Method for operating a reciprocating piston engine and piston for a reciprocating piston engine

A reciprocating piston and engine technology, applied in the field of operating reciprocating piston engines and pistons for reciprocating piston engines, can solve the problems of optimized operation mode, impossibility, power loss, etc., achieve obvious power gain, and facilitate maintenance , Friction loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The main field of application of the invention is reciprocating piston engines designed as large engines, in particular large two-stroke diesel engines such as are used in the drive of ships. The basic structure and mode of operation of such devices are known per se and therefore do not need to be described in detail in the present case.

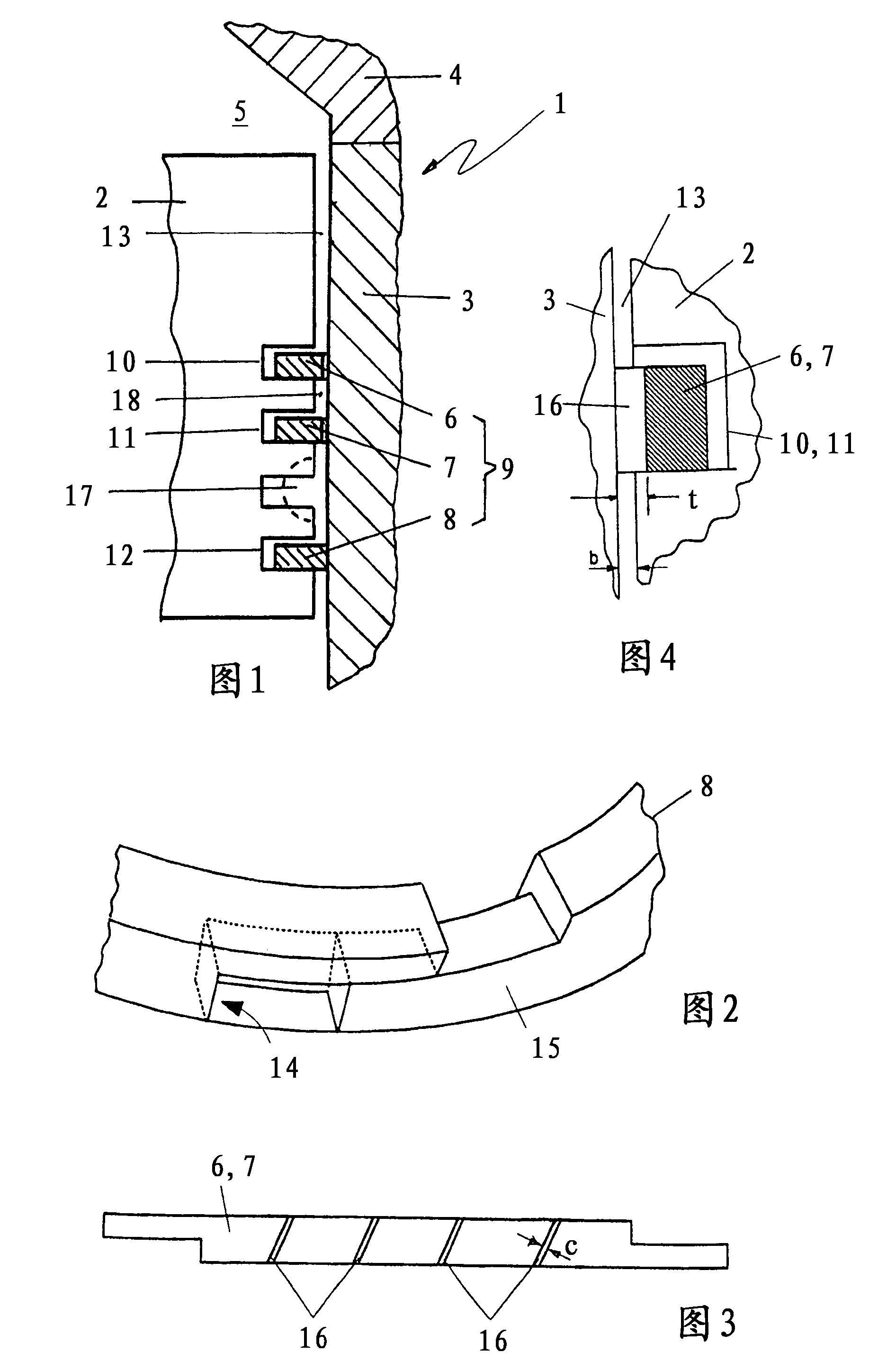

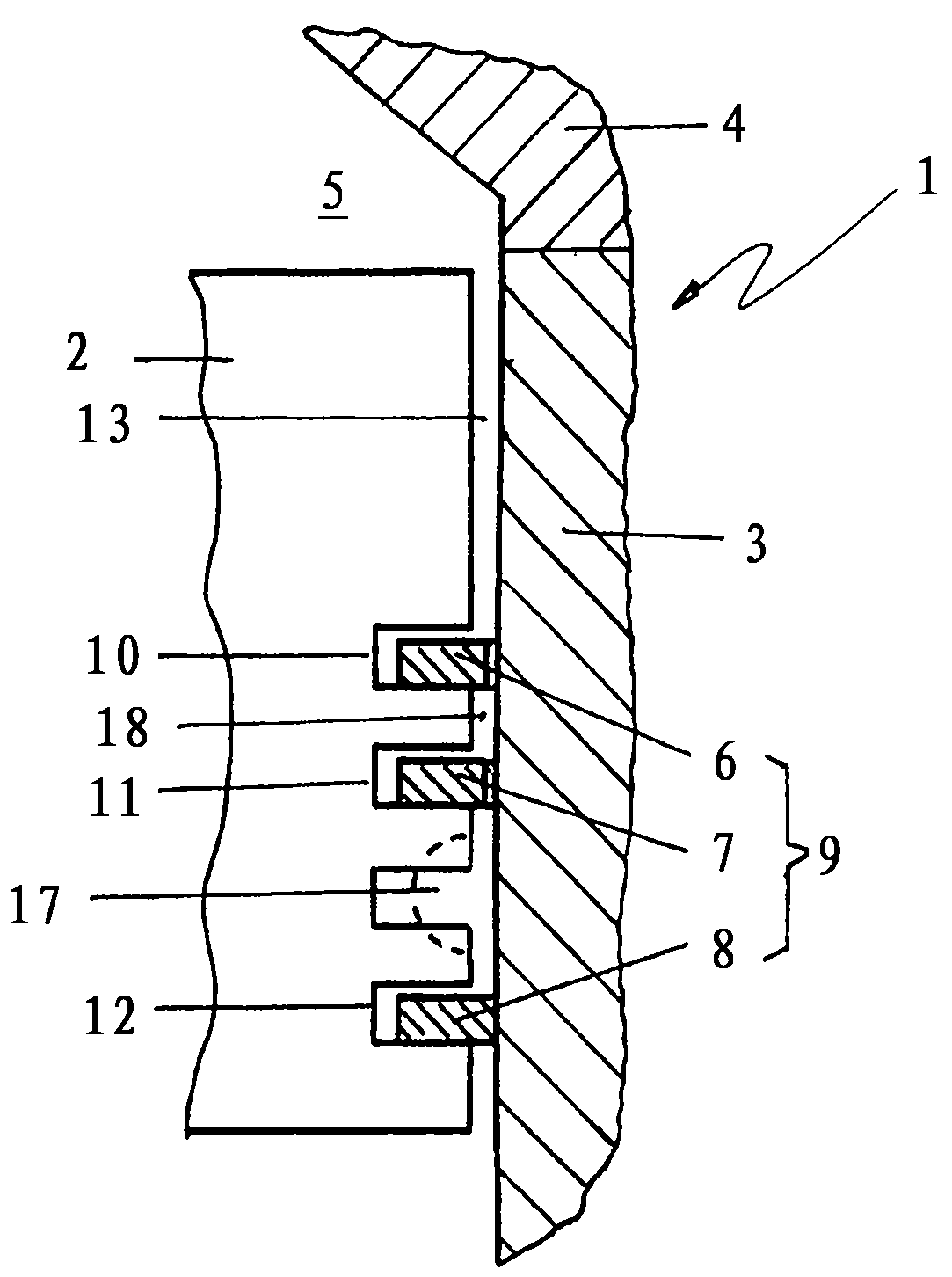

[0021] figure 1 The involved cylinder-piston assembly belongs to a two-stroke large diesel engine. The shown cylinder-piston assembly comprises a cylinder 1 and a piston 2 housed in the cylinder. The cylinder 1 comprises a surrounding cylinder liner 3 and a cylinder head 4 received thereon. A working chamber 5 is provided in the cylinder 1 , the lower boundary of which is formed by a vertically movable piston 2 guided in a cylinder liner 3 . During operation, the working chamber 5 is acted upon with a charge consisting mainly of air via an intake slot, not shown in detail, arranged in the lower region of the cylinder liner 3 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com