A kind of energy-saving furnace with cyclone generating device

A technology of generating device and energy-saving furnace, which is applied to household stoves/stoves, household cooking utensils, combustion methods, etc., can solve the problems of short delivery time, gas loss, insufficient mixing and combustion, and achieve longer mixing time and mixing path. , the effect of long burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

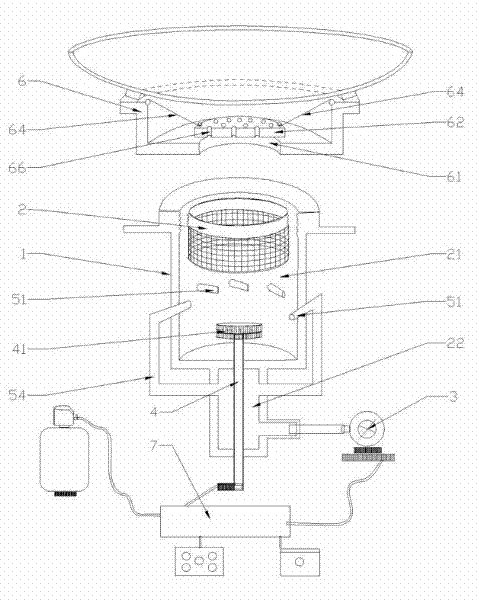

[0022] Such as figure 1As shown, the present invention includes a furnace chamber 6, a furnace chamber 1, a reticulated furnace core 2, and a blower fan 3. The furnace chamber 1 is made of a high-temperature-resistant material, and the furnace chamber 1 is connected to the bottom of the furnace chamber 6. The furnace chamber 1 The upper part is a gas and air rotary mixing zone 21, and the lower part is an air intake zone 22. The mesh furnace core 2 is arranged above the gas and air rotary mixing zone 21 in the furnace chamber 1, and the fan 3 and the The air intake area 22 of the furnace cavity 1 communicates, and the fan 3 provides the air required for combustion. The furnace cavity 1 is provided with a gas channel 4, and the end of the gas channel 4 is connected to the gas supply device outside the energy-saving furnace ( Such as a gas bottle), the gas channel 4 extends into the gas and air rotary mixing zone 21 to input the gas required for combustion. The present invention...

Embodiment 2

[0024] Such as figure 2 As shown, in this embodiment, the cyclone generating device includes a vertical straight plate 53, and several of the air outlet nozzles 51 are distributed on the side wall of the vertical straight plate 53 along the circumference, and the air intake area 22 passes through the The air outlet nozzle 51 communicates with the gas and air rotary mixing area 21 .

[0025] In this embodiment, on the basis of the cyclone generating device, the structure of the cover plate 62 is added. In the implementation, the pot is adapted to the upper part of the furnace 6, and a combustion through hole 61 is opened at the bottom of the furnace 6. A cover plate 62 made of a high-temperature-resistant material is arranged above the combustion through hole 61, and a gap is formed between the cover plate 62 and the bottom of the furnace 6 through a bracket device, and the furnace chamber 1 is connected to the furnace chamber 1 through the gap. The furnace 6 communicates, th...

Embodiment 3

[0028] Such as image 3 As shown, in this embodiment, the cyclone generating device includes a plurality of ventilation pipes 54, one end of the ventilation pipes 54 communicates with the air intake area 22, and the other end is an air outlet nozzle 51, and the air outlet nozzle 51 is inserted obliquely The outer wall of the furnace cavity 1 extends into the air and gas rotary mixing zone 21 , and the air intake zone 22 communicates with the gas and air rotary mixing zone 21 through the air outlet nozzle 51 of the air pipe 54 .

[0029] In this embodiment, the cover plate 62 is provided with several through holes 51, and the flame in the first combustion chamber can directly enter the first combustion chamber through the through holes 66 of the cover plate 62 to heat the pot. . The diameter of the through hole 66 is 4mm˜40mm.

[0030] In this embodiment, the support device is a fixed stay rope 64, one end of the fixed stay rope 64 is fixedly connected to the cover plate 62, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com