Anti-counterfeiting mark structure and manufacturing method thereof

A technology of anti-counterfeiting marks and manufacturing methods, which is applied in the field of anti-counterfeiting printing and digital anti-counterfeiting, and can solve problems such as label recycling and transfer fraud, failure to achieve multiple anti-counterfeiting functions, and weakening of the variable barcode on the surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

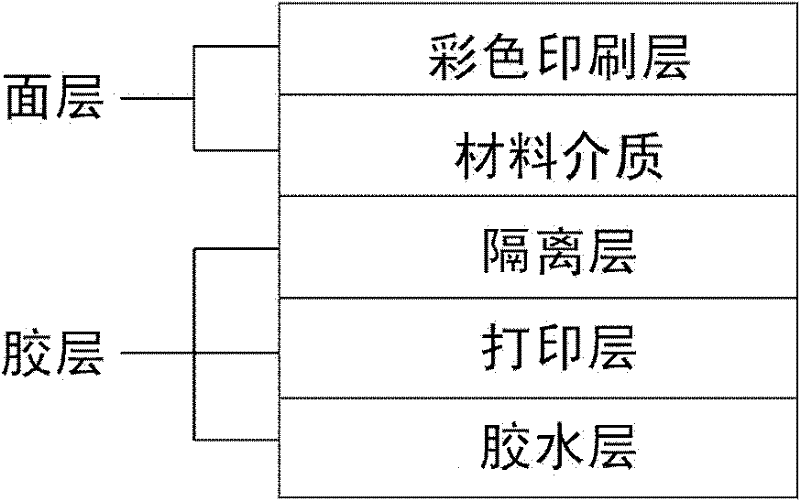

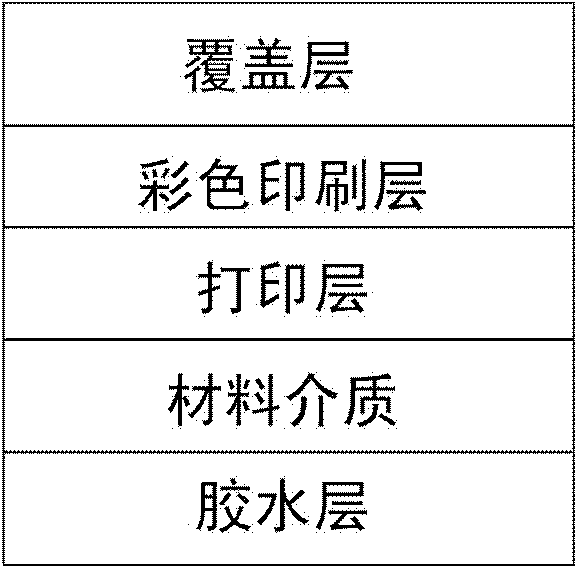

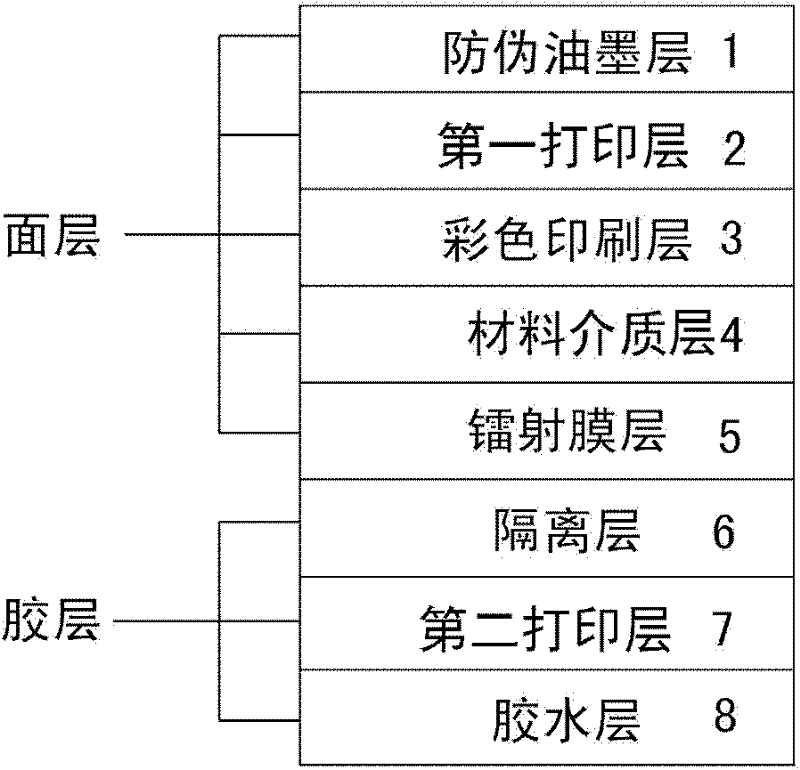

[0079] see Figure 3 to Figure 6 As shown, the anti-counterfeiting mark structure includes a surface layer structure and a glue layer structure attached to the lower surface of the surface layer structure, wherein the surface layer structure includes:

[0080] Material medium layer 4; the material medium layer 4 can be PET film, coated paper or synthetic paper;

[0081] The printing layer 3 covers the upper surface of the material medium layer 4 and is used to carry the base pattern information of the printed anti-counterfeiting label; in a specific embodiment of the present invention, the printing layer 3 is a color ink printing layer, and the base The pattern information can be a color pattern and / or a logo, etc.;

[0082] The first printing layer 2 covers a specified position on the upper surface of the printing layer 3, and is used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com