Timing measurement device for water cooling temperature of bar

A technology of water penetration cooling and timing measurement, applied in the field of metal rolling, can solve the problems such as the inability to obtain process control bar to control the cooling temperature, the uneven mechanical properties of the strip, and the inability to distinguish temperature data, etc., and achieve accurate and reliable detection temperature. , The effect of improving the uniformity of mechanical properties and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

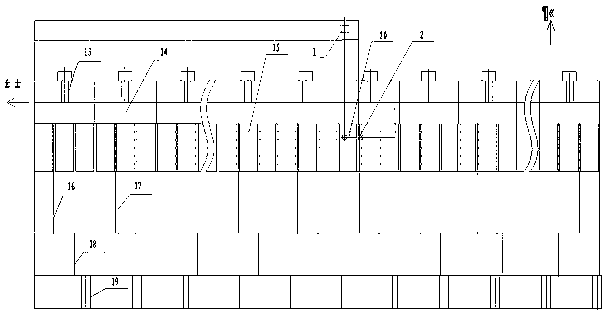

[0015] Depend on figure 1 It can be seen that the cooling bed is connected by the input roller table 13, the cooling bed skirt plate 14, the cooling bed straightening plate 15, the cooling bed fixed rack 16, the cooling bed moving rack 17, the cooling bed collecting chain 18, and the cooling bed output roller table 19. Composition, the high-temperature radiation thermometer is set on the upper bar side of the cooling bed, the balance pedal 3 of the bar temperature detection signal acquisition device 2 is set between the gaps of the two straightening plates, opposite to the high-temperature radiation thermometer, and the bar 20 falls On the balance pedal, collect temperature signals, electric control system and cooling water tank (not marked in the figure).

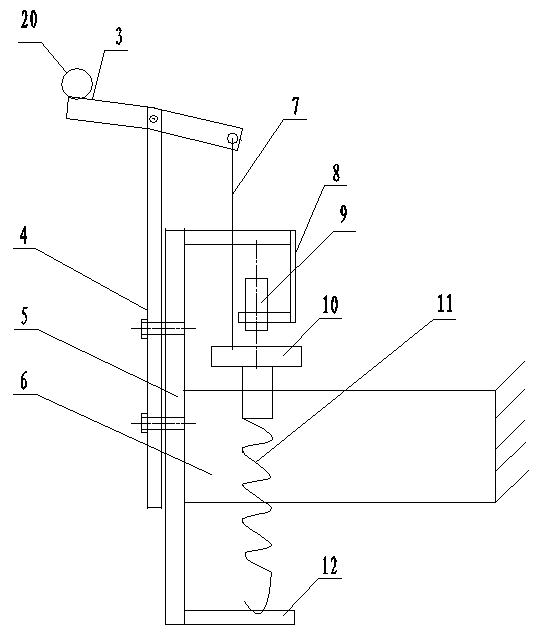

[0016] Depend on figure 2 It can be seen that the timing acquisition device for the temperature detection signal of the bar is composed of a balance pedal 3, a height adjustment rod 4, a bracket and a cooling water beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com