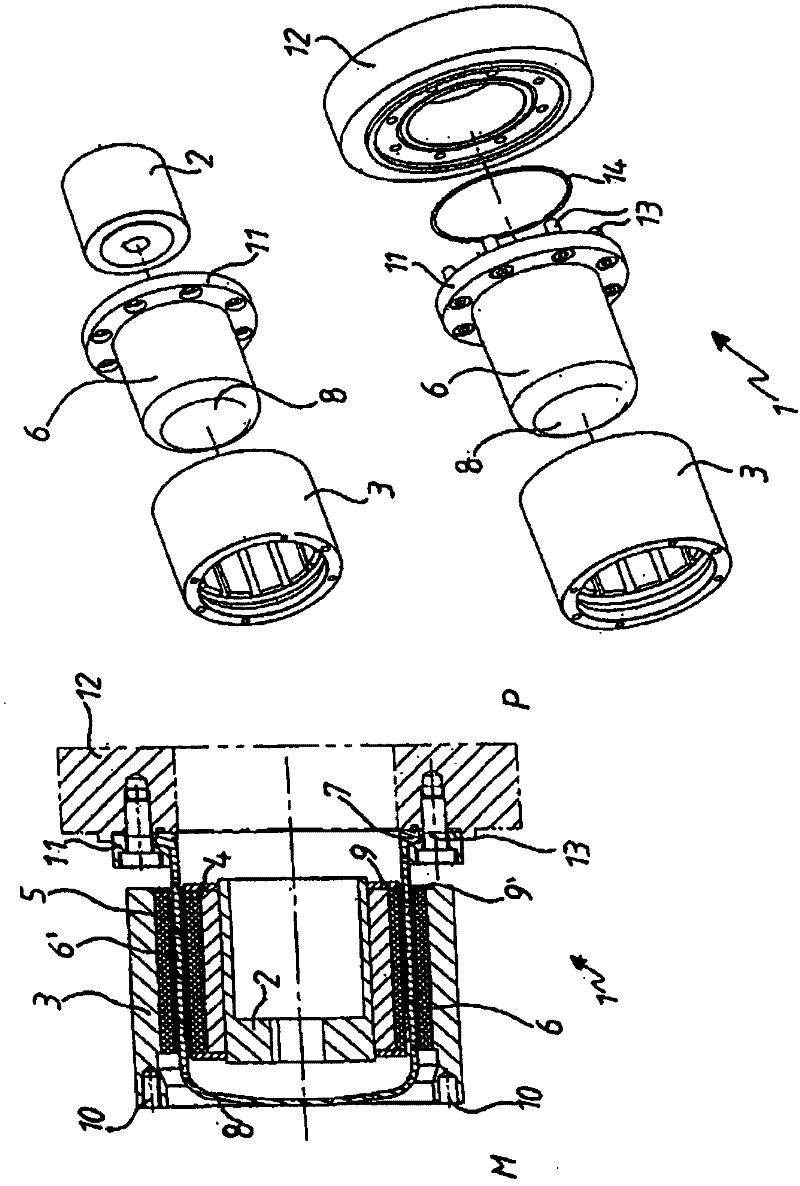

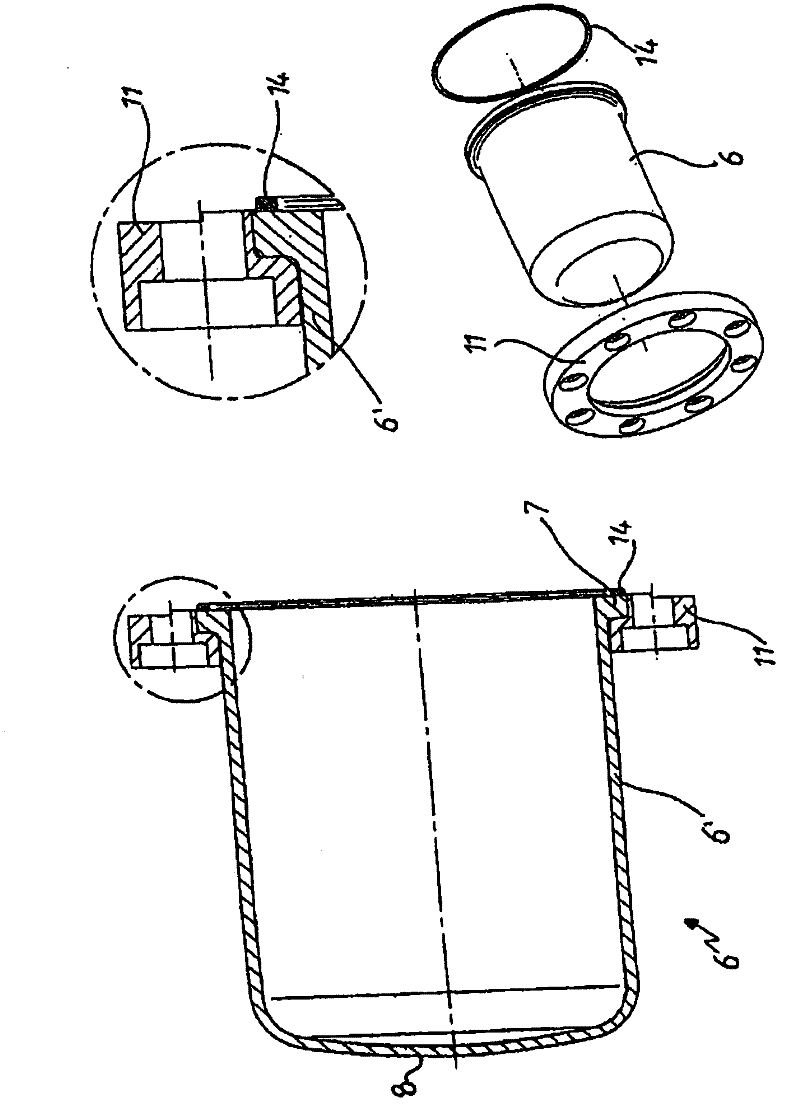

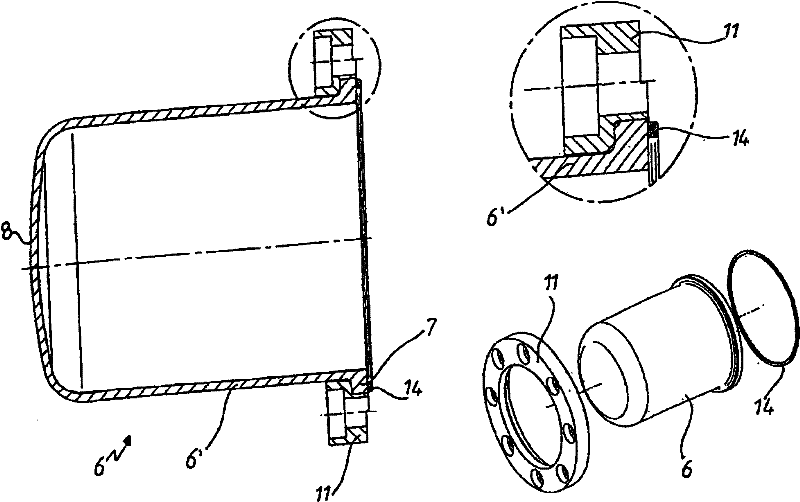

[0028] figure 1 A perspective view showing the structure of the magnetic coupler 1 of the invention on the one hand, and a partially assembled state of the magnetic coupler 1 on the other hand. The magnetic coupler 1 includes the following main components:

[0029] An inner rotor 2 , an outer rotor 3 , both equipped with corresponding magnets 4 , 5 , and a slotted pot 6 . The slot tank 6 has a flange 7 and a closed bottom 8 . The tubular section 6 ′ extending between the base 8 and the flange 7 is here positioned in the air gap 9 , 9 ′ between the magnets 4 , 5 with a minimum gap (+ / - 0.1 mm). According to the invention, the slot tank 6 is made of borosilicate glass, which is particularly resistant to chemical materials and pressure, temperature fluctuations and has a size of less than 4×10 -6 / K coefficient of thermal expansion. When installed, the motor side M and the pump side P are exposed. On the motor side, threaded holes 10 are introduced in the outer rotor, on whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com