Clamping vibration device for integral torsional fatigue test of crankshaft

A technology of torsional fatigue and vibration excitation device, applied in the direction of machine gear/transmission mechanism testing, etc., to achieve the effect of easy clamping and disassembly, simple manufacturing and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

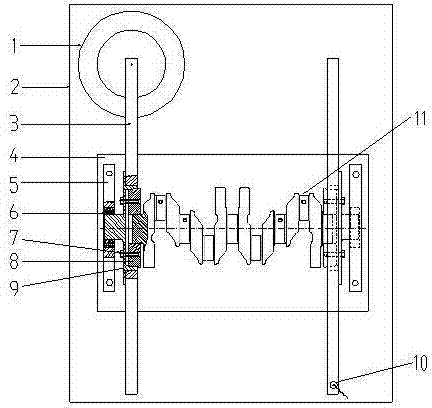

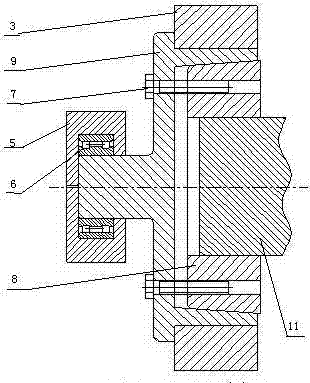

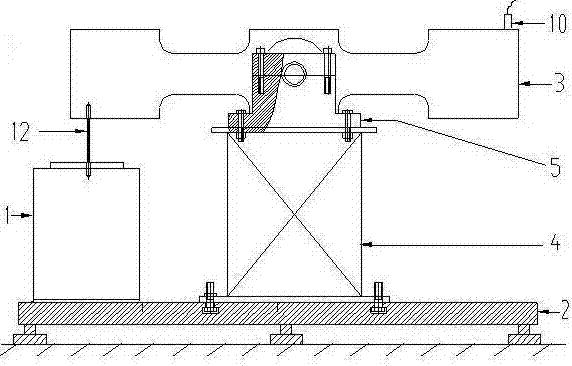

[0015] From figure 1 , figure 2 , image 3 It can be seen from the figure that a crankshaft overall torsional fatigue test clamping vibration excitation device includes a base 2, a vibration exciter 1, two vibration plates 3, a test bracket 4, and a fixture 5. The vibration exciter 1 is fixed on the base 2, and connected with a vibrating plate 3 through a push rod 12.

[0016] The test bracket 4 is fixed on the base 2, and the test bracket 4 is made of ordinary carbon steel plate, which is fastened on the base 2 with bolts and located in the center of the base 2. Two clamps 5 with bearing sockets are fixed on both sides of the test bracket 4 . There is a through hole in the middle of the vibrating plate 3 made of ordinary carbon steel plate, and an outer connection sleeve 9 is installed in the through hole with an interference fit. The inner side of the cover 9 is connected with an inner connecting sleeve 8, and the main journals at both ends of the crankshaft 11 are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com