Monte Carlo Simulation Method of Batch-feeding Process Conditions in Copolymerization

A technology of Monte Carlo simulation and process conditions, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as uneven distribution of chain segments and content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

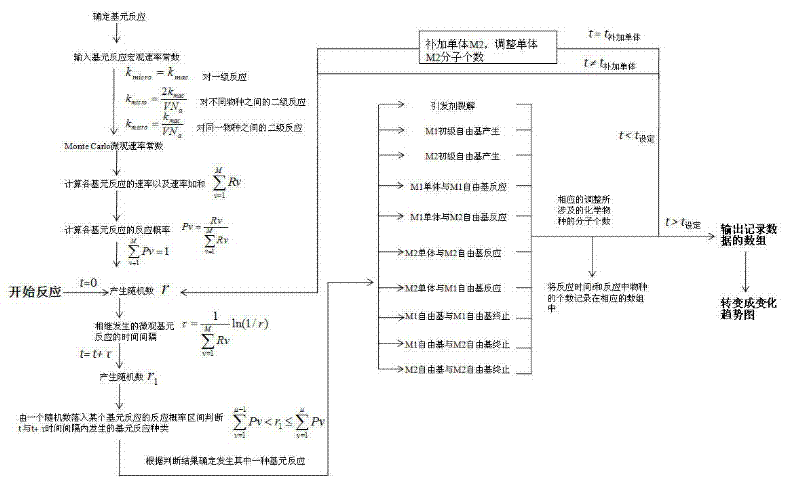

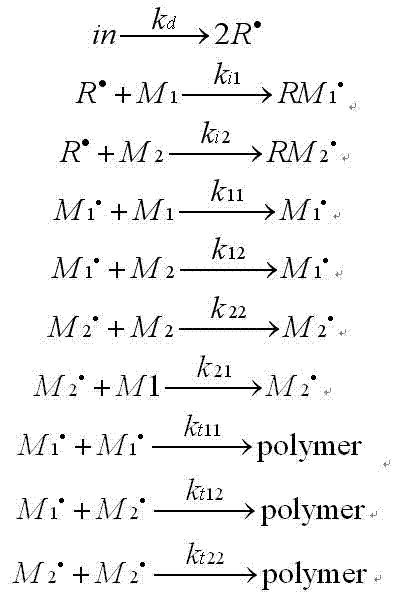

Method used

Image

Examples

Embodiment 1

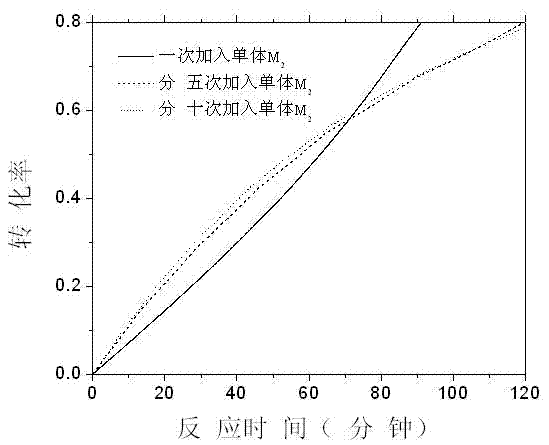

[0051] Example 1 The present invention is further described through this example, in this example monomer M 2 For the copolymerization reaction system that is added in six batches, the addition time and the addition amount are respectively: 0 minutes, add M 2 42% of the total; add M in 21 minutes 2 18% of the total; add M in 42 minutes 2 14% of the total; 63 minutes to add M 2 10% of the total; 84 minutes to add M 2 10% of the total; add M in 105 minutes 2 6% of the total. .The molar ratio of the monomer and the initiator in the system is 200:1, the monomer M 1 with monomer M 2 The molar ratio is 98.75:1.25, and the elementary reaction that the described system includes is: the decomposition reaction of AIBN, decomposition rate constant K d 1.7×10 -5 the s -1 ,M 1 Free radicals and monomer M 1 growth response, growth rate constant K 11 5×10 4 L·mol -1 ·s -1 ; 1 Free radicals and monomer M 2 The growth response, the growth rate constant K 12 2×10 5 L·mol...

Embodiment 2

[0057] Example 2 The present invention is further described through this example, in this example monomer M 2 For the copolymerization reaction system that was added in ten batches, the addition time and the addition amount were respectively, and M was added in 0 minutes 2 36% of the total; add M in 10 minutes 2 9% of the total; add M in 20 minutes 2 8% of the total; add M in 30 minutes 2 8% of the total; add M in 41 minutes 2 8% of the total; 52 minutes to add M 2 6% of the total, add M at 63 minutes 2 6% of the total; 74 minutes to add M 2 4% of the total; add M in 85 minutes 2 4% of the total; 103 minutes to add M 2 4% of the total. The molar ratio of monomer and initiator in the system is 200:1, monomer M 1 with monomer M 2 The molar ratio of is 98.75:1.25, and the elementary reaction that the described system includes is: the decomposition reaction of initiator AIBN, decomposition rate constant K d 1.7×10 -5 the s -1 ,M 1 Free radicals and monomer M 1 grow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com