Supercritical Boiler Superheater Tube Panel Fixing Device and Method

A supercritical boiler and superheater tube technology, applied in the field of boilers, can solve problems such as tube panel deformation, and achieve the effect of solving deformation and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

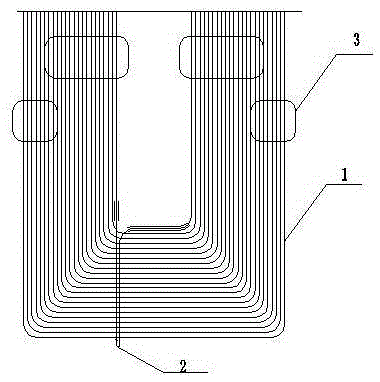

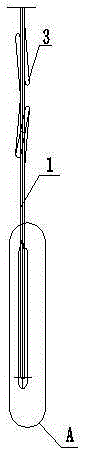

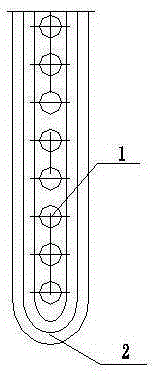

[0023] A supercritical boiler superheater tube panel fixing device, its composition includes: the tube 1 forms a tube panel, a circle of winding tubes 3 is added near the lower tube panel, and at the same time, the bottom of the tube in the inner ring of the tube panel is pulled out to form a The clamping tube 2 clamps the tube panel.

Embodiment 2

[0025] A method for fixing a supercritical boiler superheater tube panel. A group of tubes are arranged and installed in sequence to form a tube panel. A circle of winding tubes is added near the lower tube panel, and at the same time, the bottom of the tubes in the inner circle of the tube panel is pulled out to form a tube panel. The clamping tube clamps the tube screen so that the tube can expand freely and prevent the tube from being deformed and out of the queue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com