A sanding method for diamond wire saw

A diamond and wire saw technology, which is applied to the sanding field of diamond wire saws, can solve the problems of easy deviation and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Preparation of diamond electroplating solution:

[0025] Weigh 10,000 grams of nickel sulfate, 10,000 grams of nickel chloride, 1,000 grams of cobalt sulfate, and 5,000 grams of boric acid. The liquid reaches 100L, and 2000 grams of diamonds are added thereto, stirred and heated to 45 degrees to complete the preparation of the electroplating liquid. Each liter of prepared electroplating solution contains: 20 grams of diamond, 100 grams of NiSO 4 , 100 grams of NiCl 2 , 10 g CoSO 4 , 50 g H 2 BO 3 .

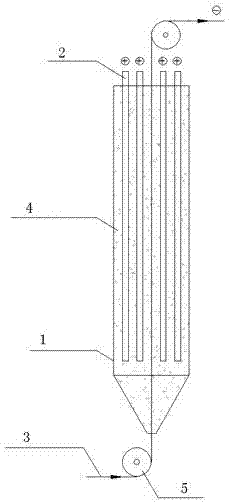

[0026] 2) Place the electroplating solution 4 in the sand loading tower 1 made of PVC, and keep the temperature of the electroplating solution 4 at 45 degrees during the sand loading process. In this embodiment, the upper sand tower 1 is cylindrical in shape with an inner diameter of 100 mm, placed vertically, and four Ni anodes 2 are evenly placed on the inner wall thereof.

[0027] 3) Insert the bare wire 3 with a diameter of 0.25mm from the bottom of the up...

Embodiment 2

[0030] 2) Preparation of diamond electroplating solution:

[0031] Weigh 24,000 grams of nickel sulfate, 4,000 grams of nickel chloride, 4,000 grams of cobalt sulfate, and 6,000 grams of boric acid. When the liquid reaches 100L, add 1000 grams of diamond to it, stir and heat to 42 degrees to complete the preparation of the electroplating solution. Each liter of prepared electroplating solution contains: 10 grams of diamond, 240 grams of NiSO 4 , 40 grams of NiCl 2 , 40 g CoSO 4 , 60 g H 2 BO 3 .

[0032] 2) Place the electroplating solution 4 in the sand loading tower 1 made of PVC, and keep the temperature of the electroplating solution 4 at 45 degrees during the sand loading process. In this embodiment, the upper sand tower 1 is in the shape of a regular octagon, and the distance between the two sides of the inner cavity is 100mm, and it is placed vertically, and 8 Ni anodes 2 are evenly placed on the inner wall.

[0033] 3) Insert the metal bare wire 3 with a diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com