Two-stage flotation process of coal slime with particle size less than 0.5mm

A flotation and particle size technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of high ash content in flotation clean coal, affecting the separation technical indicators of coal preparation plants and closed-circuit washing water circulation, etc. Achieve the effect of reducing moisture, eliminating vicious circle and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

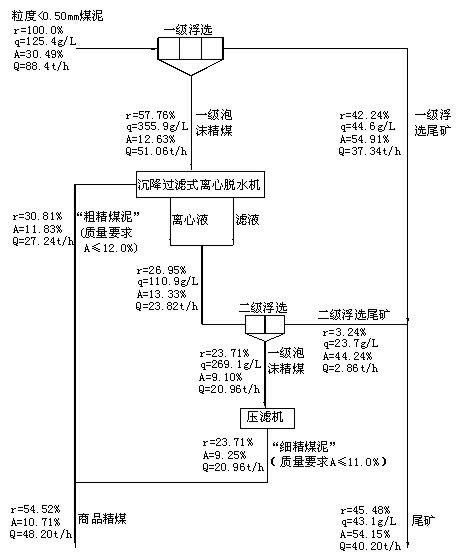

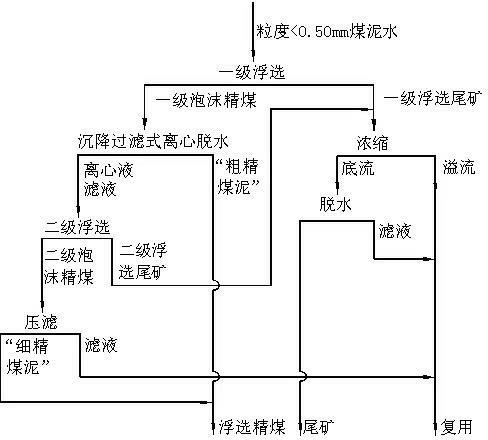

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0013] See attached figure 1 , the present invention discloses a two-stage flotation process for coal slime with a particle size of less than 0.5mm. The secondary flotation of fine coal slime whose particle size is mainly less than 0.045mm, the two-stage flotation process described here is carried out according to the following steps:

[0014] ① Coal slime with a particle size of less than 0.5 mm enters the first-stage flotation, and the tailings of the first-stage flotation enter the tailings treatment process; the foamed clean coal of the first-stage flotation is dehydrated by a sedimentation filter centrifuge, and recovered with a particle size greater than 0.045 Coarse fine slime mainly in mm.

[0015] ② The centrate and filtrate after dehydration by the sedimentation filter centrifuge enter the secondary flotation, wherein the tailings of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com