A punching method with continuous die upwards

A punching and die technology, which is applied in the field of continuous die punching in cold stamping production, can solve the problems of inability to complete continuous punching, the lower die cannot be used as a cutting edge, and burrs are generated, and achieves a simple structure, easy operation, and reduced production. The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

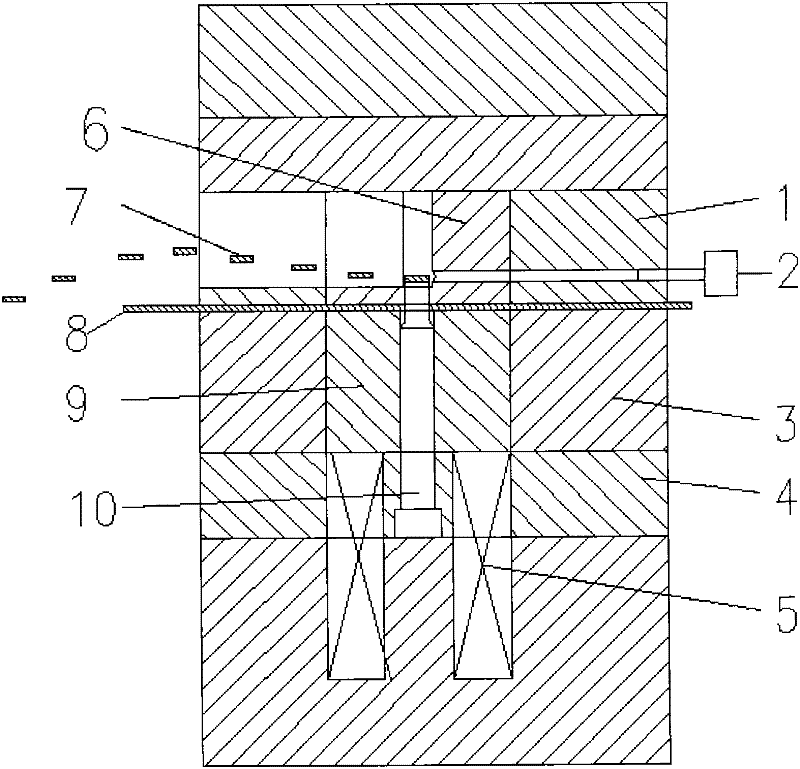

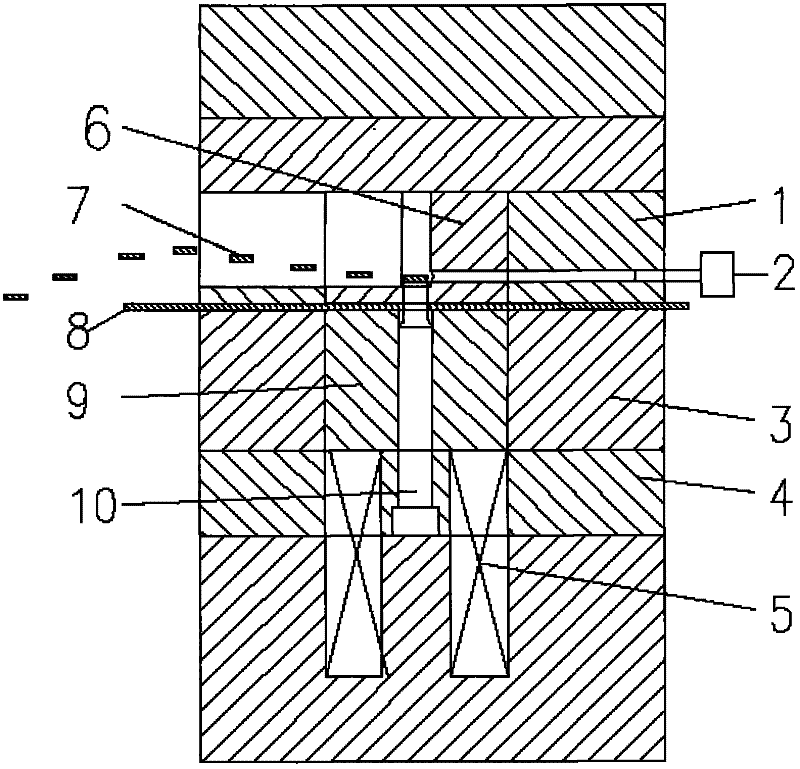

[0009] In the accompanying drawings, the punch (10) is fixed on the lower backing plate (4), the lower backing plate (4) plays the role of splint fixing, the lower template (3) is designed to be movable and elastic into the block (9), and the stripping plate ( 1) Design the cutting edge into the block (6). When punching, the stripping plate (1) goes down, so that the elastic inserting block (9) goes down together, and the spring (5) is compressed and presses the stripping plate (1) and the elastic Put the material (8) in the middle of the block (9) and then punch it out. After the mold is closed, the punching is completed, the stripper plate (1) goes up, the compressed spring (5) returns to its original state, and the elastic The input block (9) is ejected, so that the material (8) is separated from the punch (10), and the upper part of the cutting edge input block (6) is evacuated, and the punched waste (7) goes out from the evacuated position, and the air blowing device (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com