Resin mold used for molding glass plate by pressing outside furnace

A technology for resin molds and glass plates, applied in the field of press molding molds, can solve the problems of long development and production cycle of metal molds and high mold production costs, achieve long-term continuous and stable production, reduce production costs, and improve the effect of thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be further described below in conjunction with the accompanying drawings.

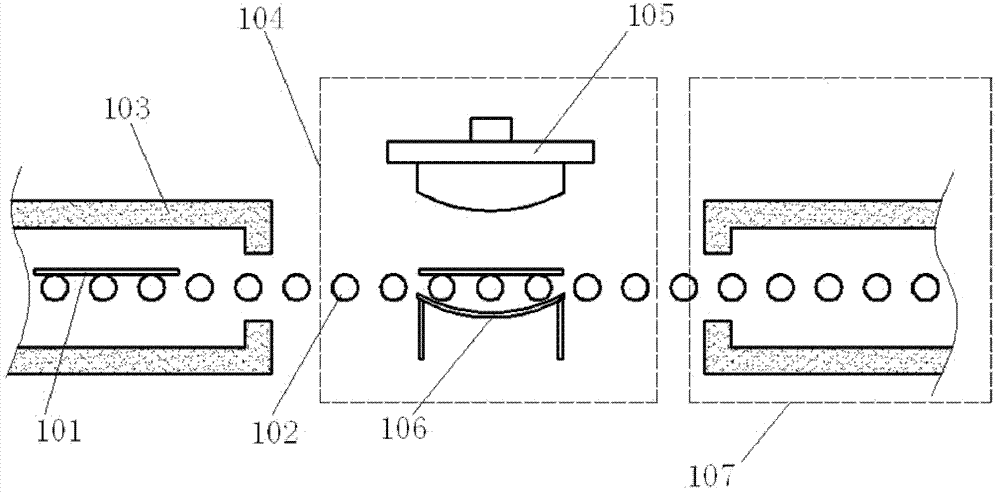

[0026] Such as figure 1 As shown, in the production process of pressing outside the glass furnace, a heating furnace 103 is installed on the production line. The heating furnace is mainly used to heat and soften the glass plate to prepare for the next step of bending. The glass plate 101 is transported through the horizontal conveying roller table 102. Overheating furnace 103.

[0027] After being heated by the heating furnace 103, the glass plate 101 reaches the softening temperature and is transported into the forming area 104 through the horizontal conveying roller table 102. The forming area 104 is provided with a pressing punch 105 and a pressing die 106. When the glass plate 101 approaches the pressing die When 106 is directly above, the pressing die 106 rises rapidly and holds up the softened glass plate 101 and presses against the pressing punch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com