Dishes washing and disinfection line

A technology for cleaning and disinfecting dishes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

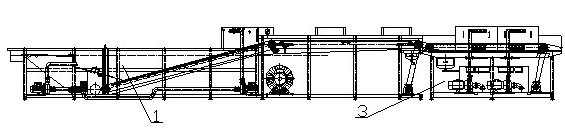

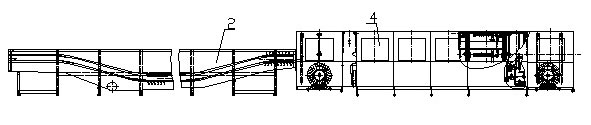

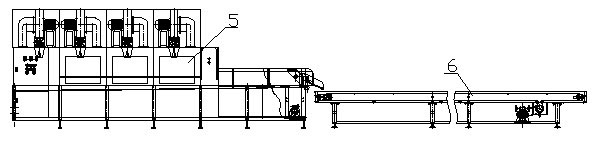

[0021] The specific implementation of the dish washing and disinfection line of the present invention will be described below in conjunction with the accompanying drawings.

[0022] Such as Figure 1 to Figure 3 As shown, the dish cleaning and disinfection line of the present invention includes a water-passing type classification and deslagging machine 1, a rough washing and deslagging machine 3, an ultrasonic soaking and disinfection machine 2, a washing machine 4, a drying machine 5 and a sorting and conveying machine connected in sequence. Machine 6.

[0023] see Figure 4 As shown, the above-mentioned water-type classification and slag removal machine 1 includes a slag removal tank 14 , a slag collection tank 10 , a centrifugal pump 9 , a first cleaning and spraying device 17 , a first air knife drying device 19 and a conveyor belt 15 . Specifically, the V-shaped pool of the water-transfer type classification slag remover 1 is separated by a partition 11 to form a slag re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com