Air intake pressure stabilizing device of sequential supercharged diesel engine and control method thereof

A stable control method and sequential supercharging technology, applied in electrical control, engine control, fuel injection control, etc., can solve problems such as unstable operation, reduced exhaust gas flow rate of the basic turbocharger, and speed fluctuations, so as to improve the overall quality, The smooth effect of successive booster switching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

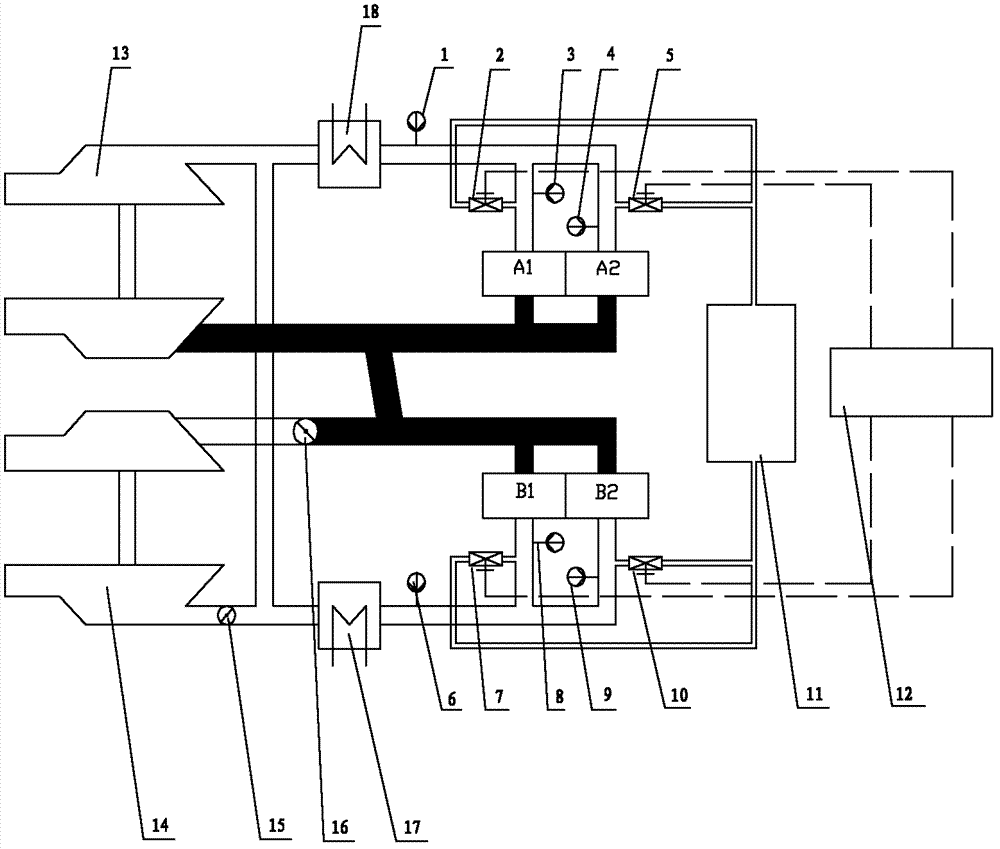

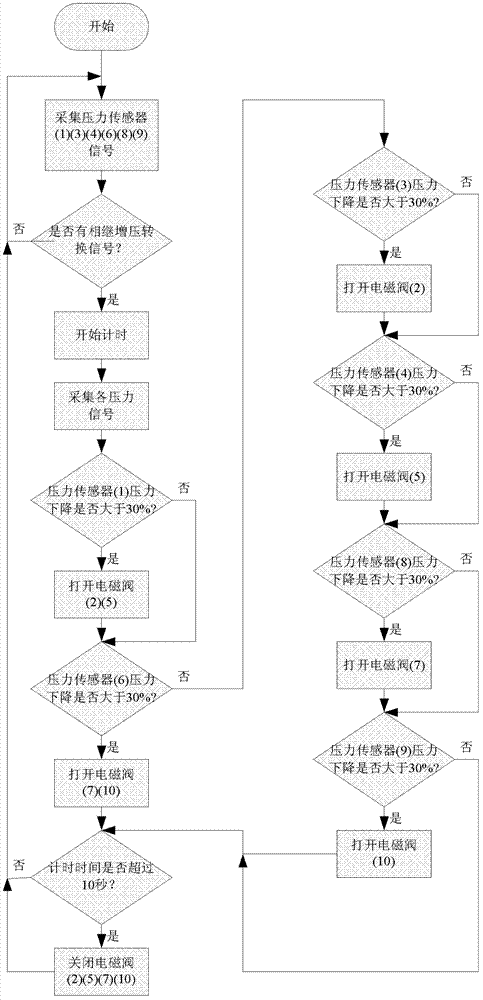

[0020] combine Figure 1~2 , the air intake pressure stabilizing device for successive supercharged diesel engines of the present invention, the turbocharger is connected with the cylinder of the diesel engine through a pipeline, the intercooler is installed on the pipeline connecting the compressor of the turbocharger with the cylinder of the diesel engine, the compressed air source 11 is connected with each The intake manifold of each diesel engine cylinder is connected, the outlet of the intercooler and the intake manifold of the diesel engine cylinder are equipped with pressure sensors, the intake manifold of the diesel engine cylinder is also equipped with a solenoid valve, and the intake pressure controller 12 is connected with the pressure sensor and the solenoid valve. There are two turbochargers, two intercoolers, intercooler 17 and intercooler 18, four d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com