A pulsed fracture healing whole process stress measurement device

A technology for fracture healing and stress measurement, applied in sports accessories, muscle training equipment, gymnastics equipment, etc., can solve problems such as inconsistency, achieve low cost, reduce surgical experience requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

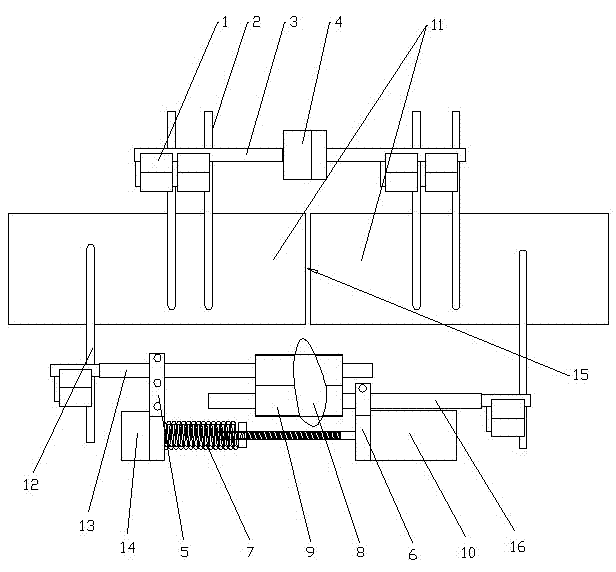

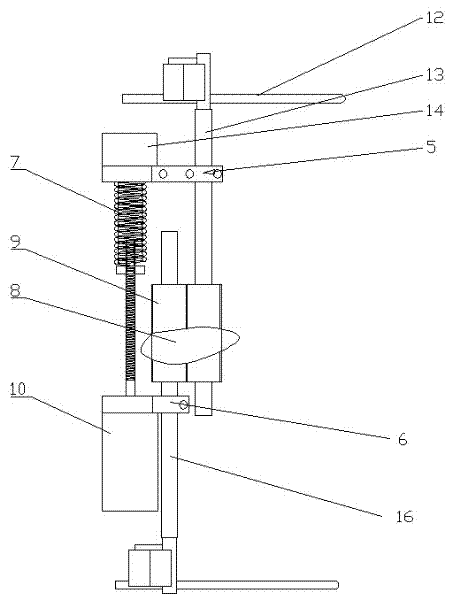

[0027] see Figure 1 to Figure 5 According to the embodiment of the present invention, the pulse-type stress measurement device for the whole process of fracture healing includes a fixed bracket, a fixed bracket pressure indicator, a pressurized bracket, a pressurized bracket pressure indicator, a pressurized bracket control module, and a computer.

[0028] It works as follows:

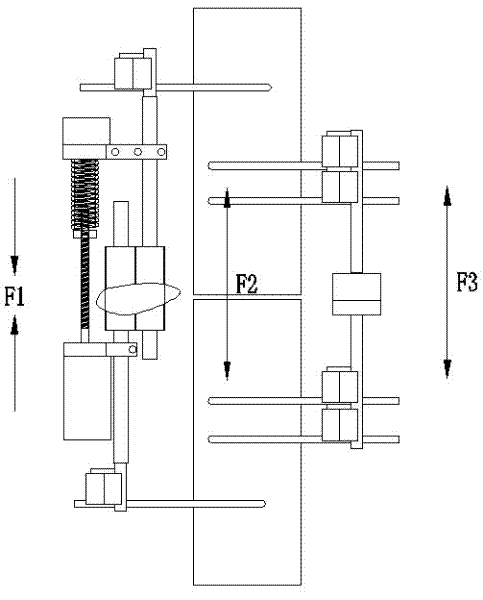

[0029] During the experiment, during each pulse pressurization, the pressurized support generates a pressure F1, and the fixed support and the bone generate reaction forces F3 and F2 respectively. Since these three forces are all axially in the same direction, their relationship is F1 = F2+F3 . The pressure F1 and F3 can be obtained in the experiment, so the required force F2 = F1-F3 on the bone can be simply obtained. At the initial stage of the fracture, when the bracket is just installed, F3 will bear all the pressure of F1. As the fracture slowly heals, F2 will become bigger and bigger. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com