Seed rolling device and method for rice precision hole direct sowing machine

A technology of rolling device and hole direct seeding, which is applied in the direction of interval quantitative sowing machinery, planter parts, sustainable manufacturing/processing, etc., and can solve the problems of low seed germination rate, small contact surface, and floating and moving seeds , to achieve good anti-adhesion and desorption effects, precise pressure adjustment, and increased sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

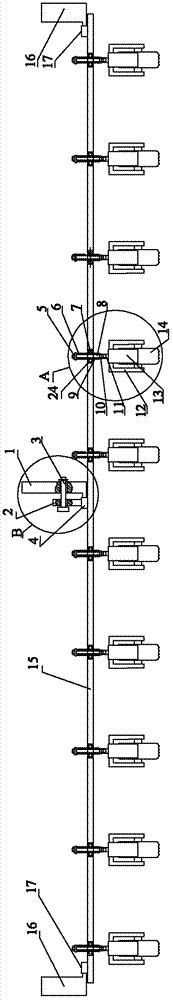

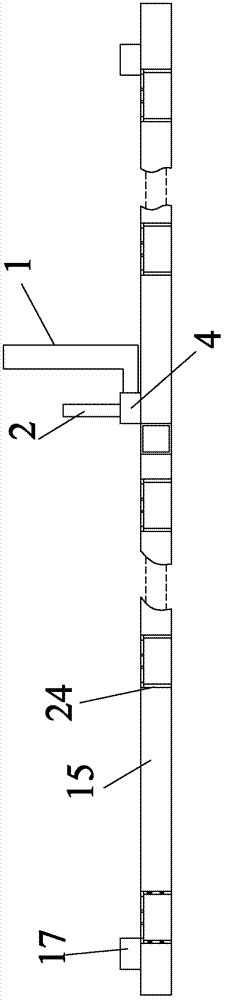

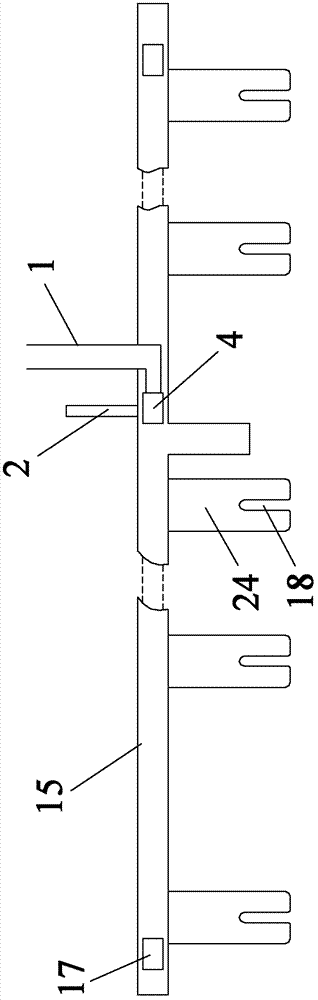

[0042] Figure 1 to Figure 8 A schematic diagram of the specific structure of this embodiment is shown, such as figure 1 As shown in the figure, the seed rolling device of this rice precision hole direct seeding machine includes a frame beam 15, a positioning mechanism and ten rolling mechanisms connected to the frame beam 15, and the two ends of the frame beam 15 are respectively provided with a direct seeding machine. connecting mechanisms such as Image 6 As shown, the connection mechanism of the direct seeding machine is externally connected to the rice precision hole direct seeding machine 22; the positioning mechanism is connected to the center position of the frame beam 15, and is externally connected to the rice precision hole direct seeding machine 22; as shown in the figure. figure 2As shown, the front side of the frame beam 15 is connected with ten rolling installation frames 24 corresponding to each rolling mechanism one by one, as image 3 As shown, and each ro...

Embodiment 2

[0062] This embodiment has the same characteristics as Embodiment 1 except the following features: the diameter of the mounting hole is 5 mm larger than the outer diameter of the bolt; the diameter of the slot-shaped through hole is 3 mm larger than the outer diameter of the adjusting rod.

[0063] In the seed rolling method of the rice precision hole direct seeding machine, the pressing depth of the roller in step (2) is 1.5 cm, and the pressing pressure thereof is 5N.

Embodiment 3

[0065] This embodiment has the same characteristics as Embodiment 1 except the following features: the diameter of the mounting hole is 3mm larger than the outer diameter of the bolt; the diameter of the groove-shaped through hole is 2mm larger than the outer diameter of the adjusting rod.

[0066] In the seed rolling method of the precision hole direct seeding machine for rice, the pressing depth of the roller in step (2) is 0 cm, and the pressing pressure thereof is ON.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com