Method of wool surface modification and low temperature dyeing

A low-temperature dyeing and surface modification technology, applied in the field of textile printing and dyeing, can solve the problems that the processing capacity is limited by equipment, the biological enzymes are difficult to work, and the equipment requirements are high, so as to achieve energy saving and emission reduction of wool quality and wear performance, improve wool quality and The effect of wearing performance and improving dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Wool Variety: Pure Wool Loose Fiber.

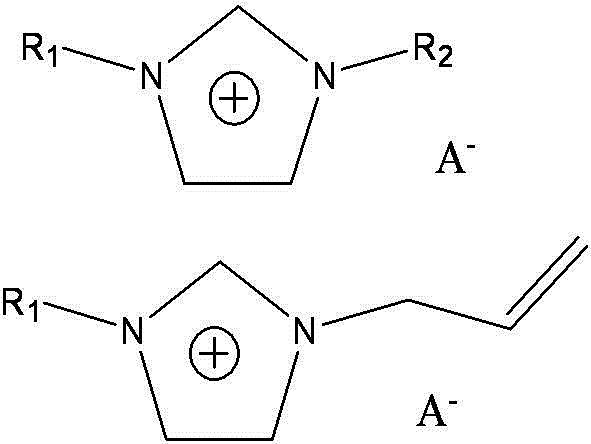

[0021] Ionic liquid treatment: the ionic liquid is selected from 1-ethyl-3-methylimidazolium bromide ([Emim]Br), the bath ratio is 1:30, the treatment temperature is 80°C, and the treatment time is 20mim. The attached ionic liquid is squeezed into the treated ionic liquid, and the treated fiber is washed with ethanol, finally washed with water, dried at 80°C, and the ethanol washing solution is preserved.

[0022] Acid dye dyeing: the fiber treated with ionic liquid is dyed with acid dye, the acid dye accounts for 1% by weight of the fiber, the sodium sulfate accounts for 10% by weight of the fiber, the bath ratio is 1:40, and the pH value is adjusted to 4.5-5.5, the dyeing temperature is 30°C, the temperature is raised to 60°C at 2°C / min, and the dyeing is kept for 80 minutes. After the dyeing is completed, it is soaped, washed, dehydrated, and dried.

[0023] Regeneration of ionic liquid: add deionized water to the treated ionic...

Embodiment 2

[0026] Wool Variety: Pure Wool Yarn.

[0027] Ionic liquid treatment: the ionic liquid is 1-butyl-3-methylimidazolium chloride ([Bmim]Cl), the liquor ratio is 1:10, the treatment temperature is 80°C, and the treatment time is 5mim. The attached ionic liquid is squeezed into the treated ionic liquid, and the treated fiber is washed with ethanol, finally washed with water, dried at 80°C, and the ethanol washing solution is preserved.

[0028] Acid dye dyeing: the wool yarn treated with ionic liquid is dyed with acid dye, the acid dye accounts for 1% of the fiber weight, the sodium sulfate accounts for 5% of the fiber weight, the bath ratio is 1:20, and the pH is adjusted with acetic acid The value is 4.5-5.5, the dyeing temperature is 40°C, the temperature is raised to 70°C at 2°C / min, and the dyeing is kept for 70 minutes. After the dyeing is completed, it is soaped, washed, dehydrated, and dried.

[0029] Other steps are consistent with embodiment 1.

Embodiment 3

[0031] Wool Variety: Pure wool fabric.

[0032] Ionic liquid treatment: the ionic liquid is 1-butyl-3-methylimidazole acetate ([Bmim]Ac), the bath ratio is 1:20, the treatment temperature is 70°C, and the treatment time is 8mim. After the treatment, the fiber The attached ionic liquid is rolled off into the treated ionic liquid, the treated fiber is washed with ethanol, finally washed with water, dried at 80°C, and the ethanol washing solution is preserved.

[0033] Dyeing with acid dye: dye the pure wool fabric treated with ionic liquid with acid dye, the acid dye accounts for 0.3% by weight of the fiber, the sodium sulfate accounts for 8% by weight of the fiber, the bath ratio is 1:30, and the pH is adjusted with acetic acid The value is 4.5-5.5, the dyeing temperature is 35°C, the temperature is raised to 80°C at 3°C / min, and the dyeing is kept for 60 minutes. After the dyeing is completed, it is soaped, washed, dehydrated, and dried.

[0034] Other steps are consistent wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com