Tooling for machining steam turbine condenser air extraction pipe

A technology for condensers and steam turbines, applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of low drilling success rate, high scrap rate, scrapped processed tubes, etc., and achieve drilling success efficiency High, high position accuracy, not easy to scrap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

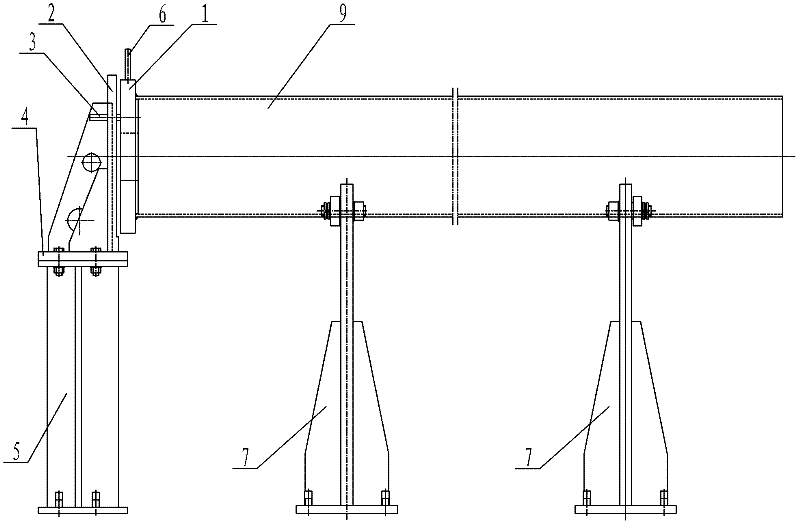

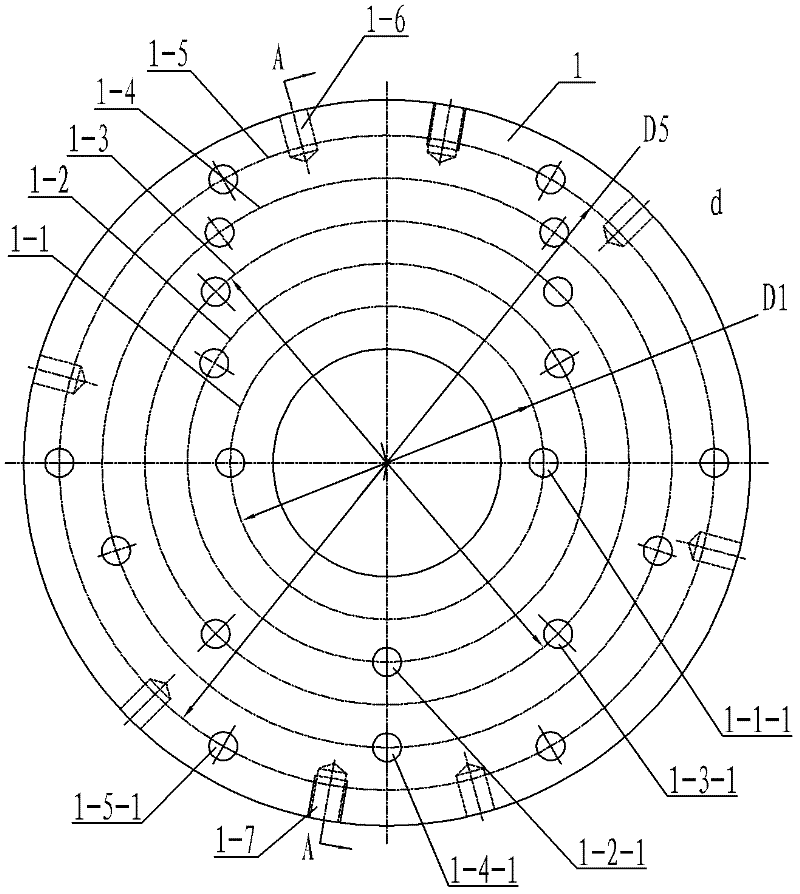

[0007] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment, this embodiment comprises indexing plate 1, positioning plate 2, positioning pin 3, seat plate 4, supporting base 5, at least one rotating rod 6 and two support frames 7, on described indexing plate 1 is made up of There are five pitch circles with increasing diameters concentrically from the inside to the outside. The five pitch circles are the first pitch circle 1-1, the second pitch circle 1-2, and the third pitch circle. 1-3, the fourth pitch circle 1-4 and the fifth pitch circle 1-5, the distance between each adjacent two pitch circles is equal, and the first pitch circle 1-1 is laid There are at least two first indexing holes 1-1-1, several second indexing holes 1-2-1 are evenly arranged on the second indexing pitch circle 1-2, and several second indexing holes 1-2-1 are arranged on the third indexing pitch circle 1-3. Several third indexing holes 1-3-1 are evenly distribute...

specific Embodiment approach 2

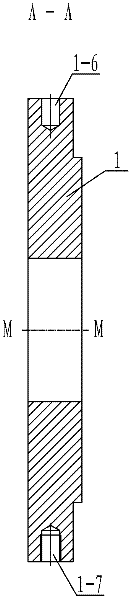

[0009] Specific implementation mode two: combination figure 2 and image 3 To describe the present embodiment, at least one threaded hole 1-7 is provided on the circumferential surface of the index plate 1 of the present embodiment. The threaded holes 1-7 are used to install suspension rings, which is convenient for lifting the indexing plate 1. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination image 3 This embodiment is described. The difference between this embodiment and the first embodiment is that it also adds ribs 8 . Rib 8 plays the role of supporting positioning plate 2 . Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com