Chip mounter

A placement machine, patch technology, applied in the direction of electrical components, electrical components, electrical components to assemble printed circuits, etc., can solve the problems of time-consuming and laborious, waste of work area, low work efficiency, etc., to achieve convenient installation and use, improve transmission The effect of speed and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

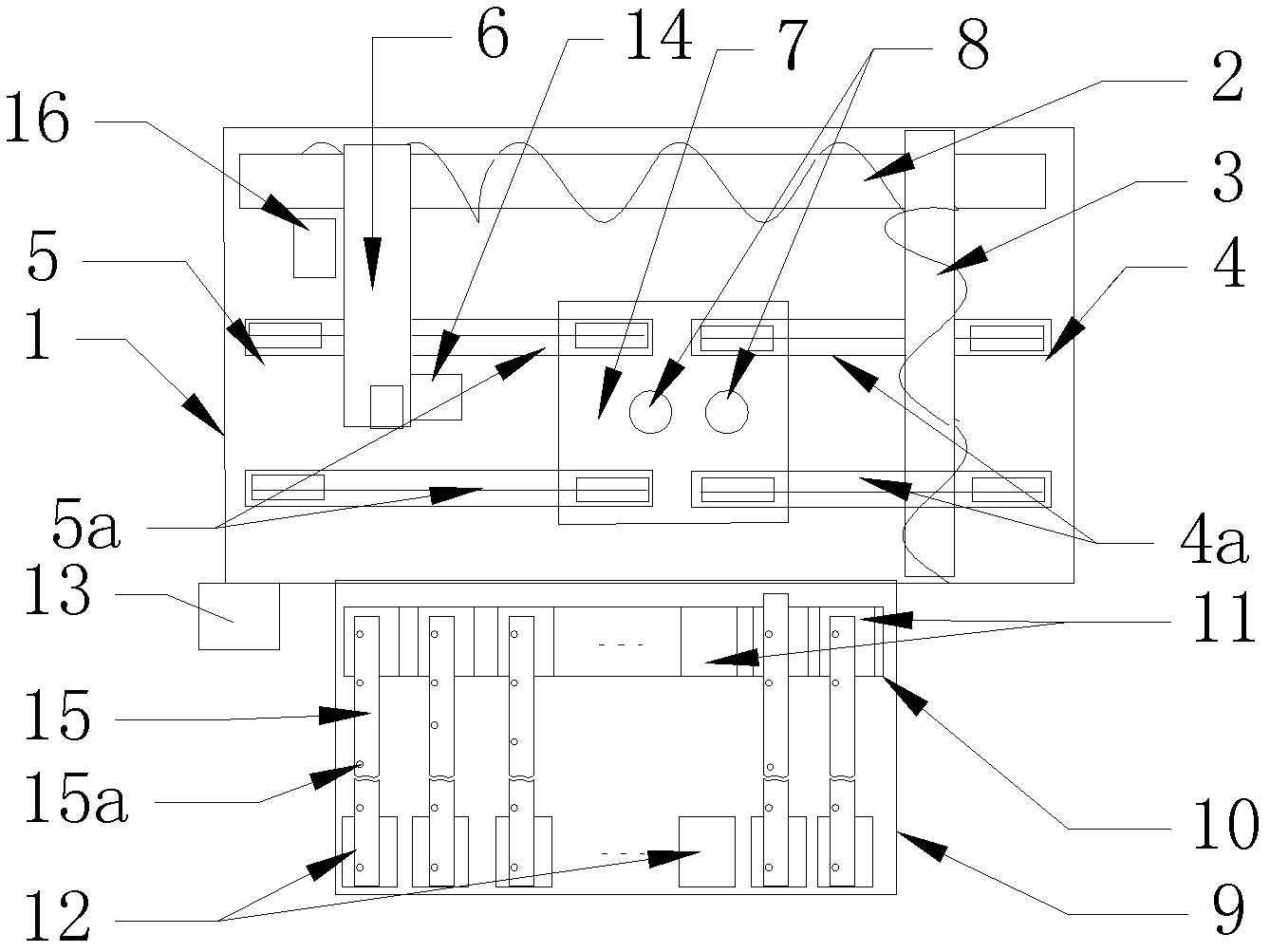

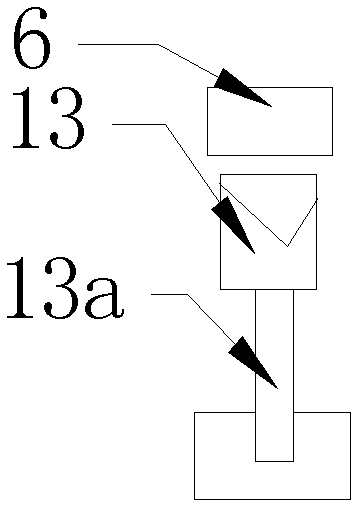

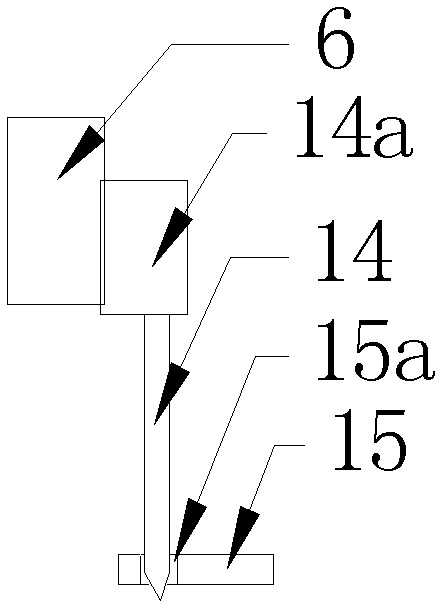

[0019] The present invention will be further described through embodiment now in conjunction with accompanying drawing. like Figure 1-4 As shown, the main body includes X, Y, and Z-axis drive mechanisms 2, 3, and 16 respectively arranged on the frame 1, and a placement head 6, a conveyor belt, and a feeding device. The driving mechanism of material belt 15 is made of needle bar 14 and transmission is connected to needle bar 14 as the electric, pneumatic (air pressure) or hydraulic driver 15a of the driver of material belt; Needle bar 14 is corresponding to material belt 15 on the feeding device The belt hole 15a is connected to the placement head, driven by an electric, pneumatic or hydraulic driver 14a, and can be moved forward, backward, left, right and up and down through the placement head.

[0020] The feeding device is a feeding frame 9 detachably connected to the frame 1 through a connecting piece, corresponding to several feed bins 12 respectively arranged on the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com