Orange nylon active dyestuff and preparation method thereof

A reactive dye and nylon technology, applied in the field of nylon reactive dye and its preparation, can solve the problems of low absorption rate, poor wet fastness of nylon, and high concentration of dyeing waste liquid, and achieve high absorption rate and lifting rate, wet Excellent fastness performance, bright and beautiful color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

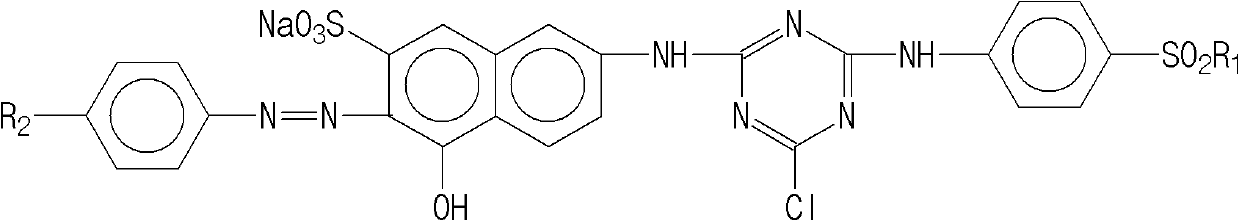

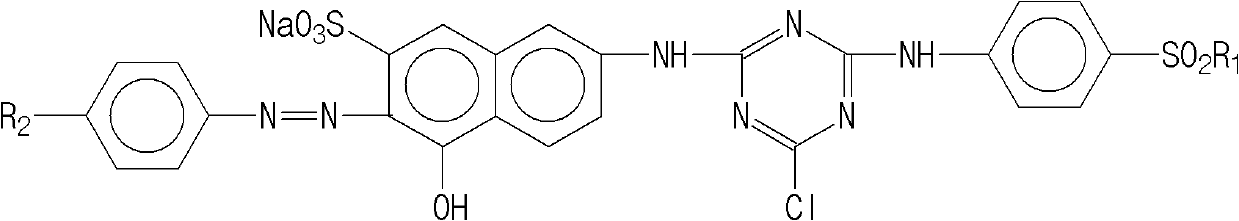

Image

Examples

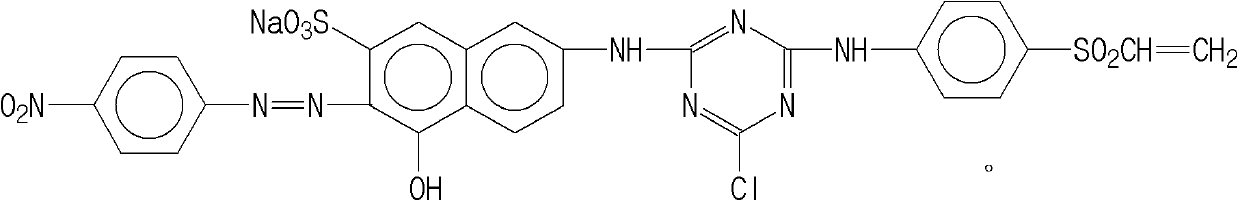

Embodiment 1

[0051] An orange nylon reactive dye has the following structural formula:

[0052]

[0053] The preparation method of above-mentioned nylon reactive dye orange comprises the steps:

[0054] a. Dissolution of p-beta-hydroxyethylsulfone sulfate aniline: add 2000 liters of water to the reaction tank, then add 301kg p-beta-hydroxyethylsulfone sulfate aniline, stir evenly, adjust pH=3.8 with sodium bicarbonate -4, obtain p-β-hydroxyethyl sulfone sulfate aniline solution, for subsequent use;

[0055] b. Shrinkage reaction: add 1000 liters of water, 2500Kg of crushed ice in the reaction tank, stir, add 188kg of cyanuric chloride, and after ice grinding for 15 minutes, start to drop the p-β-hydroxyethyl sulfone sulfuric acid prepared in step a After the addition of the ester aniline solution, the pH was maintained at 2-4 with sodium bicarbonate, and the temperature was maintained at 6-8°C. After 5 hours of reaction, a shrinkage reaction solution was obtained. spare;

[0056] c, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com