Energy-saving high-voltage DC traction power supply converter device and control method without AC inductance

A high-voltage direct current, traction power supply technology, applied in the conversion of AC power input to DC power output, irreversible AC power input into DC power output, output power conversion device, etc., can solve the problem of resistance consumption and catenary network voltage drop Large, energy can only flow in one direction, etc., to achieve the effect of increasing the DC output voltage, reducing the catenary loss, and keeping the total output voltage constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

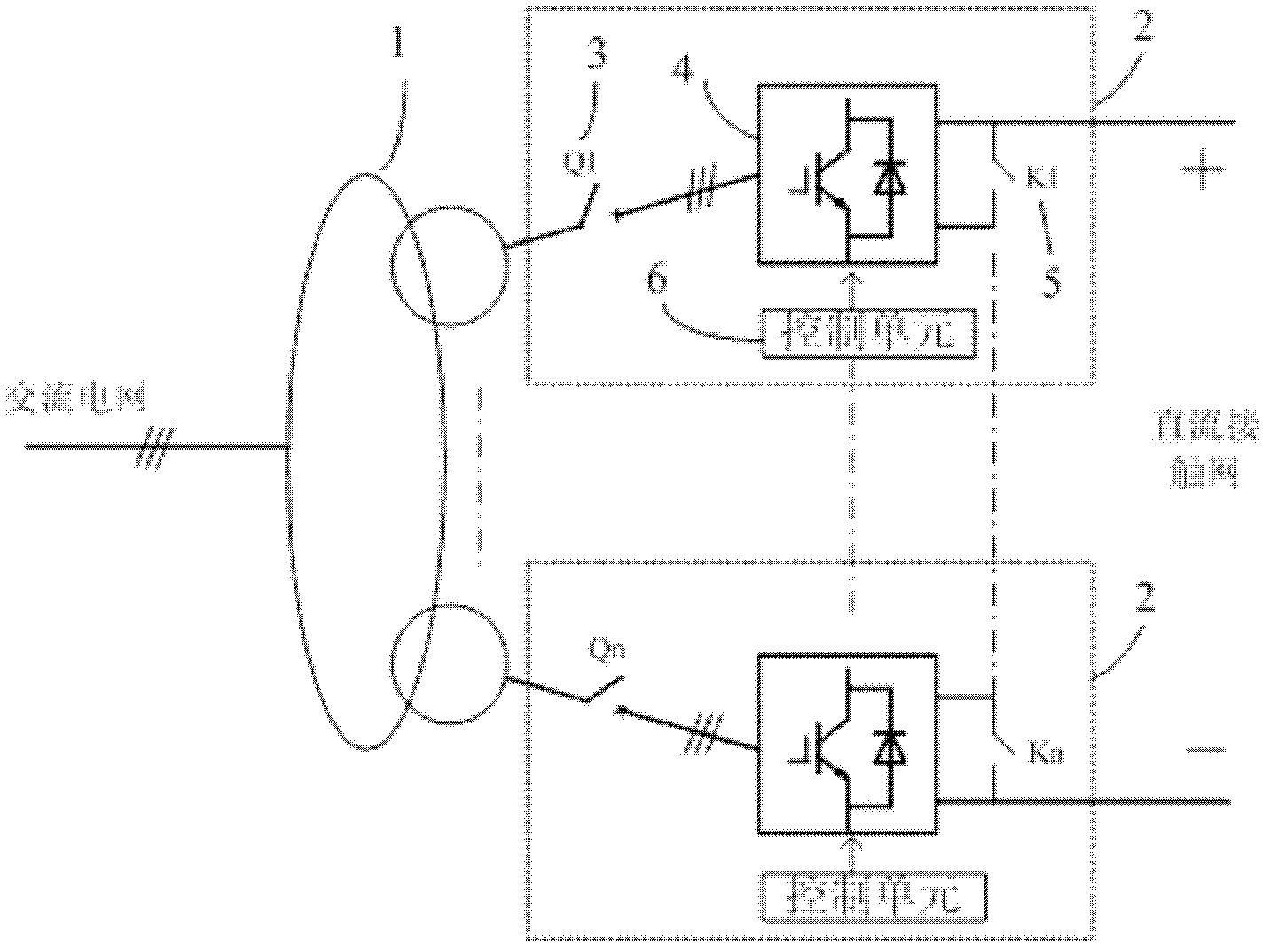

[0030] Example: such as image 3 , Figure 4 As shown, the multi-winding transformer 1 adopts epoxy resin casting dry-type transformer, which has one primary winding and three secondary windings. The connection mode of the multi-winding transformer 1 adopts Yd1, d1, and the transformation ratio of d1 is 35kv / 1.8kv / 1.8kv / 1.8kv, the capacity is 9MVA, and the equivalent short-circuit impedance of the secondary winding is 20%. Corresponding to the number of multi-winding transformers, there are three PWM rectifier units 4, the AC side of each PWM rectifier unit 4 is respectively connected to a secondary winding of the multi-winding transformer 1, and the DC side is connected in series in sequence. The DC output rated voltage of each PWM rectifier unit 4 is 3kV, and the capacity is 3MW.

[0031] In order to reduce the withstand voltage of the power devices in each PWM rectifier unit 4 and increase the system capacity at the same time, the main circuit of each PWM rectifier unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com