Novel ignition temperature measuring device for experiment

A temperature measuring device and experimental technology, applied in the direction of measuring devices, electric devices, combustion and ignition, etc., can solve the problems of generating a large amount of smoke, affecting, affecting the shape of the flame and the flame structure, etc., to achieve good conductivity and influence small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

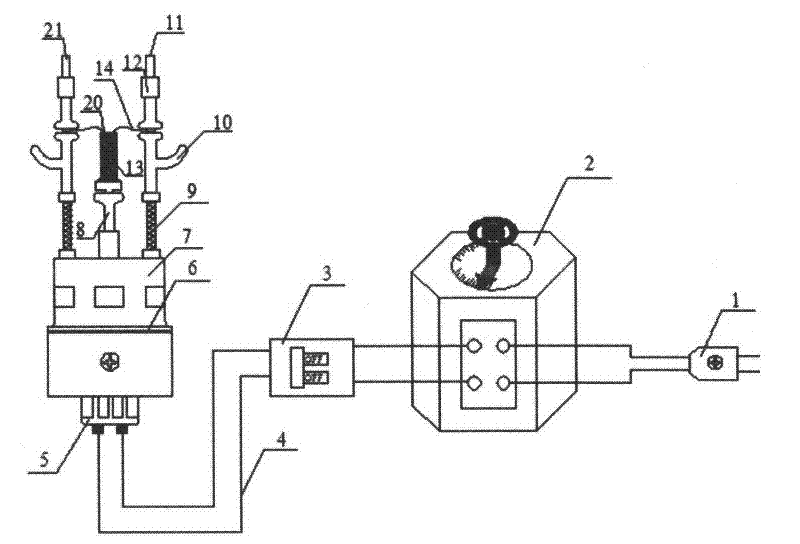

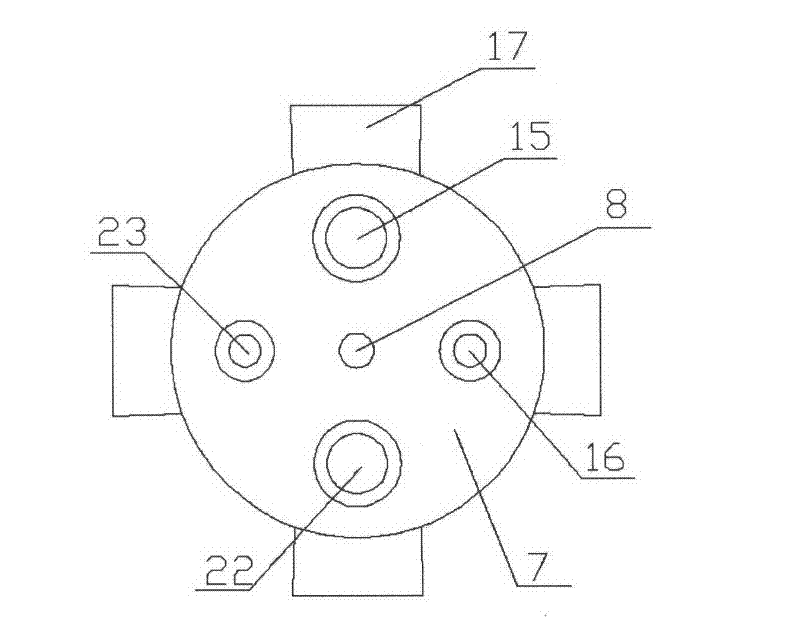

[0045] A new type of ignition temperature measuring device for experiments, comprising an ignition wire 14, an ignition power supply 5, and an ignition platform 7. The ignition platform 7 made of high-voltage and high-temperature-resistant stainless steel is provided with a first point of polytetrafluoroethylene insulating material Fire hole 15 and the second ignition hole 22; Ignition temperature measuring cylinder 13 is placed on the support 8 above the central part of the ignition platform 7; Ignition wire 14 is placed above the ignition temperature measuring cylinder 13; bracket 10, clip spring 9, tight The first ignition column 11 and the second ignition column 21 of the fixed rotary piece 12 are fixed on the ignition platform 7, and are respectively connected with the ignition power supply 5 through the first ignition hole 15 and the second ignition hole 22 of the ignition platform 7; 5 is to be connected by wire 4 by plug 1, power-off protector 3, contact voltage regulat...

Embodiment 2

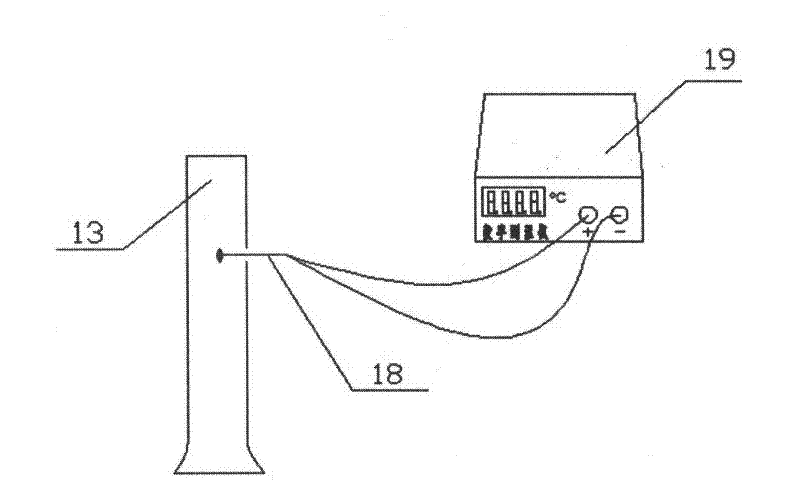

[0048] A new type of ignition temperature measuring device for experiments, comprising an ignition wire 14, an ignition power supply 5, and an ignition platform 7. The ignition platform 7 made of high-voltage and high-temperature-resistant stainless steel is provided with a first point of polytetrafluoroethylene insulating material Fire hole 15 , second ignition hole 22 , first temperature measurement hole 16 and second temperature measurement hole 23 . Ignition and temperature measuring tube 13 is placed on the bracket 8 above the center of the ignition platform 7; ignition wire 14 is placed above the ignition and temperature measuring tube 13; The second ignition column 21 is fixed on the ignition platform 7, and is connected with the ignition power supply 5 by the first ignition hole 15 and the second ignition hole 22 of the ignition platform 7 respectively; , The contact voltage regulator 2 is connected through a wire 4 . There is a small hole on the ignition temperature ...

Embodiment 3

[0051] A new type of ignition temperature measuring device for experiments, comprising an ignition wire 14, an ignition power supply 5, and an ignition platform 7. The ignition platform 7 made of high-voltage and high-temperature-resistant stainless steel is provided with a first point of polytetrafluoroethylene insulating material Fire hole 15 , second ignition hole 22 , first temperature measurement hole 16 and second temperature measurement hole 23 . Ignition and temperature measuring tube 13 is placed on the bracket 8 above the center of the ignition platform 7; ignition wire 14 is placed above the ignition and temperature measuring tube 13; The second ignition column 21 is fixed on the ignition platform 7, and is connected with the ignition power supply 5 by the first ignition hole 15 and the second ignition hole 22 of the ignition platform 7 respectively; , The contact voltage regulator 2 is connected through a wire 4 . There is a small hole on the ignition temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com