Solid elastic lens element and method of manufacturing the same

一种透镜、元件的技术,应用在透镜元件领域,能够解决光学系统小型化和节能限制等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

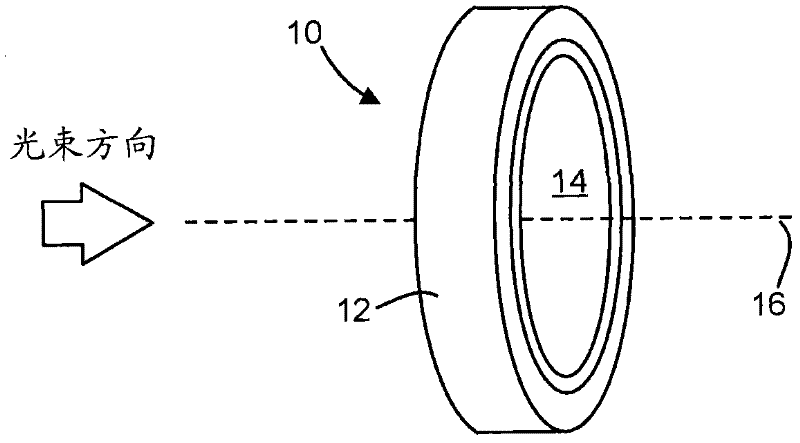

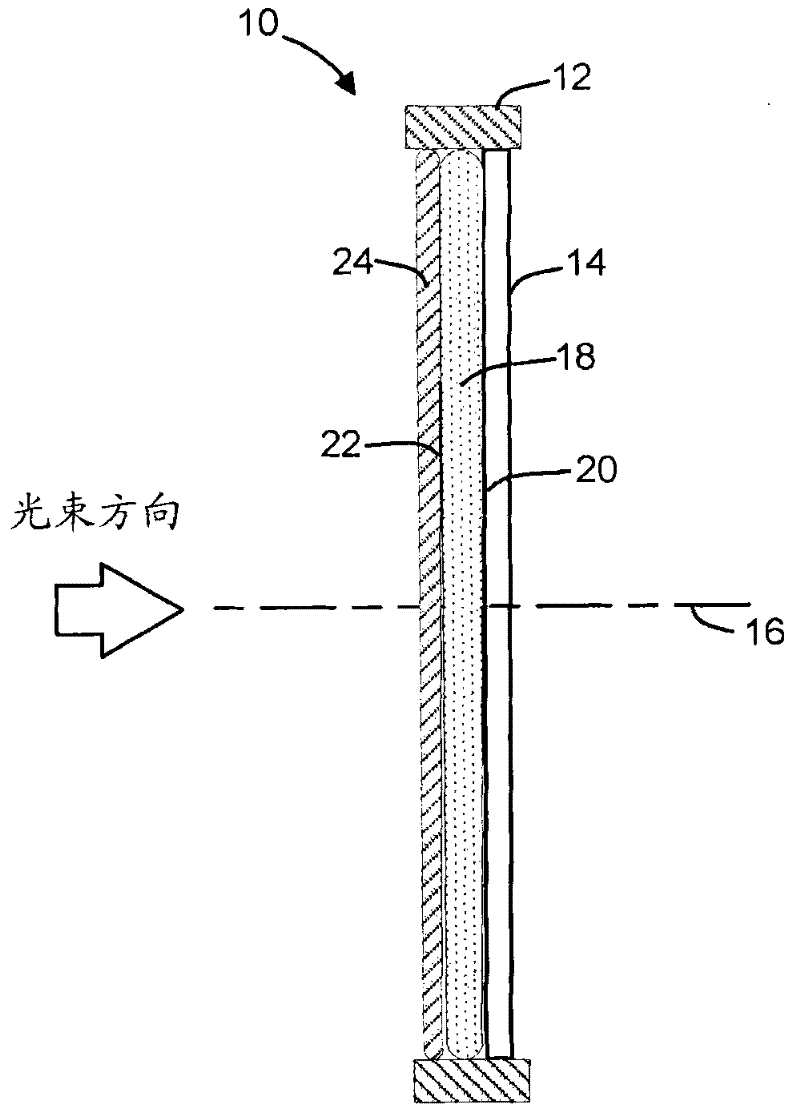

[0041] refer to figure 1 with 2A , respectively show a perspective view and a cross-sectional side view of the lens element 10 . The lens element 10 includes a housing 12 , two light-transmitting elastic solid lenses and a light-transmitting cover 14 . In the illustrated embodiment, the housing 12 is a simple annular structure into which the cover 14 is press fit. The two lenses nest together against the cover 14 . Other configurations of housing 12 are possible and will be described in detail below. The two elastic solid lenses and cover 14 together define an optical axis 16 .

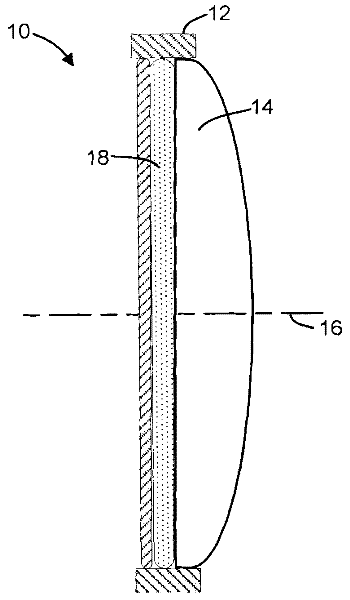

[0042] The light transmissive cover 14 may be provided by a solid light transmissive material with or without optical power, or by a deformable membrane capable of exhibiting a curvature for defining a lens surface with optical power, such as in Figure 2B shown in . In the illustrated embodiment, the light-transmissive cover 14 is a solid sheet of glass.

[0043] A first elastic solid lens 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com