High Speed Vacuum DC Current Limiting Circuit Breaker

A circuit breaker, high-speed technology, used in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of inability to break short-circuit current, lack of current limiting ability, etc., to achieve fast action speed and small fault current. , the effect of derating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

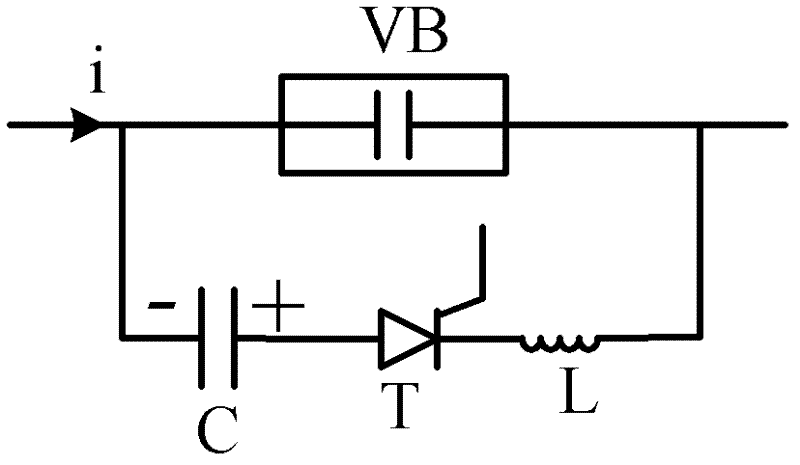

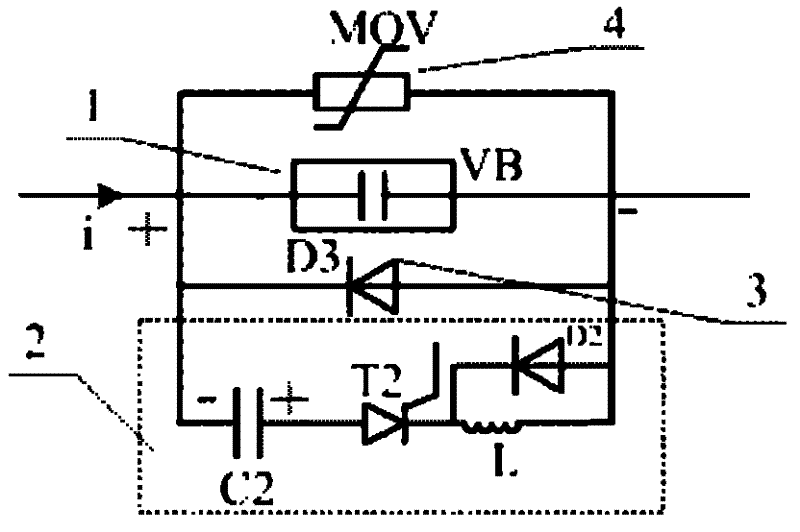

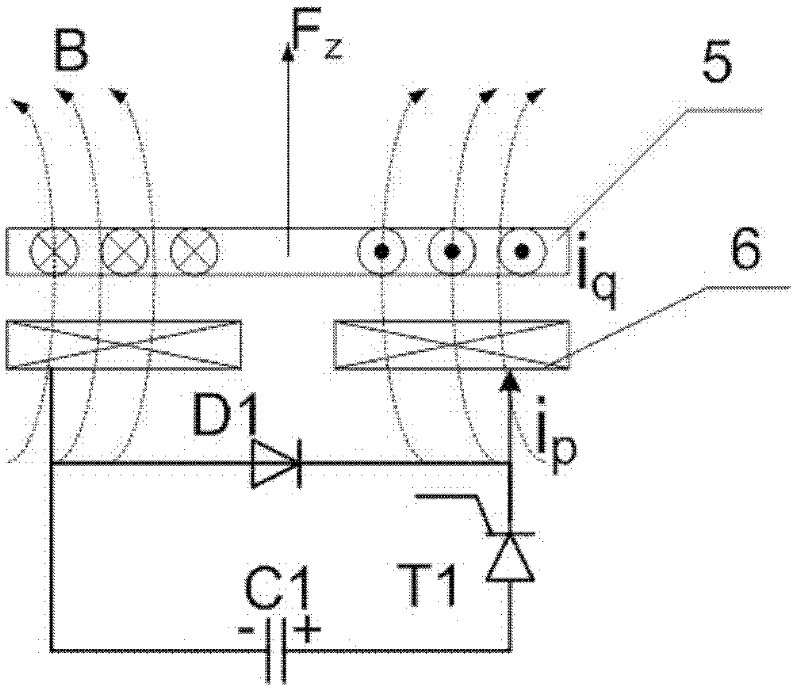

[0023] like figure 2 As shown, the high-speed vacuum DC current-limiting circuit breaker includes a high-speed vacuum contact mechanism 1 for quick opening when receiving an external command, a reverse current generation circuit 2 for creating a current zero-crossing point in the vacuum interrupter, and a The freewheeling circuit 3 for obtaining the zero voltage recovery time after the current in the vacuum interrupter crosses zero and the energy absorbing circuit 4 for absorbing the energy of the circuit, the high-speed vacuum contact mechanism 1, the reverse current generating circuit 2, continued The current circuit 3 and the energy absorbing circuit 4 are connected in parallel, and the energy absorbing circuit 4 may be a piezoresistor or other electronic components with energy absorbing function or a combination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com