Mechanism for transferring welding stations of frame parts of motorcycle

A component welding and transmission mechanism technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of welding arc light can not be effectively blocked, handling waste, increased manufacturing costs, etc., to protect physical and mental health, ensure Physical quality, the effect of preventing collision deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

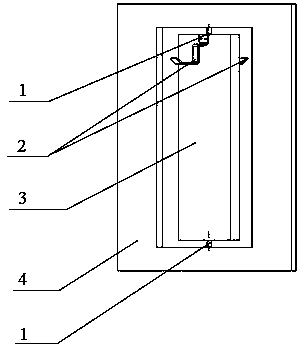

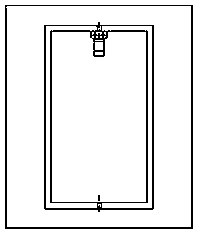

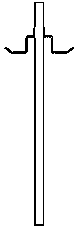

[0016] In specific implementation, such as Figure 1 to Figure 3 As shown, a welding station transmission mechanism for motorcycle frame parts, a partition wall 4 is set between two adjacent welding stations, a door frame is provided on the partition wall 4, and a door frame is matchedly installed in the door frame. Rotating plate 3, the upper and lower ends of the rotating plate are rotatably installed on the door frame by the rotating shaft 1 vertically arranged in the middle part of the upper and lower ends of the rotating plate. Both sides of the rotating plate 3 are provided with hooks 2 for hanging motorcycle frame parts.

[0017] During specific implementation, the welding station is located between individual welding chambers, and the partition wall 4 is a steel wall. Both the door frame and the rotating plate 3 are matched r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com