Test method and special tooling for static lubrication flow distribution of fixed shaft gearbox shaft

A test method and flow distribution technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as the inability to guarantee the optimal design, and achieve the effects of low tooling cost, convenient and quick replacement, and short test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

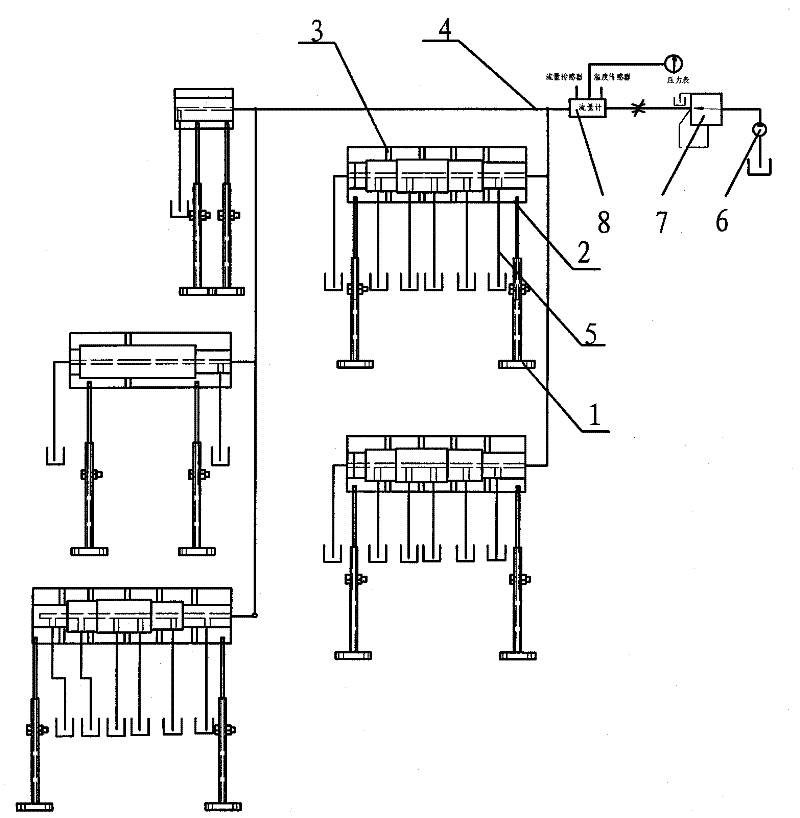

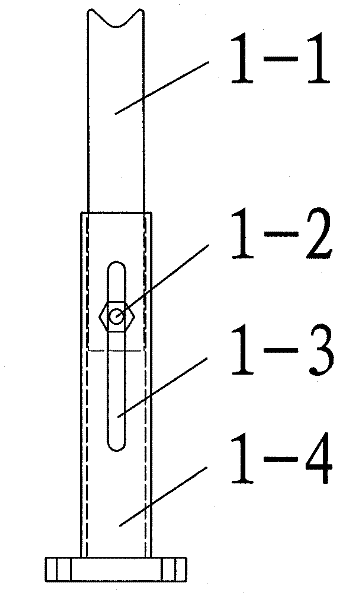

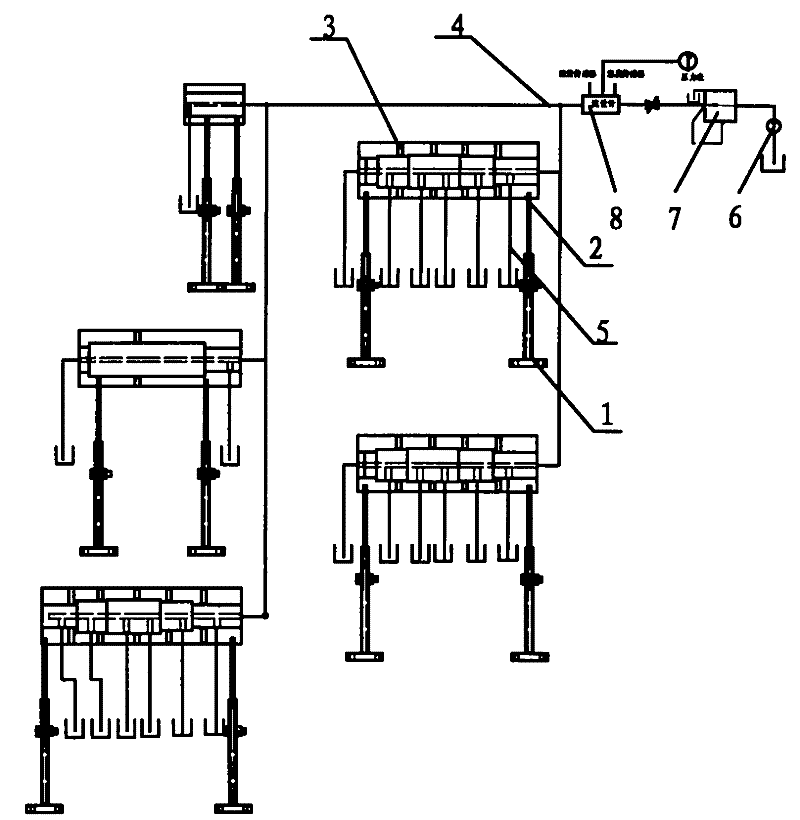

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The test method is as follows: first, a small hydraulic loading pump station with a multi-stage decompression circuit is needed to act as a quantitative pump to provide lubricating oil with fixed parameters for the test, and the oil outlet of the pump station is connected with a pressure sensor and a flow sensor. By adjusting the overflow valve knob to change the flow rate and pressure of the oil outlet of the pump station to the value required by the test, the pump station is ready for use; secondly, the shaft to be tested is separated from each oil outlet with a rubber sealing ring, and placed in a transparent In the plastic shaft shell, each oil outlet is connected with a hose, and the pipeline is connected according to the system schematic diagram. According to the design, each lubrication hole is named and marked separately. The oil outlet of each hose can be freely placed in the oil tank or large capacity measuring cup.

[0022] The specific test ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com