A kind of bio-organic fertilizer of edible mushroom residue and preparation method thereof

A bio-organic fertilizer and edible fungus technology, applied in application, fertilization device, fertilizer mixture, etc., can solve the problems of resource waste, environmental pollution, burning seedlings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

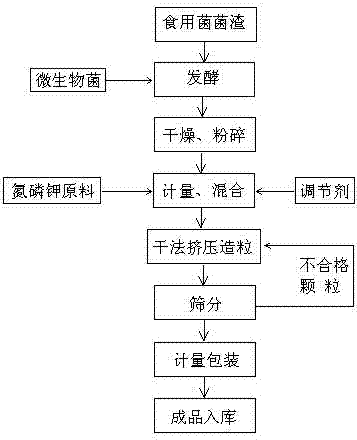

Method used

Image

Examples

Embodiment 1

[0025] A bio-organic fertilizer with edible fungus residue, mainly composed of the following raw materials in weight percentage: 75% edible fungus residue, 10% urea, 8% monoammonium phosphate, 5.3% potassium sulfate, 1.5% microbial bacteria, and 0.2% regulator %. The regulator is a mixture composed of tetramethylglutaric acid, DA-6 and sodium 5-nitroguaiacol, and the weight ratio of the three is 1:3:1.

[0026]

Embodiment 2

[0028] A bio-organic fertilizer with edible fungus residue, mainly composed of the following raw materials in weight percentage: 80% edible fungus residue, 8% urea, 6% monoammonium phosphate, 4.7% potassium sulfate, 1% microbial bacteria, and 0.3% regulator %. The regulator is a mixture composed of tetramethylglutaric acid, DA-6 and sodium 5-nitroguaiacol, and the weight ratio of the three is 1:2:2.

[0029] The preparation method of the edible fungus slag bio-organic fertilizer described in the above-mentioned embodiments comprises the following steps: a. fermentation of the slag of the edible fungus: mechanically turning the slag of the edible fungus and the microbial bacteria that have been crushed and dried, and then stacking and fermenting, so that the fermented The fermentation temperature of the material rises to 40-45°C within 24 hours, and the temperature rises to 58-63°C within 48 hours, and completes decomposing and dehydration within 7 days; b. After the fermented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com