Molten metal processing equipment, molten metal processing method, and molten metal conveying line using the same

A technology for molten metal and processing equipment, which is applied in the field of graphite spheroidization and slag removal, can solve the problems of huge molten metal, increased cost, prolonged molten metal circulation time, etc., and achieves the effect of realizing cycle time and compact equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

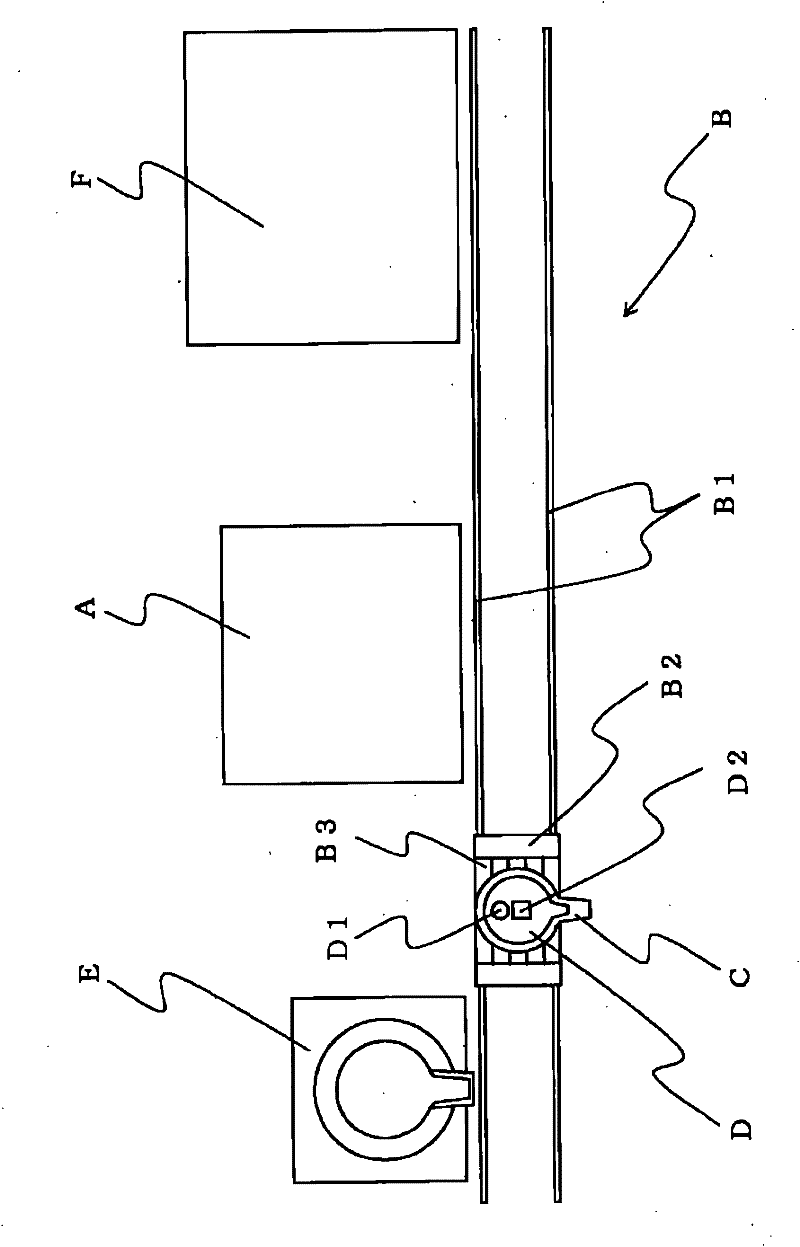

[0044] Next, Figure 6 The second embodiment of the molten metal transfer line using the molten metal processing facility of the present invention is shown. Figure 6 The molten metal delivery line shown is composed of a melting device E having a melting furnace for melting materials such as iron or a holding furnace for holding the molten molten metal, and receiving the molten metal To ladle C; Molten metal treatment equipment A, this molten metal treatment equipment A carries out graphite spheroidization process to the molten metal in ladle C, and slag is removed; Casting equipment F, this pouring equipment F has multiple molten metal The automatic pouring device F1 that pours into the mold; the first rail B1a, which is adjacent to the melting equipment; the first trolley B2a, which is loaded with a ladle and travels on the first rail B1a ; The first roller conveyor B3a, the first roller conveyor B3a is orthogonal to the first track B1a and receives the ladle C from the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com