Rubber seal drying and screening all-in-one machine

A technology of rubber seals and integrated machines, which is applied in the direction of dryers, drying, and drying solid materials, etc., can solve the problems of large investment, long operation time, and large workshop area of the two sets of equipment, and achieve low noise and labor efficiency. Improve the effect of small site area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

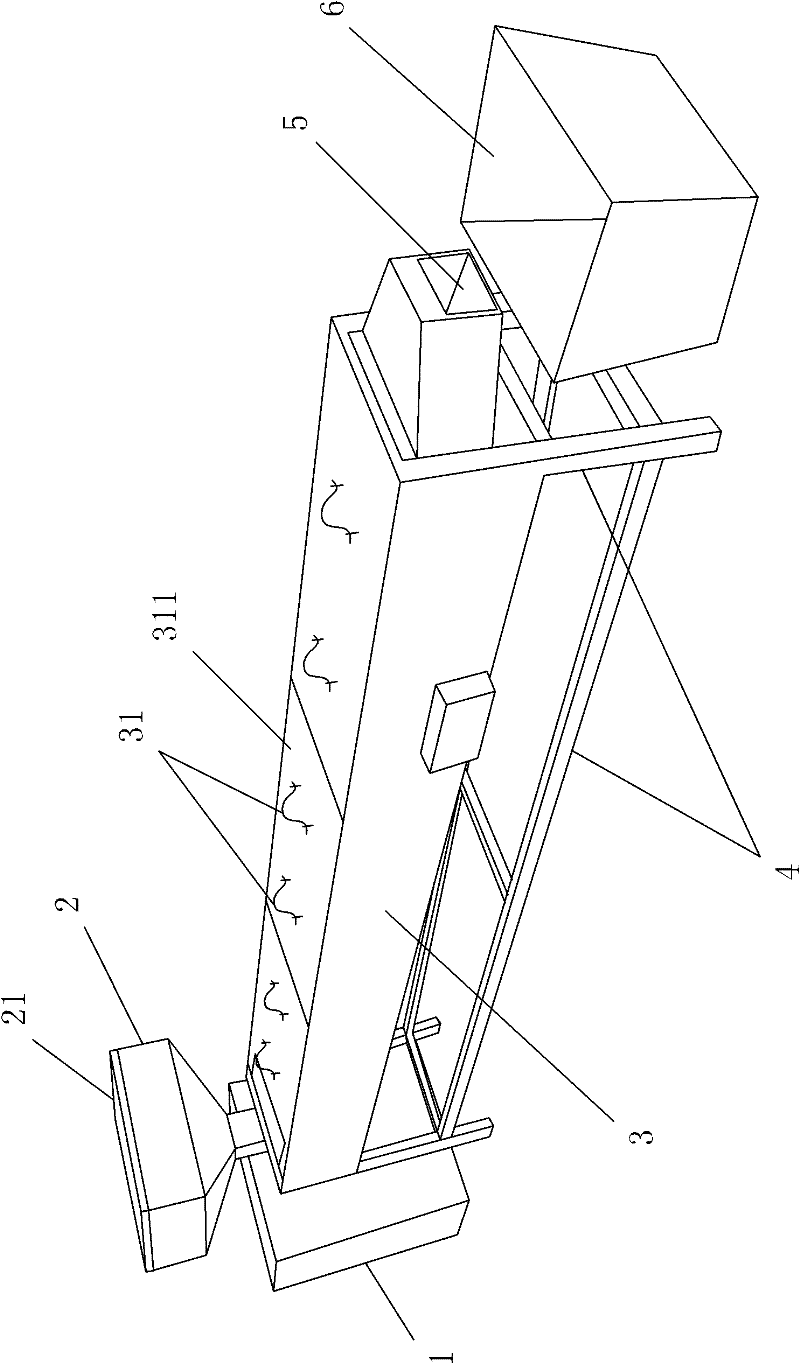

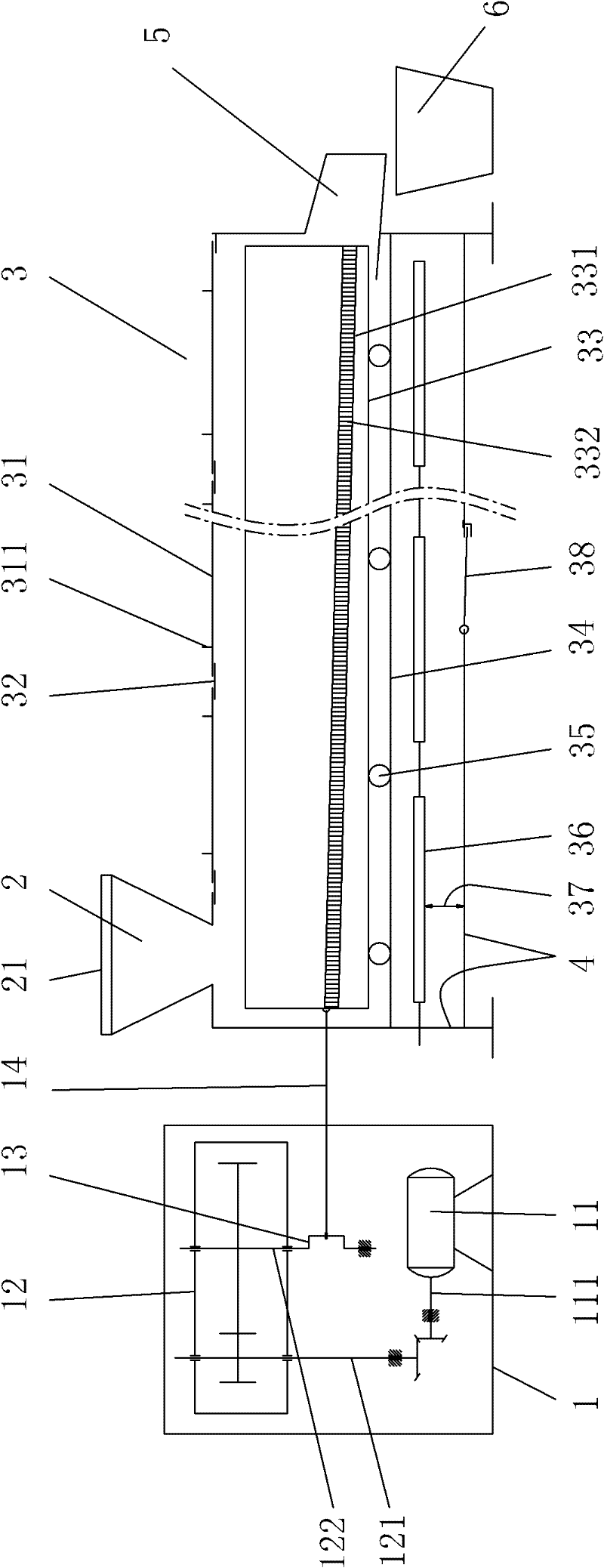

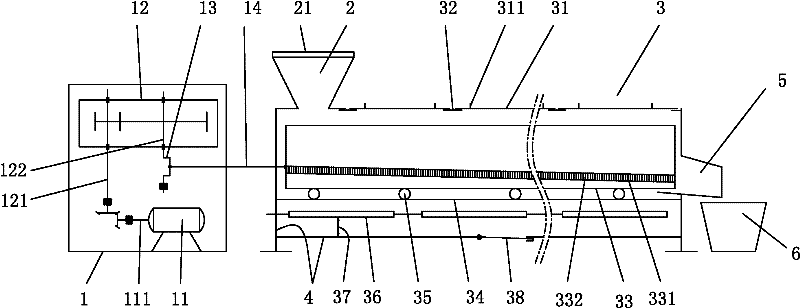

[0021] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-2 :

[0022] Rubber seal drying and screening all-in-one machine, a heater 36 is arranged at the bottom of a rectangular box 3, and a swaying sieve 33 with a sieve part 331 is supported on the heater 36 through a slide rail 34. The sieve part of the sieving part 33 The lower end is provided with a discharge port 5 protruding from the box body 3, the upper part of the box body on the high side of the sieve part of the shaking screen 33 is provided with a feed port 2, and the upper part of the box body 3 is provided with more than one upper cover 31, The high end side of the sieve portion of the shaking screen 33 is provided with a driving mechanism 1 that drives the shaking screen 33 to rock back and forth.

[0023] The above-mentioned driving mechanism 1 is as follows: the motor shaft 111 driven by the motor 11 is connected to the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com