A melt protection device and method

A technology for protecting device and melt, applied in the field of new materials, can solve the problems of easy oxidation of melt, limited space of argon gas for protection, thinning of argon gas protective layer, etc., so as to reduce or melt oxidation problems and avoid melt Oxidation problems, the effect of reducing the chance of melt oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

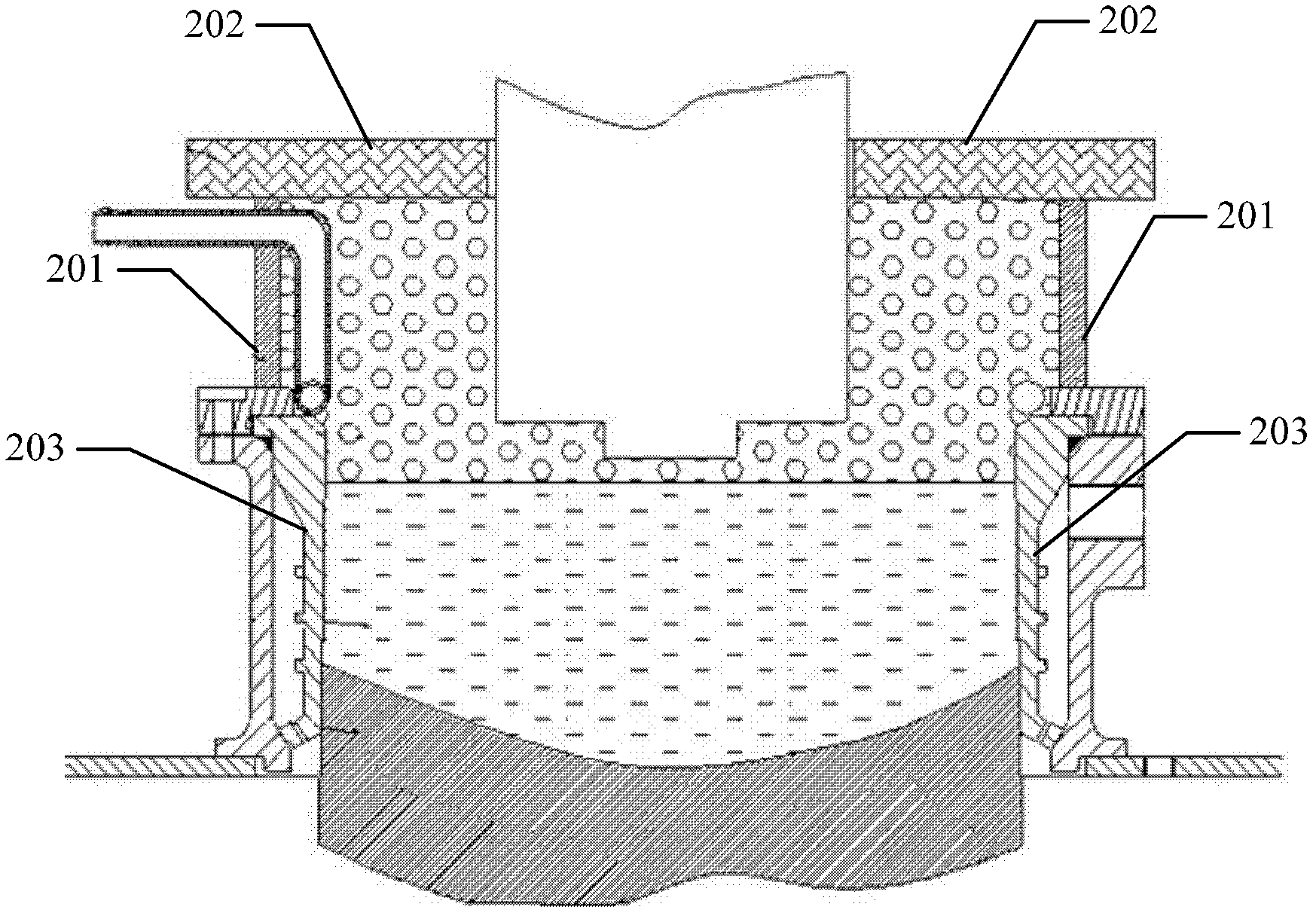

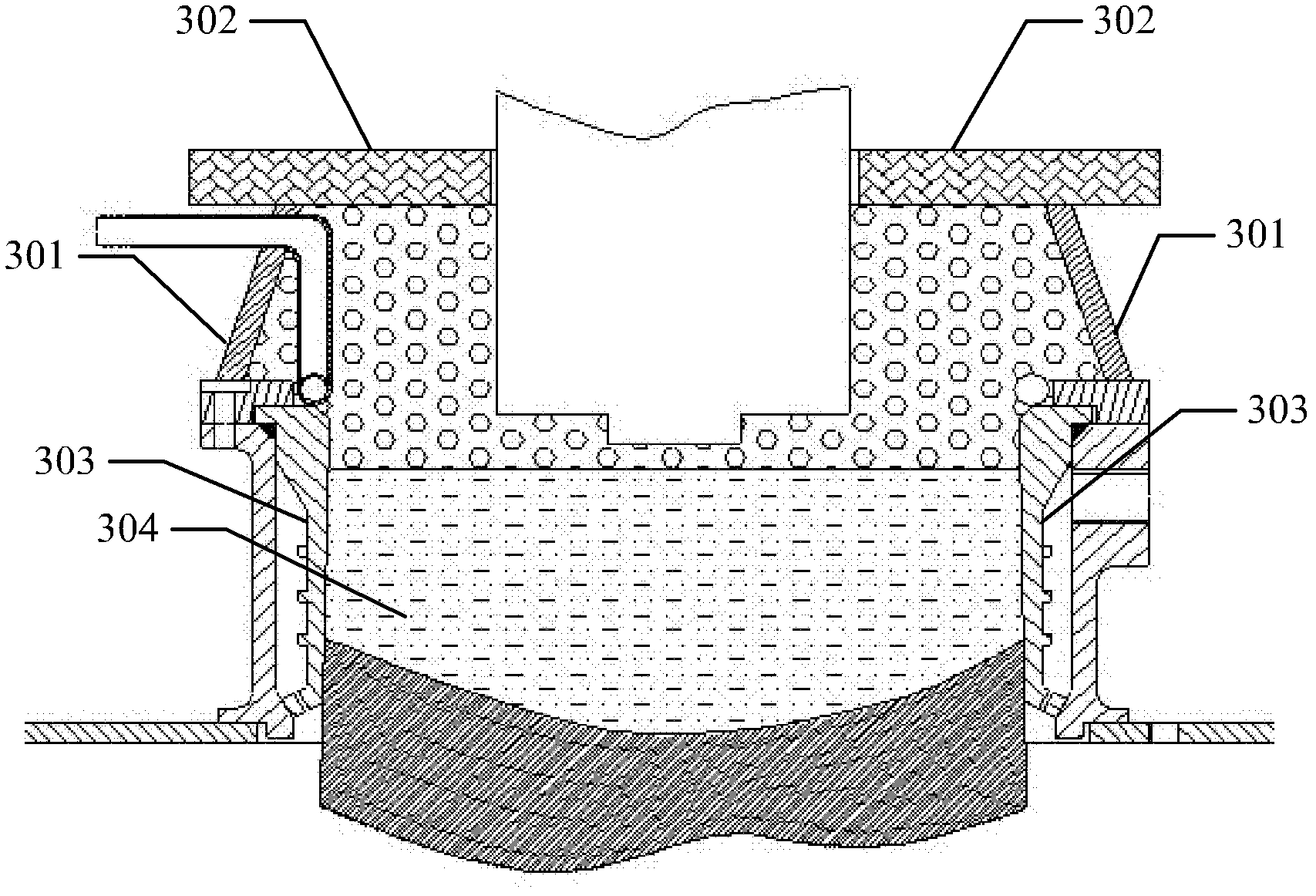

[0013] Embodiments of the present invention provide a melt protection device and method, which are used to prevent melt oxidation and improve internal metallurgical quality. The following are detailed introductions respectively.

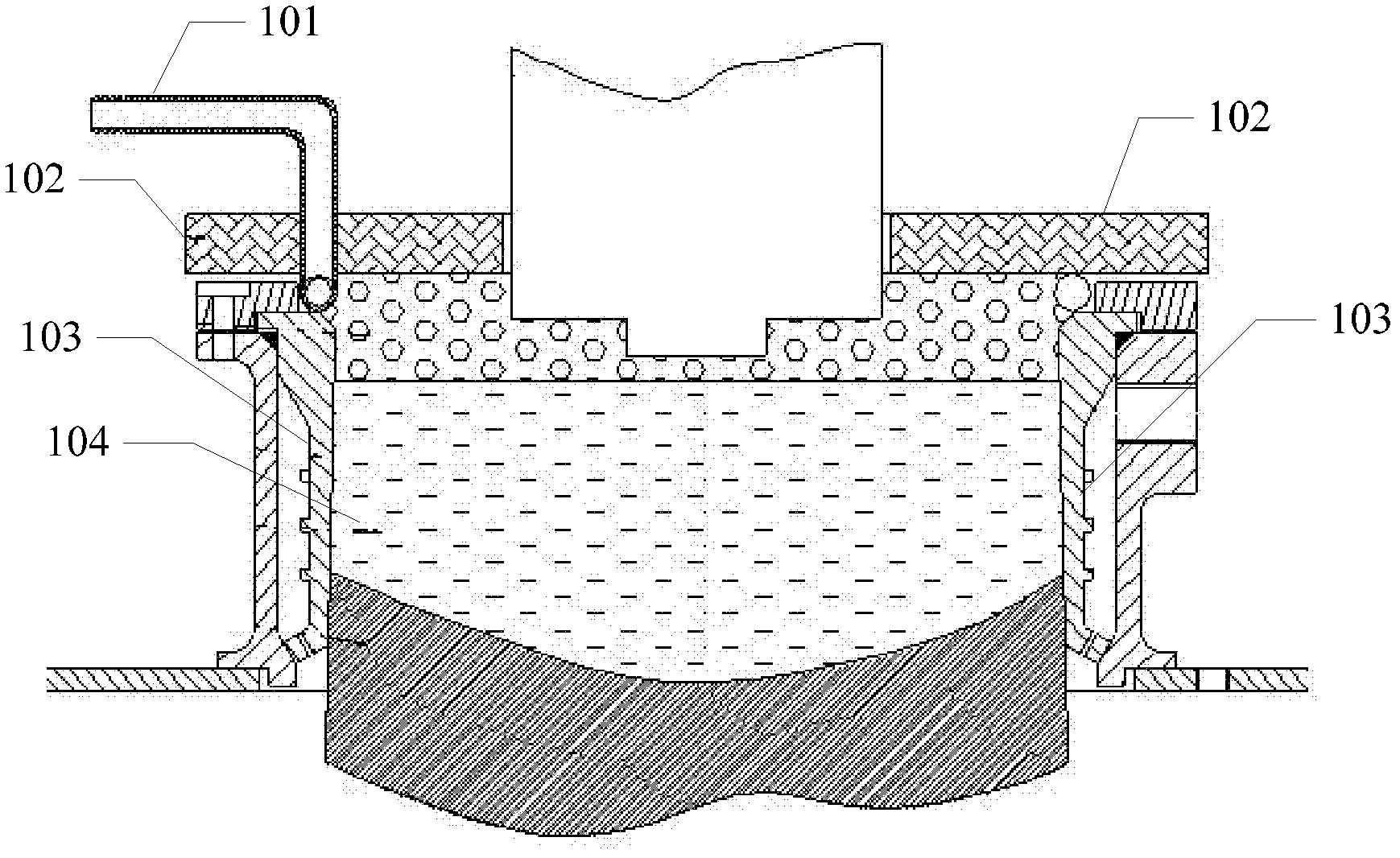

[0014] Firstly, a brief introduction to the prior art melt protection devices and specific protection methods, the aluminum-lithium alloy in the molten state is easy to chemically react with oxygen in the air, the melt will burn and oxidize, and the protection of the melt is extremely difficult. At present, aluminum-lithium alloys are generally smelted in an induction furnace under argon protection, and the static furnace uses vacuum / argon protection to process aluminum-lithium alloys. Small and medium-sized aluminum-lithium alloy ingots are cast under argon protection. Under the current round ingot production conditions, the inert argon gas is heavier than air and does not chemically react with aluminum-lithium alloys to isolate the melt in the crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com