Plastic softener

A softening machine and plastic technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of operator safety threats and low efficiency, and achieve the effect of improving softening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

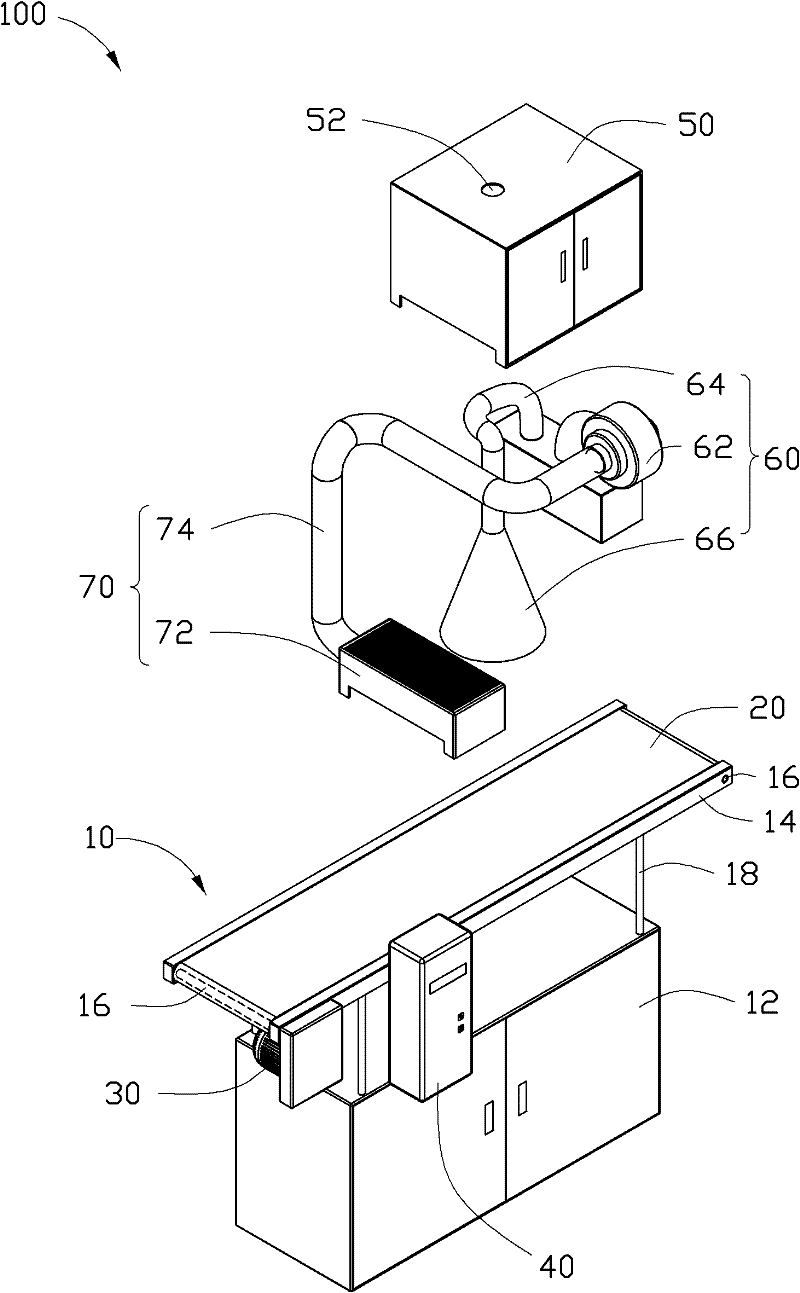

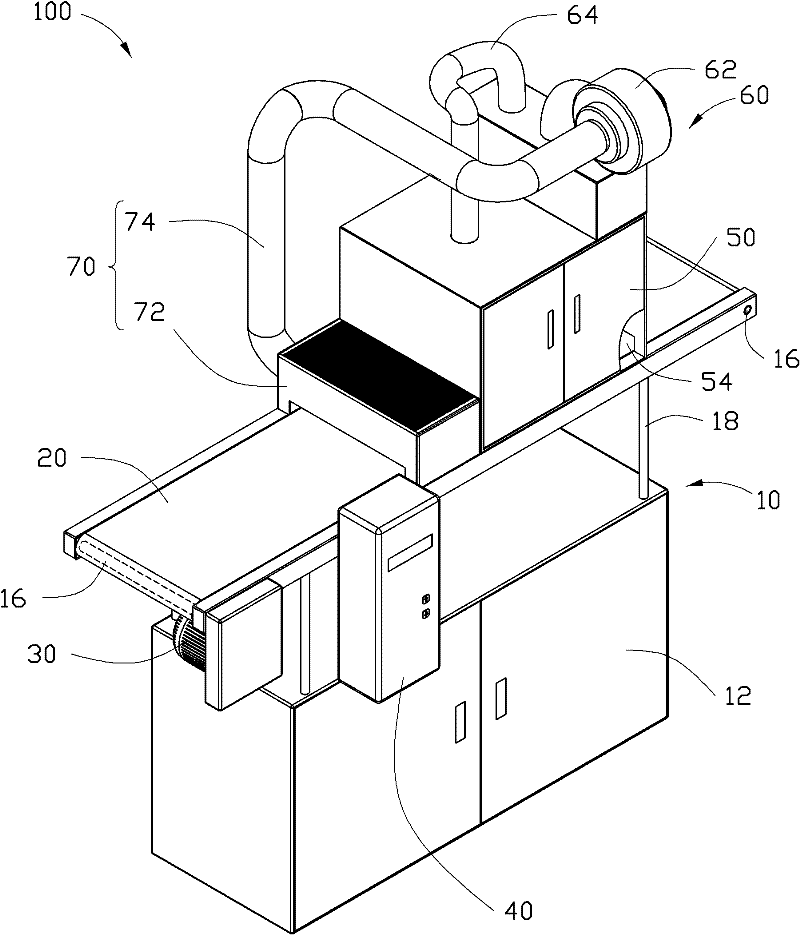

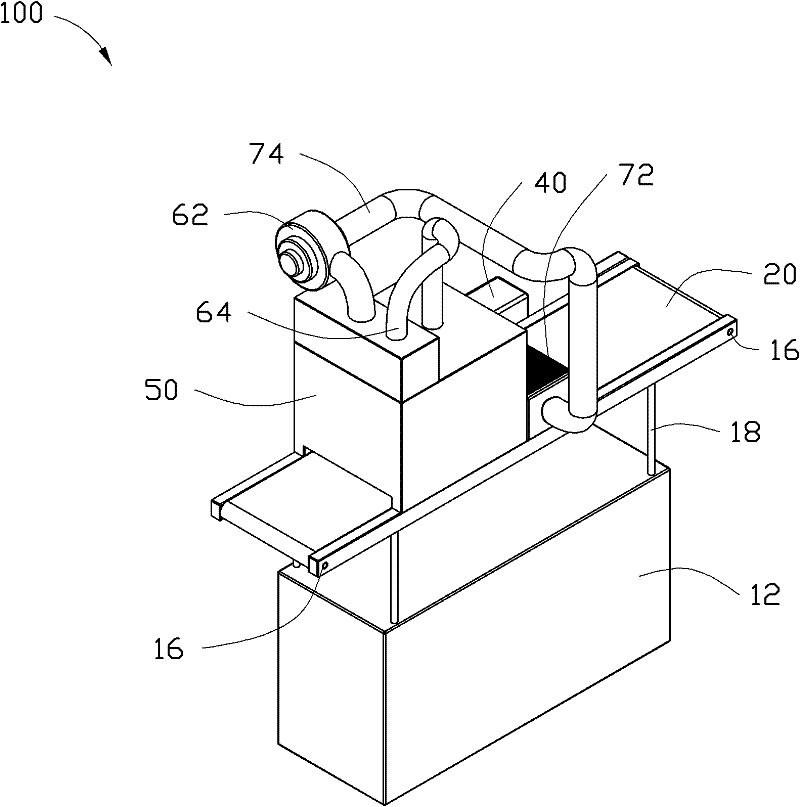

[0028] see figure 1 , The plastic softening machine 100 includes a frame 10 , a conveyor belt 20 , a motor 30 , a control unit 40 , a heating box 50 , a heating component 60 and a heat recovery component 70 . The conveyor belt 20 , the motor 30 , the control unit 40 , the heating box 50 , the heating assembly 60 and the hot gas recovery assembly 70 are all mounted on the frame 10 .

[0029] The frame 10 includes a cabinet 12 , two transmission frames 14 arranged in parallel, two rotating shafts 16 arranged between the transmission frames 14 , and four brackets 18 connecting the cabinet 12 and the transmission frames 14 . One of the rotating shafts 16 is connected with a motor 30 to provide rotational power to the conveyor belt 20 . Moreover, two brackets 18 are provided between each transmission rack 14 and the cabinet 12 , and the brackets 18 are used to support the transmission rack 14 on the cabinet 12 .

[0030] The conveyor belt 20 is a ring-shaped belt body, the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com