Full-automatic flow passage shearing machine

A fully automatic shearing machine technology, applied in the field of automatic flow channel shearing machine, can solve the problems of increasing production cost, unstable quality, and many defective products, and achieves the goal of ensuring quality, high automation and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

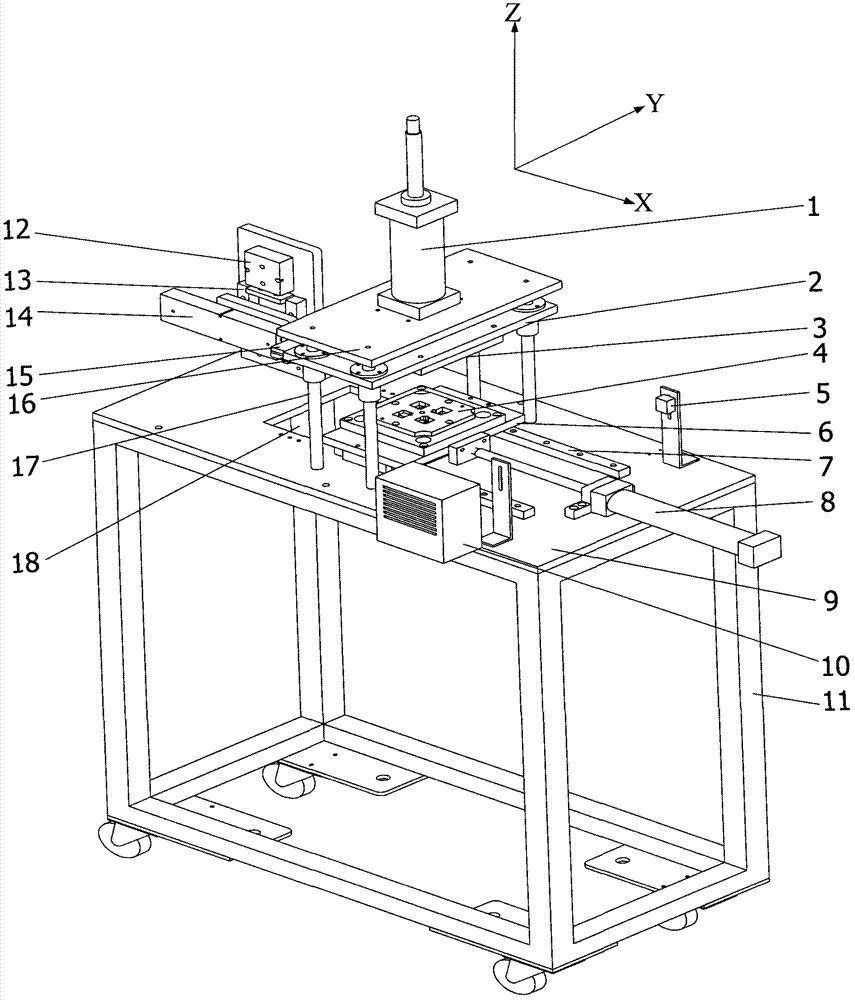

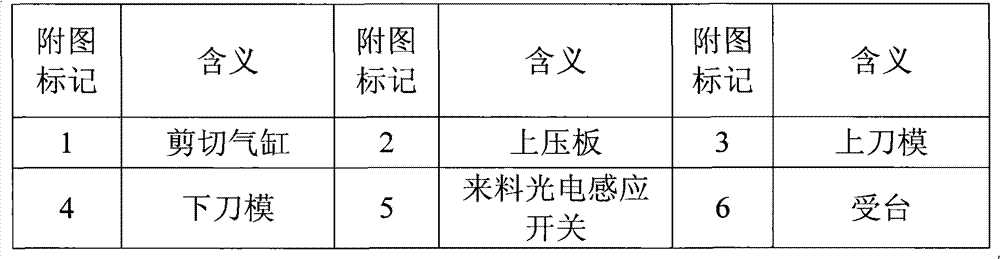

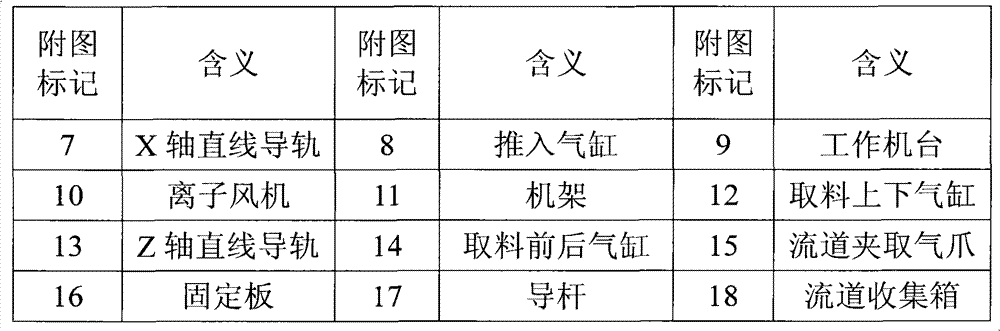

[0015] In order to cut the runner according to the product requirements, it is necessary to install a fully automatic runner cutting machine next to the forming machine, which mainly includes the product receiving table part, the shearing device part and the runner taking out device part. Equipped with the corresponding shearing knife die, after the product and the flow channel are positioned, the knife die enters the shearing area for shearing, and at the same time separates all products from the flow channel. After cutting, the flow channel is automatically discarded to the flow channel collection position , the products are respectively opened into the corresponding numbered product boxes, so that the quality consistency of the products after cutting can be increased to 100%, and the defect rate is 0, which can realize fully automatic production in an unmanned state.

[0016] Such as figure 1 As shown in the full-automatic flow channel shearing machine, a working machine 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com