Additive M4228 for polymers

A technology of additives and polymers, applied in the field of additives, can solve the problems of additive consumption, increase of energy consumption per unit of production pipe material, impact on human health, etc., and achieve the effect of improving service life and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

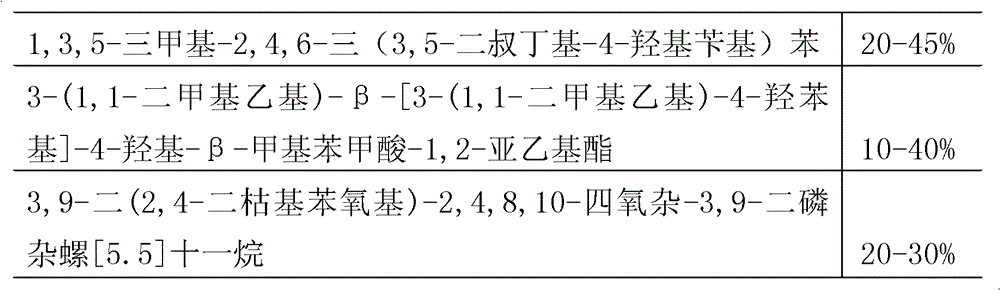

[0021] The proportion of each component of the additive is as follows:

[0022]

[0023] Additive preparation method is as follows:

[0024] After mixing and stirring the above raw material components for 30 minutes, under the protection of nitrogen, heat at 1 atmosphere pressure and 180°C until the components melt, stir for 30 minutes, cool and pulverize the obtained product, pass through a 200-mesh sieve, and collect the part under the sieve to obtain Additive M4228.

Embodiment 2

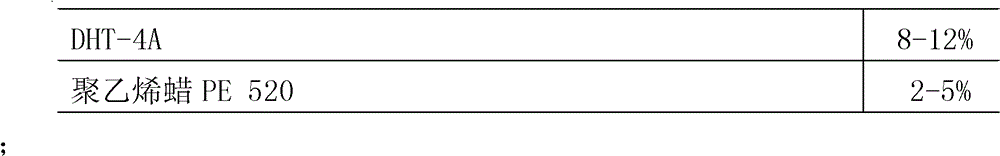

[0026] Additive preparation method and condition are the same as embodiment 1, and each component distribution ratio is as follows:

[0027]

Embodiment 3

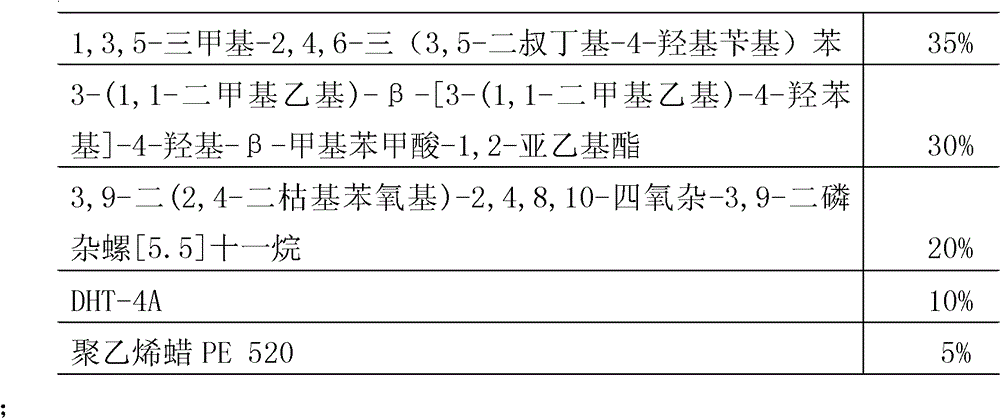

[0029] Additive preparation method and condition are the same as embodiment 1, and each component distribution ratio is as follows:

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com