Steel for wheels of rapid transit railway vehicles

A high-speed railway and wheel technology, applied in the field of high-speed railway steel, can solve the problems of not being officially used and staying, and achieve the effects of delaying initiation and expansion, improving safety, and improving fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

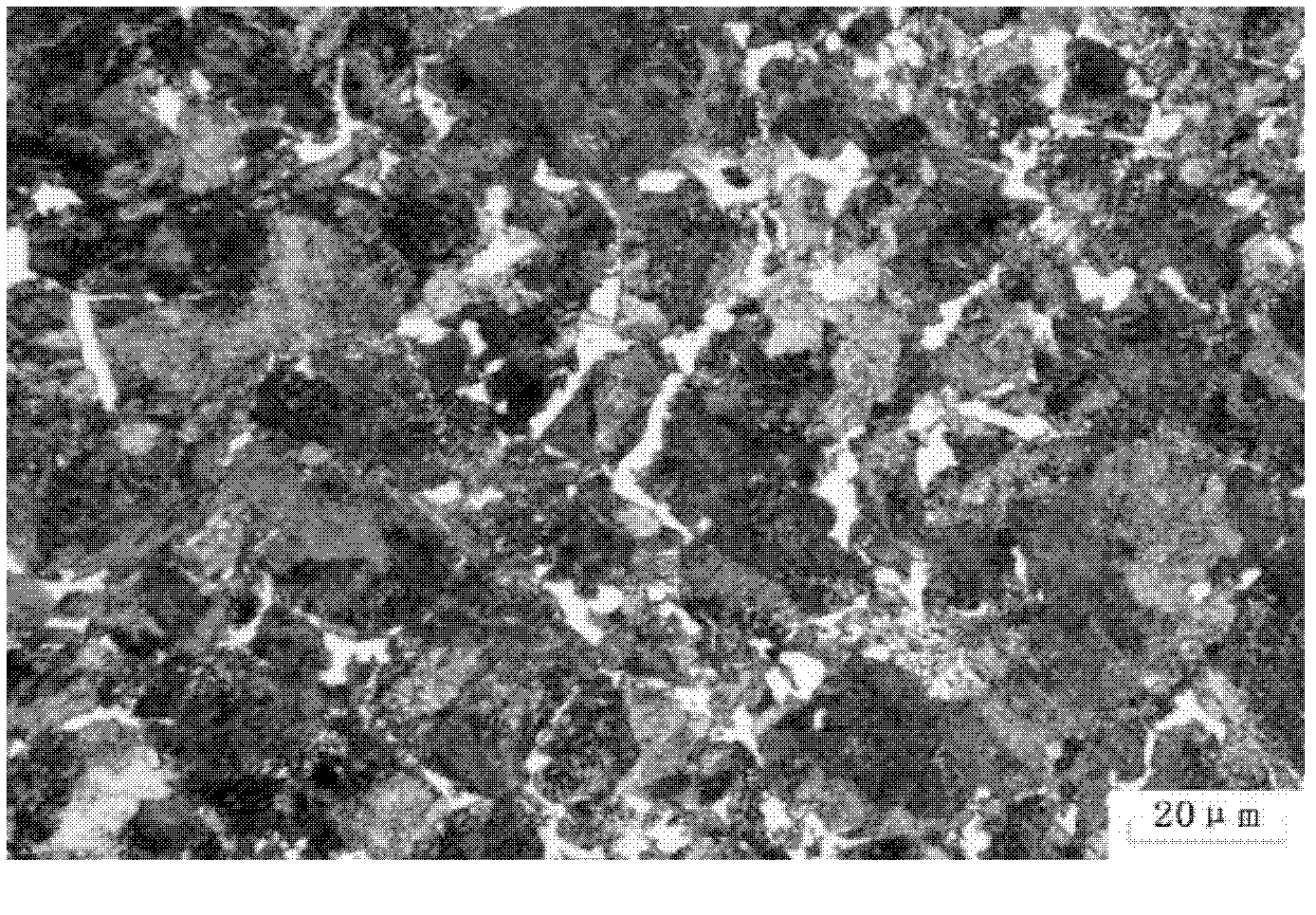

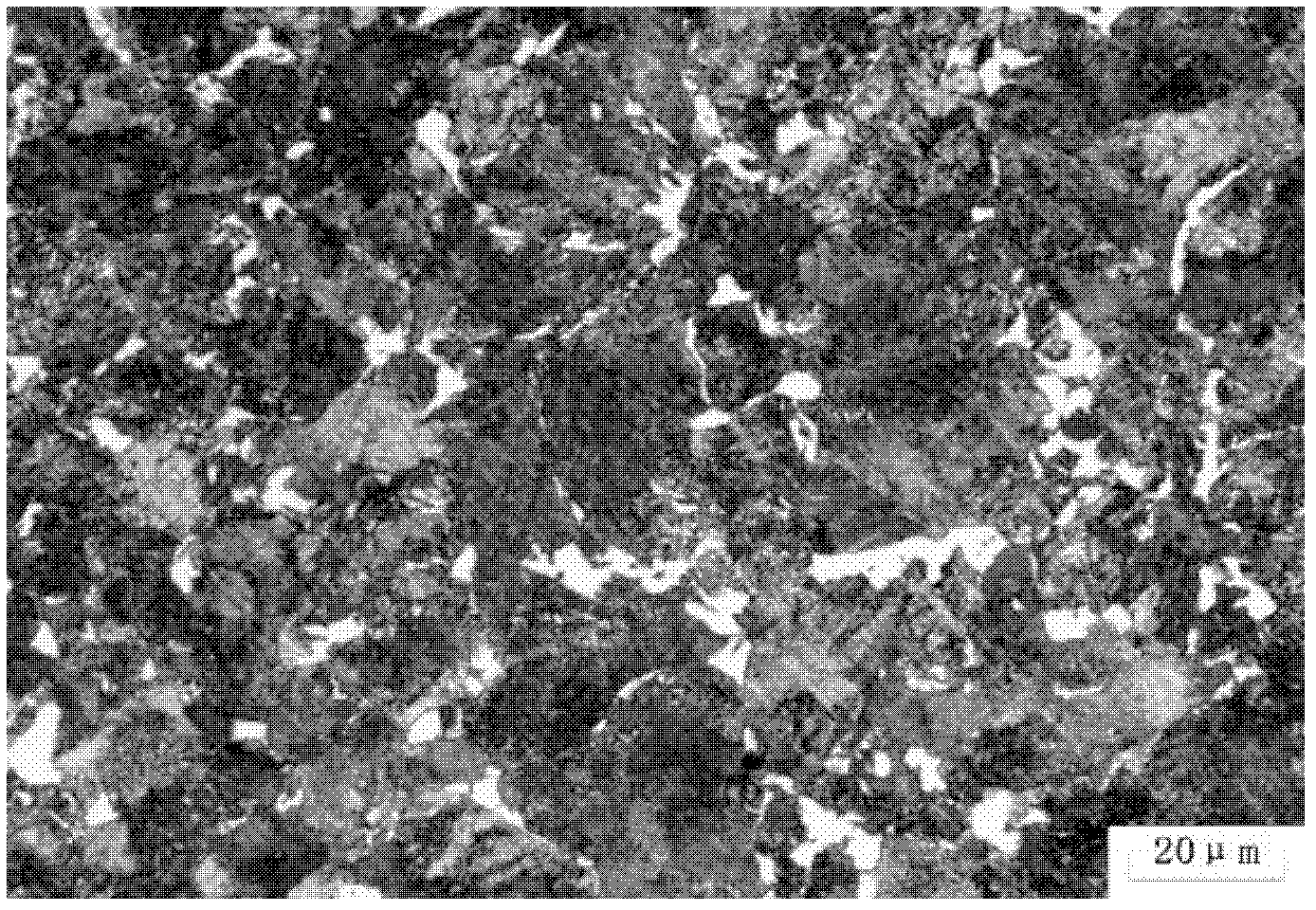

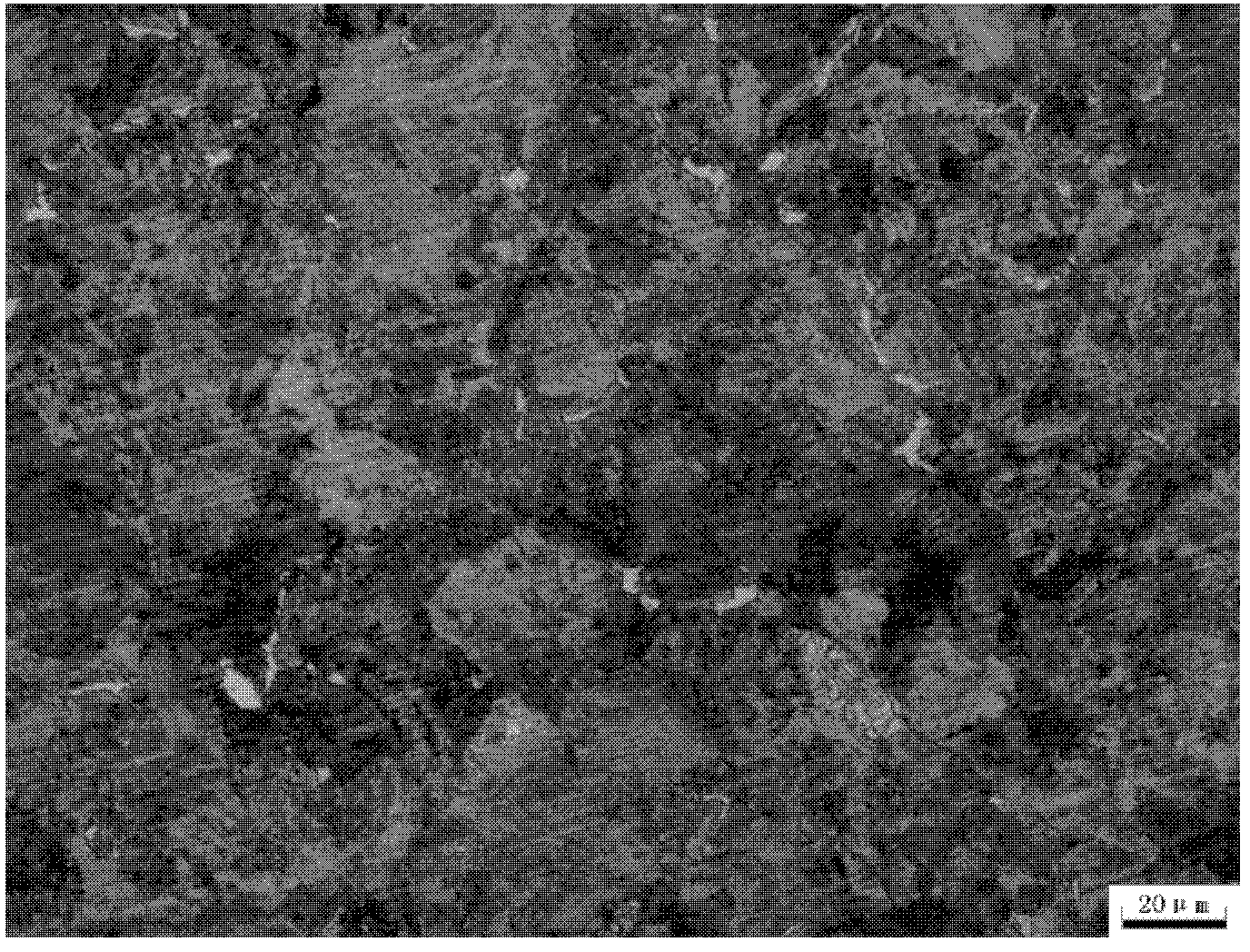

Image

Examples

Embodiment 1

[0031] The chemical composition in mass percent is: C: 0.55%, Si: 0.29%, Mn: 0.72%, Cr: 0.18%, P: 0.007%, S: 0.006%, Al: 0.022%, O: 0.0010%, Ca : 0.0005%, the balance is Fe; the inclusions are modified by Ca during the smelting process. Wheels for railway vehicles are manufactured using the steel materials described above.

Embodiment 2

[0035]A steel material, including by mass: C: 0.66%, Si: 0.29%, Mn: 0.82%, Cr: 0.09%, P: 0.015%, S: 0.015%, Al: 0.038%, O: 0.0006%, Ca: 0.0029%, the balance being Fe; the steel material undergoes Ca modification treatment on inclusions during the smelting process. Wheels for high-speed railway vehicles are produced using the above-mentioned steel materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com