A punching machine mechanism with magnetic drive

A technology of magnetic transmission and punching machine, applied in the field of punching machinery, can solve the problems of low frequency of punching, low production efficiency, complex mechanism, etc., and achieve the effects of low cost, high production efficiency and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

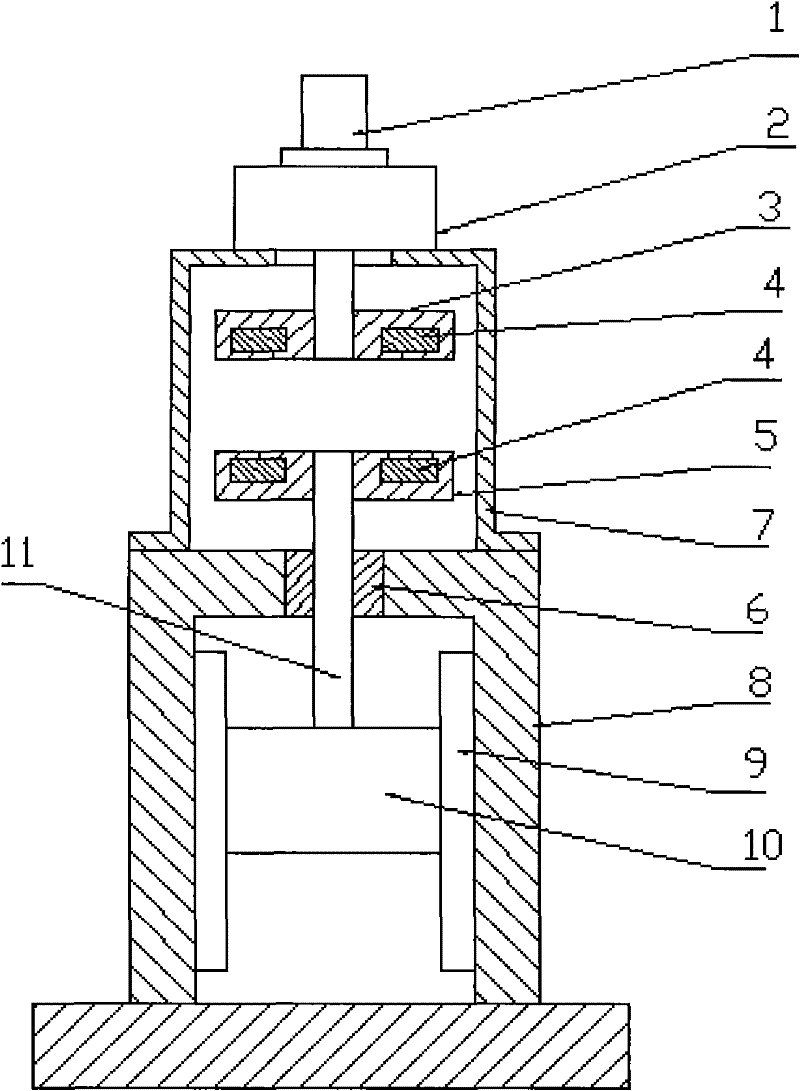

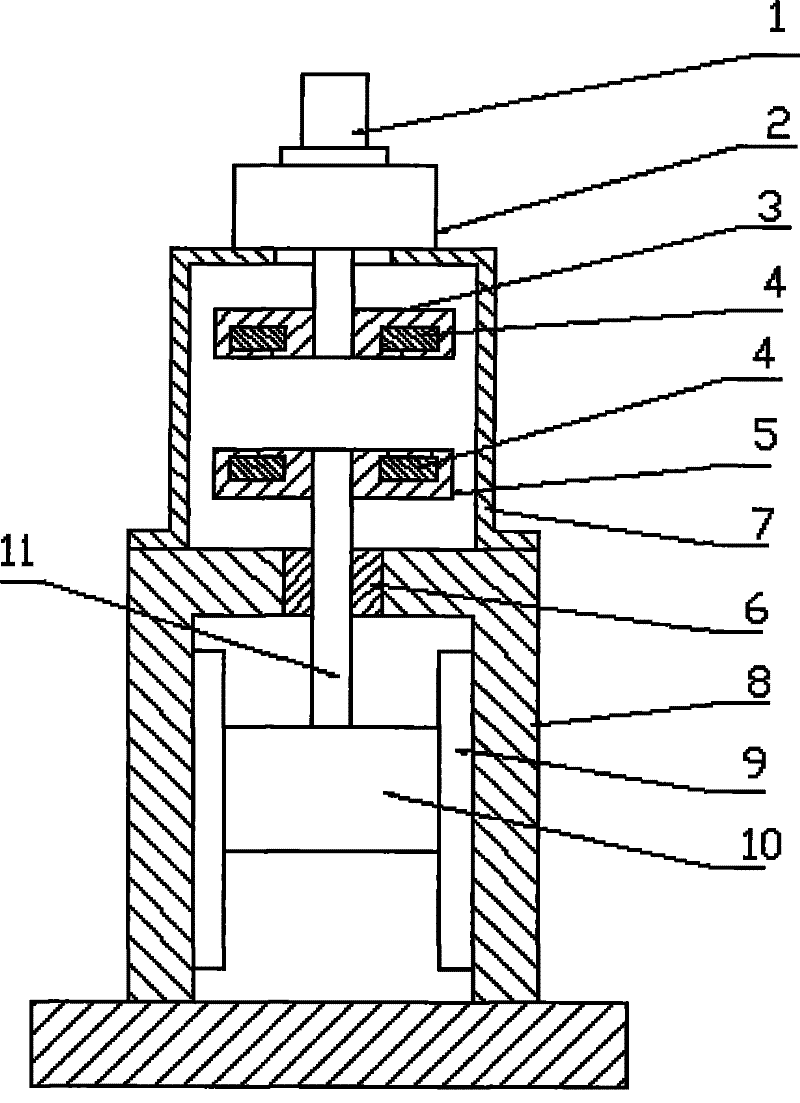

[0009] The stamping machine mechanism has a slider (10), the slider (10) is installed on the fuselage (8) through the guide rail (9), and a sliding bearing (6) is installed on the top of the fuselage (8), and the drive shaft (11) Pass through the sliding bearing (6) and connect with the slider (10) through the bottom of the drive shaft (11). A drive disc (5) is installed on the top of the drive shaft (11), and the polarity of the magnet (4) On the contrary, it is symmetrically embedded in the drive disc (5); a drum support (7) is installed on the top of the fuselage (8), and the center line of the drum support (7) is concentric with the center line of the drive disc (5). The rotating disk (3) is installed on the output shaft of the reducer (2), and the magnet (4) is inlaid in the rotating disk (3) with opposite polarity and symmetrically; a reduction box is installed on the upper part of the drum support (7) (2), the frequency conversion motor (1) is connected with the reducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com