A masonry method for rh refining furnace that can reduce refractory consumption

A refining furnace and refractory technology, which is applied in the field of RH refining furnace masonry, can solve the problem of increased time and labor intensity for repairing masonry, achieve rapid repair and replacement of dipping pipes, reduce the number of abnormal offlines, and optimize the removal process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through embodiment.

[0017] In an embodiment, the specific process steps are as follows:

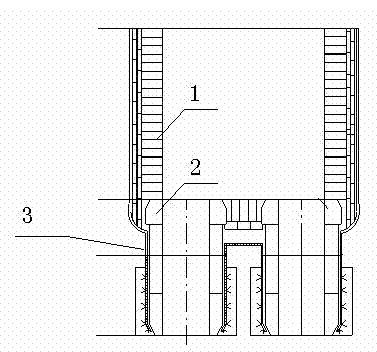

[0018] ① Staggered joint masonry: In the process of vacuum tank masonry, the refractory bricks are built with staggered joints, which can not only increase the firmness and corrosion resistance of the refractory material in the working layer of the vacuum tank, but also provide excavation when replacing the dipping tube. The repair method saves refractory materials and lays the structural foundation;

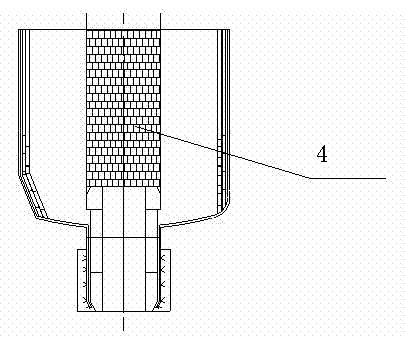

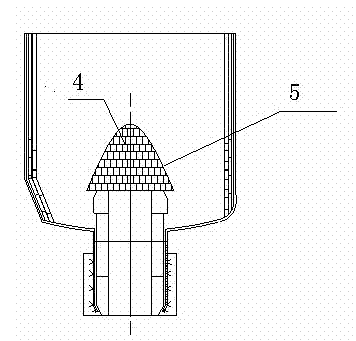

[0019] ②Pyramid excavation and repair: After the impregnation pipe reaches the service life, the vacuum tank will be taken off the line to replace the impregnation pipe; The groove bricks at the top of the groove are all removed and replaced with new groove bricks (such as image 3 As shown), it can be seen that not only a large number of groove bricks that have not reached their service life are wasted, but also the labor loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com