Arrangement structure for outlet pipeline of screen type superheater

A panel superheater and outlet pipe technology, which is applied in steam superheating, lighting and heating equipment, steam generation, etc., can solve the problems of affecting the safety and reliability of the boiler, twisting and deformation, and large deformation of connecting pipes, so as to enhance rigidity and ensure No distortion and deformation, and the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

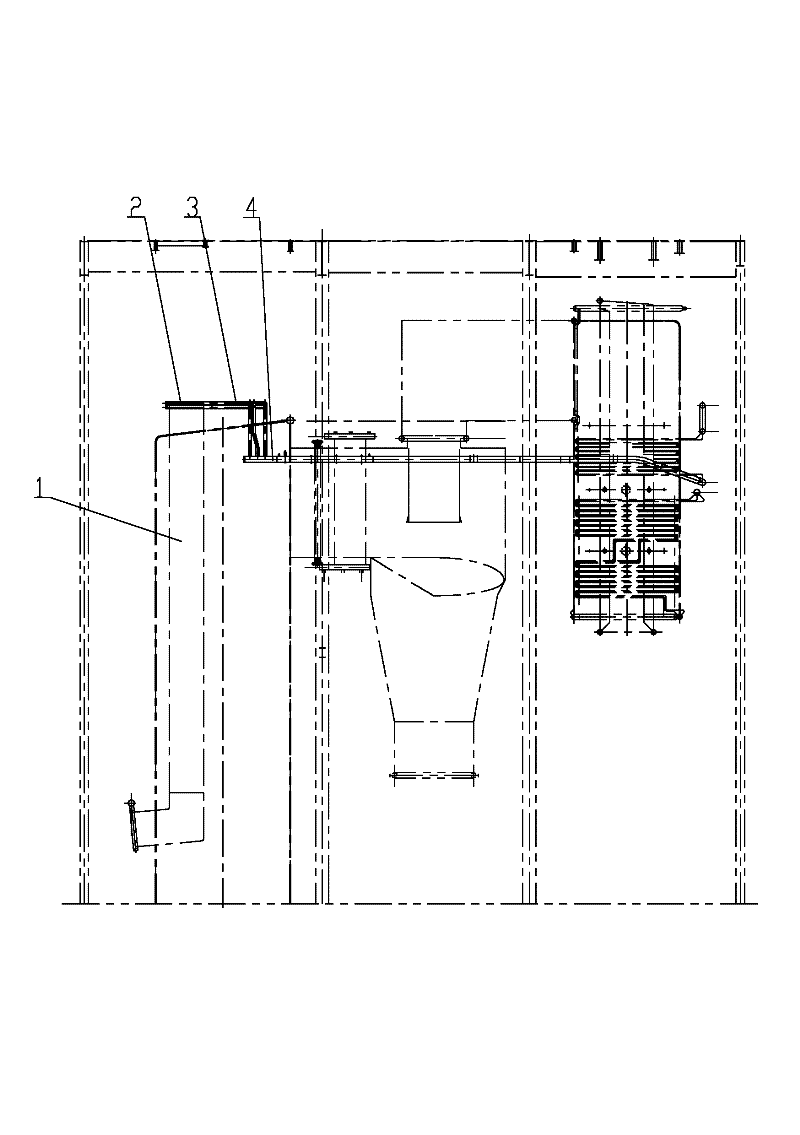

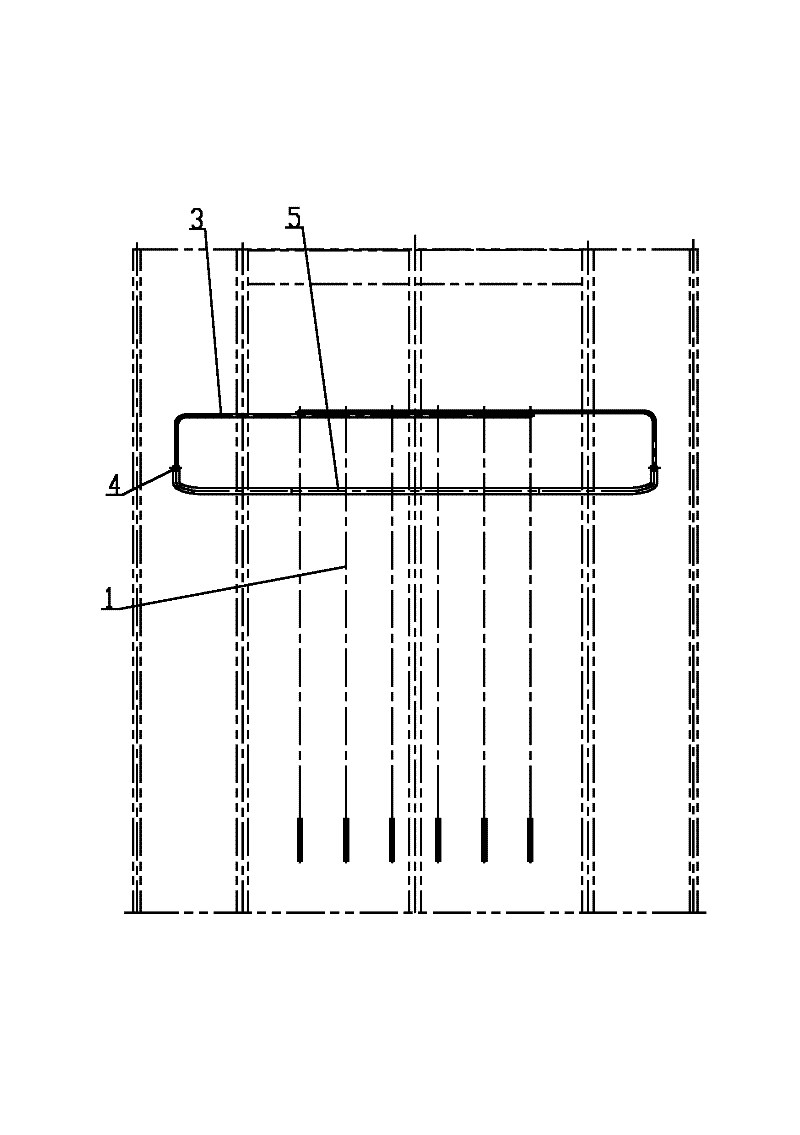

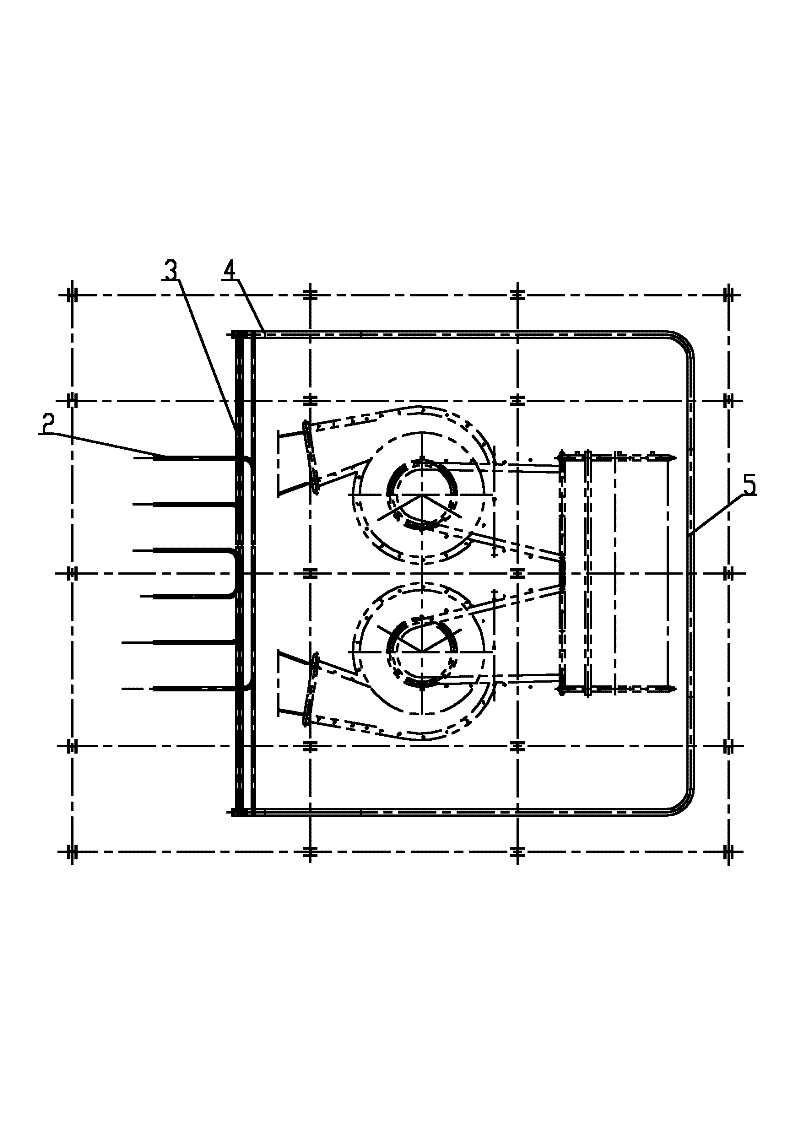

[0012] See Figure 4 , Figure 5 , Figure 6 , which includes panel superheater 1, panel superheater outlet header 2, connecting pipeline 3, summary pipeline, high temperature superheater inlet header 5, the summary pipeline is specifically a summary header 4, panel superheater outlet header 2 is arranged above collecting header 4, panel superheater outlet header 2 is connected to collecting header 4 through vertical connecting pipe 6, collecting header 4 is connected to high temperature superheater inlet header 5 through connecting pipe 3, and collecting header 4 The two ends far away from the vertical connecting pipe 6 are fitted with a limiting device 7, and one end of the limiting device 7 is tightly connected to the upper header 8 on the water-cooled wall of the side wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com