Material-saving weft cutting device for rapier loom

A rapier loom and material-saving technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of defective cloth, high electricity costs, inconvenient installation and use, etc., and achieve precise weft pressing and adjustment convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

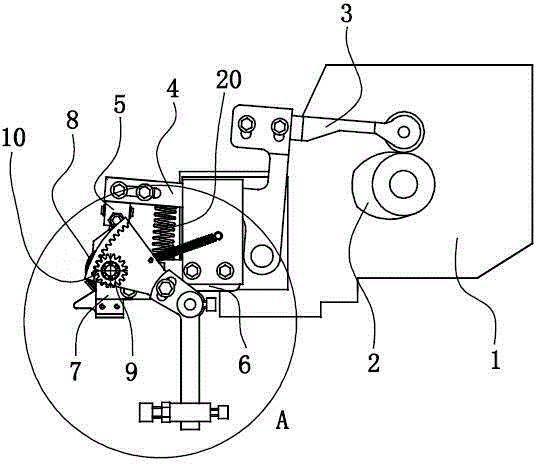

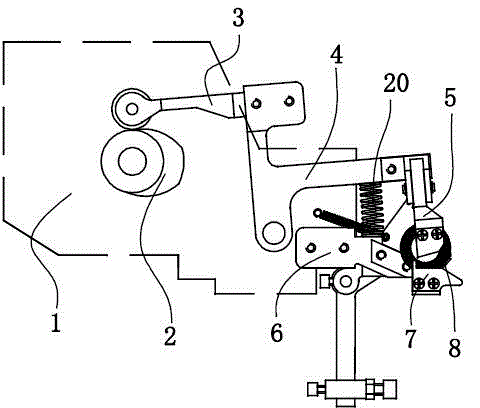

[0027] see figure 1 , a material-saving weft cutting device for a rapier loom, comprising an upper scissors assembly 5, a lower scissors assembly 7, a weft crimping mechanism arranged on the lower scissors assembly 7, and a transmission mechanism for driving the upper scissors assembly 5 to act. The lower scissors assembly 7 is fixedly connected to the transmission box 1 through the lower scissors fixing seat 6; the upper scissors assembly 5 is connected to the cam 2 on the transmission box 1 through the upper scissors rod 4 and the linkage rod 3, and is arranged on the upper The scissors compression spring 20 between the scissors bar 4 and the lower scissors holder 6 cooperates with the lower scissors assembly 7 to perform the opening and closing shearing action.

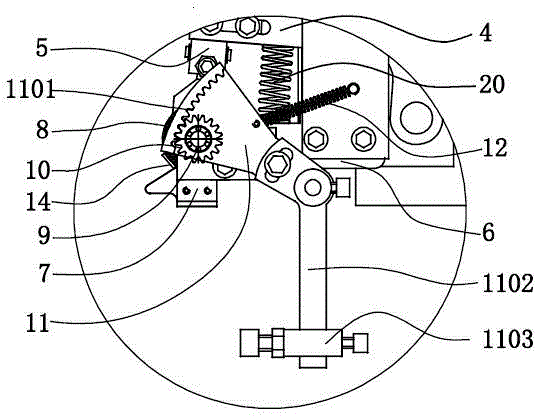

[0028] see figure 2 , the weft thread rolling mechanism is arranged on the lower scissors fixing seat 6 of the lower scissor assembly 7 through a weft pressing frame, which includes a weft pressing wheel 8, and a...

Embodiment 2

[0035] In this embodiment, except that the driving mode of the weft pressing wheel 8 is different, other structures and working principles of weft pressing are the same as those in the embodiment.

[0036] see Figure 7 - Figure 9 , In this embodiment, the driven wheel 10 is driven by a belt 13, and its driving wheel 11 is arranged on the shaft of the cam 2. Driving the weft pressing wheel 8 to rotate through the belt 13 can reduce the impact noise between the dragon 21 and the hammer 1103 when the first embodiment is working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com