A car roof grabbing and conveying device

A technology of conveying device and car roof, which is applied in the field of automobile manufacturing, can solve the problems of difficult operation, large number of transporters, and high roof setting, so as to achieve the effects of easy maintenance and operation, lightening labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

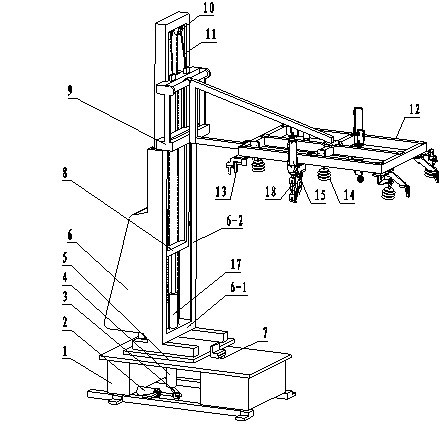

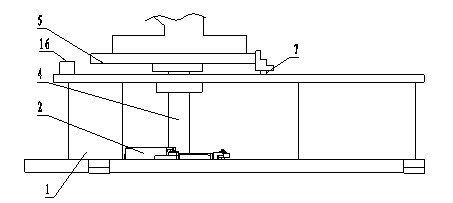

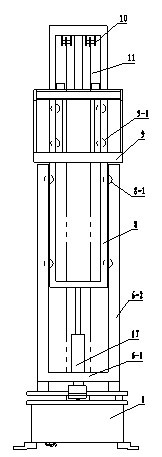

[0019] see figure 1 , figure 2 , the present invention consists of a base 1, an indexing mechanism, a lifting mechanism and a grabbing mechanism. The base is the bearing part of the whole device, which is fixed with the ground by anchor bolts, so that the whole device can smoothly complete various actions. The indexing mechanism completes the indexing action of the device, and it includes an indexing cylinder 2, a connecting rod 3, a rotating shaft 4 and a rotating base 5. The indexing cylinder, connecting rod, and rotating shaft are installed in the hollow space of the base. The indexing cylinder is hinged to the base. One end of the connecting rod is hinged to the indexing cylinder rod, and the other end is fixed to the rotating shaft. The rotating shaft is fixed and rotated through the flange. The base, the rotating base is arranged on the upper part of the base, and the lifting mechanism is located on the rotating base. The lower part of the rotating base 5 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com