Ti-zr-cu-ni(fe)-be alloy with extremely high amorphous forming ability and preparation method

A ti-zr-cu-ni, amorphous alloy technology, applied in the field of Ti-Zr-Cu-Ni-Be alloy and preparation, can solve the problem of not meeting the needs of practical applications, achieve broad industrial application prospects, reduce Cost, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

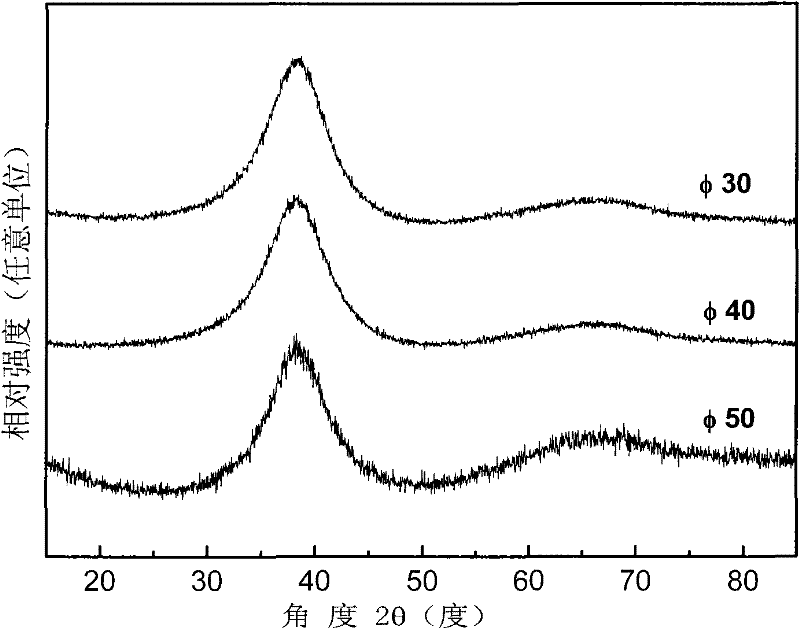

[0028] [Ti a Zr b (Ni x Fe 1-x ) c be d ] 100-y Cu y In the alloy system, a=36%; b=33%; c=6%; d=25%; x=1; y=9 (denoted as ZT3, atomic percentage). The Ti and Zr in the raw materials are sponge Ti and sponge Zr with industrial purity, and the purity of other elements is higher than 99.8wt%. After a certain quality of raw materials is prepared according to the atomic percentage, the master alloy is prepared by arc melting under the protection of argon. Ingots, in order to ensure the uniformity of the smelted alloy ingots, the alloy ingots were repeatedly smelted four times. The present invention adopts water quenching casting, and the degree of vacuum is 8×10 -4 Pa, at a temperature of 1000°C, through water quenching equipment, to obtain an amorphous rod with a size of Φ50×65mm. figure 1 It is the X-ray diffraction spectrum of water-quenched ZT3 alloys with different sizes. It can be seen from the figure that the diffraction curves of ZT3 alloys with diameters of 30mm, ...

Embodiment 2

[0032] Different from Example 1,

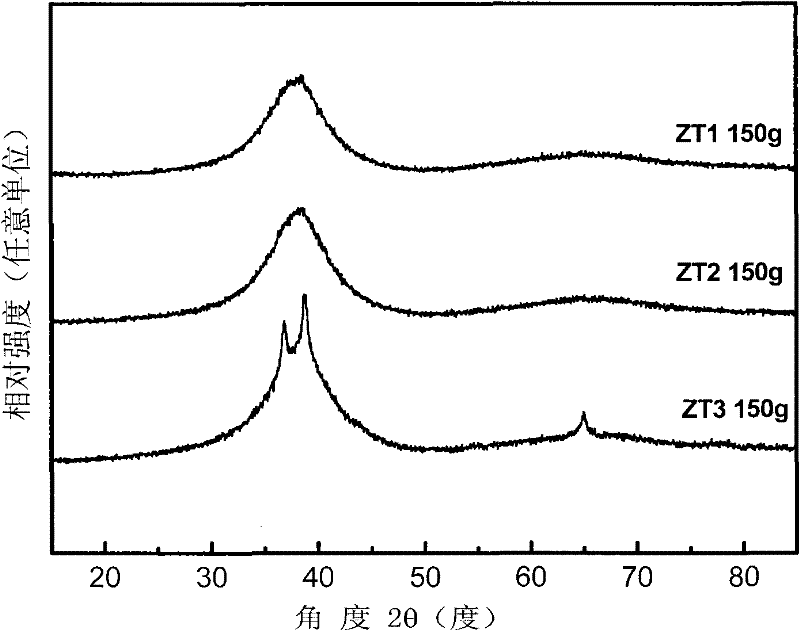

[0033] [Ti a Zr b (Ni x Fe 1-x ) c be d ] 100-y Cu y In the alloy system, a=36%; b=33%; c=6%; d=25%; x=1; y=5 (denoted as ZT1, atomic percentage). The ZT1 master alloy ingot with a mass of 150g has a single amorphous structure, such as figure 2 shown.

[0034] Thermodynamic characteristics: glass transition temperature is 600K; initial crystallization temperature is 645K; liquidus temperature is 995K; supercooled liquid phase width is 45K.

Embodiment 3

[0036] Different from Example 1,

[0037] [Ti a Zr b (Ni x Fe 1-x ) c be d ] 100-y Cu y In the alloy system, a=36%; b=33%; c=6%; d=25%; x=1; y=7 (denoted as ZT2, atomic percentage). The ZT2 master alloy ingot with a mass of 150g has a single amorphous structure, such as figure 2 shown.

[0038] Thermodynamic characteristics: glass transition temperature is 611K; initial crystallization temperature is 652K; liquidus temperature is 1003K; supercooled liquid zone width is 41K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Initial crystallization temperature | aaaaa | aaaaa |

| Liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com