Tobacco separation device

A technology for separating device and shredded tobacco, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve problems such as inability to apply, and achieve the effects of fast production and assembly, reasonable design and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

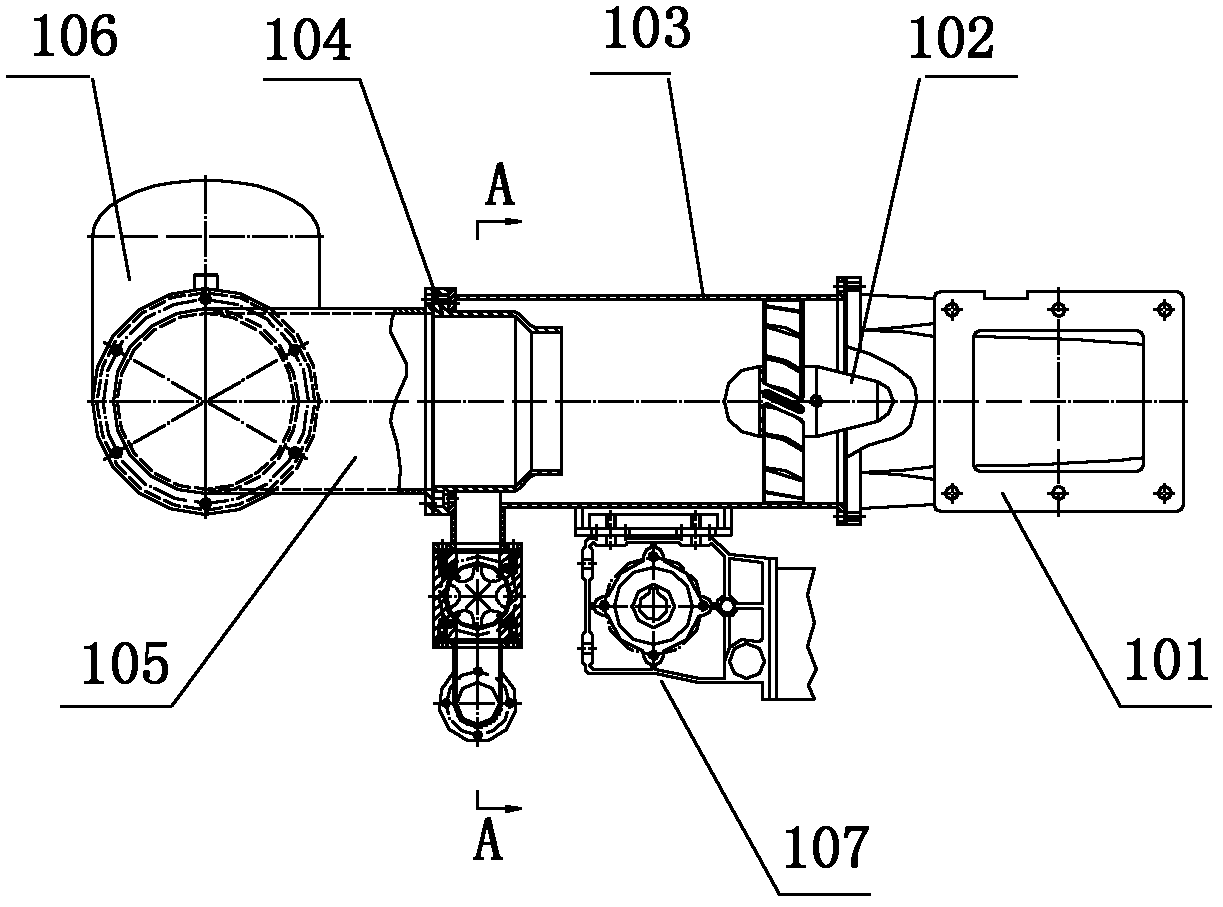

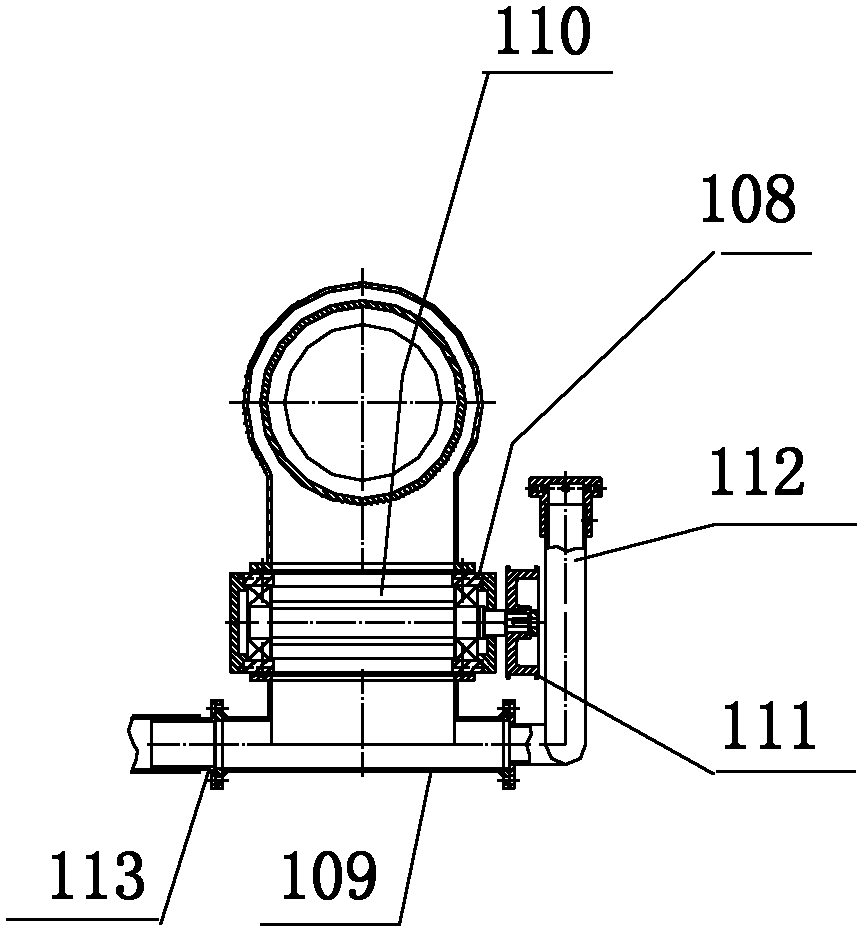

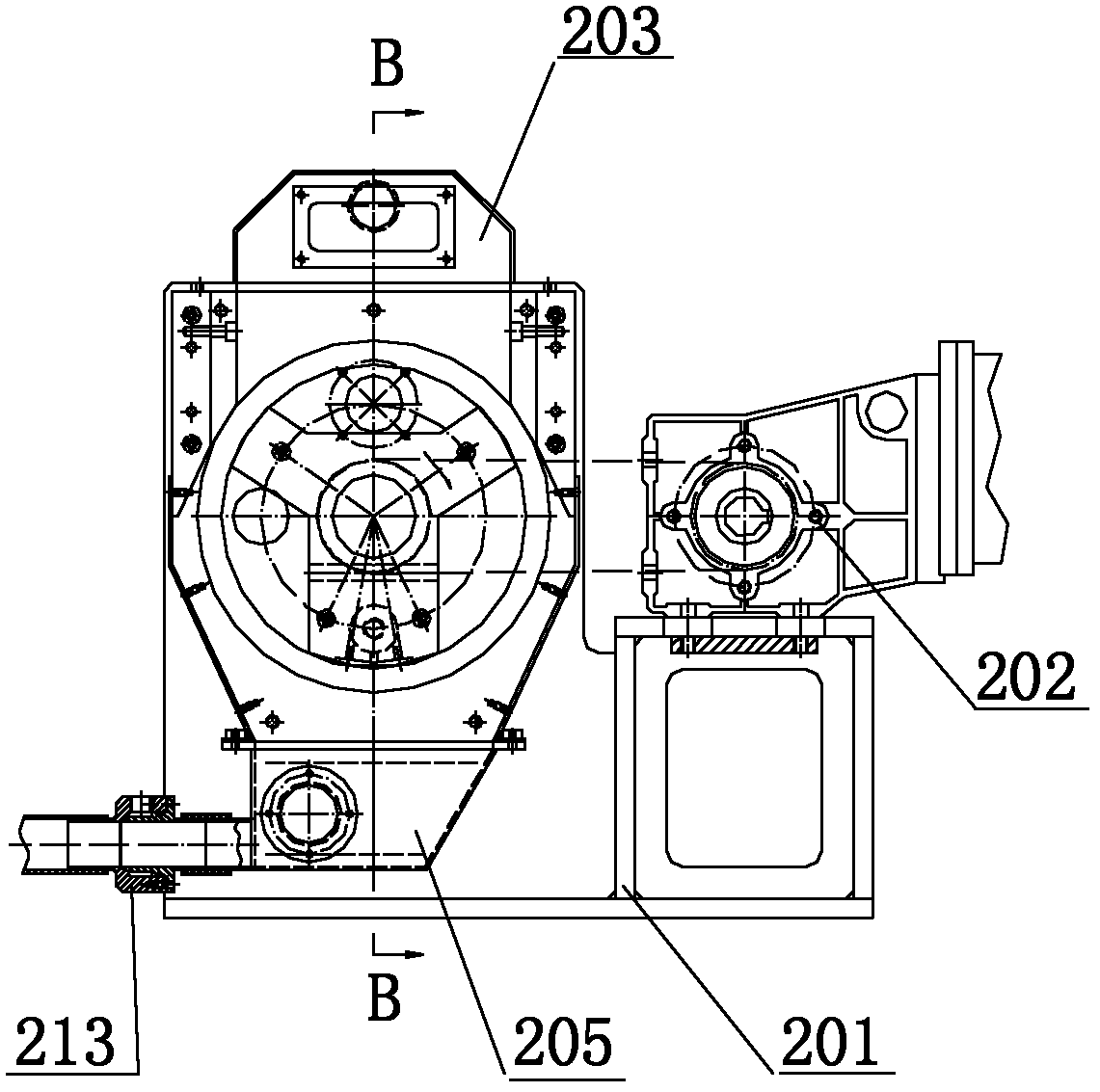

[0022] A shredded tobacco separating device, comprising figure 1 The centrifugal primary separation mechanism shown, image 3 The rotary secondary separation mechanism shown, the hose (not shown) connecting the centrifugal primary separation mechanism and the rotary secondary separation mechanism.

[0023] like figure 1 , figure 2 As shown, the centrifugal primary separation mechanism includes an inlet elbow 101, a guide vane 102, a separation cylinder 103, a guide tube 104, an elbow 105, and an air outlet elbow 106 connected in sequence in a horizontal direction. A drive motor 107 is provided at the lower end of the cylinder 103, a gate body 108 and a doffing hopper 109 connected vertically downwards at the interface between the separation cylinder 103 and the draft tube 104, a star roller shaft 110 is arranged in the gate body 108, and a star roller shaft 110 is arranged in the gate body 108. One side of 110 is provided with a pulley 111 to drive the rotation of the star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com