Novel full-automatic pneumatic chuck for mouse hole

A hole pneumatic card, fully automatic technology, applied in drilling equipment, earthwork drilling, drill pipe and other directions, can solve the problems of potential safety hazards, wear and tear of mouse holes, affecting the service life, etc., to achieve compact structure and ensure safety. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

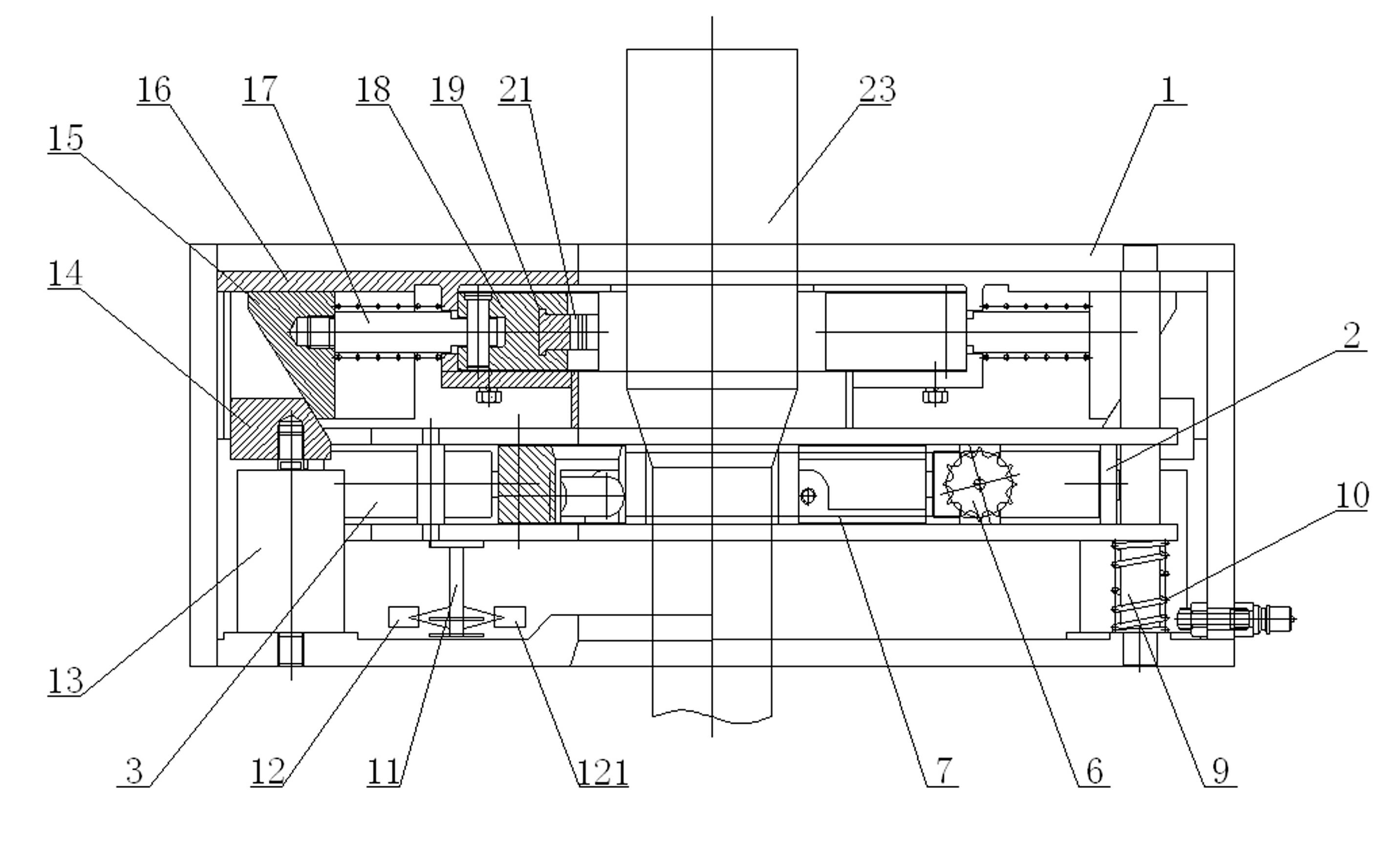

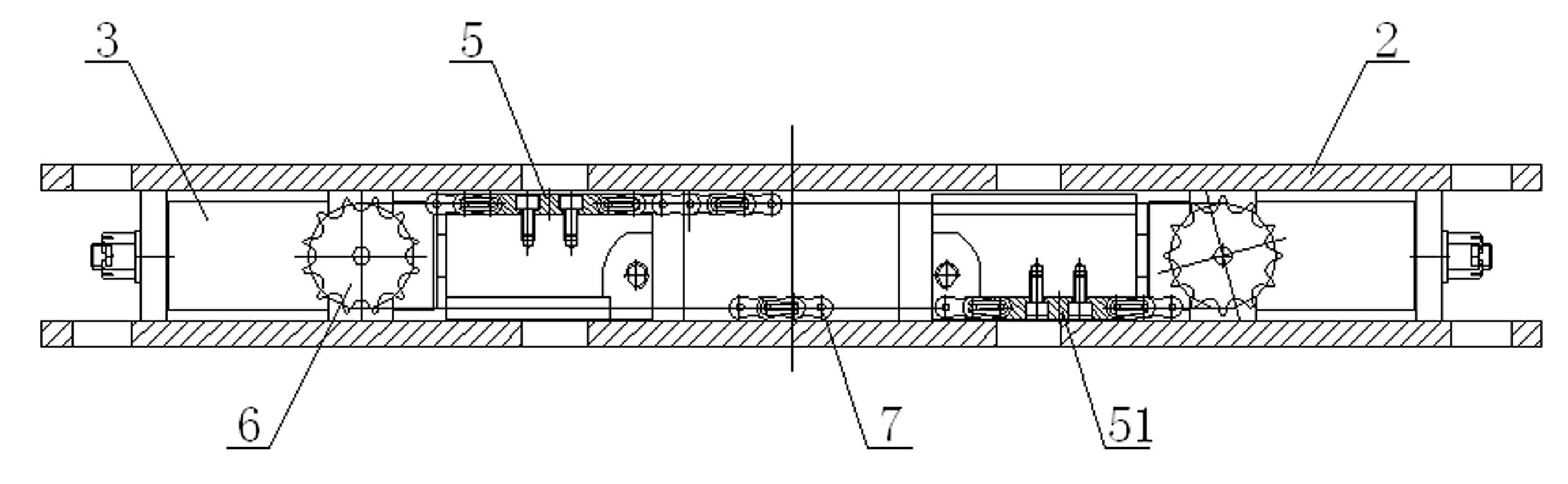

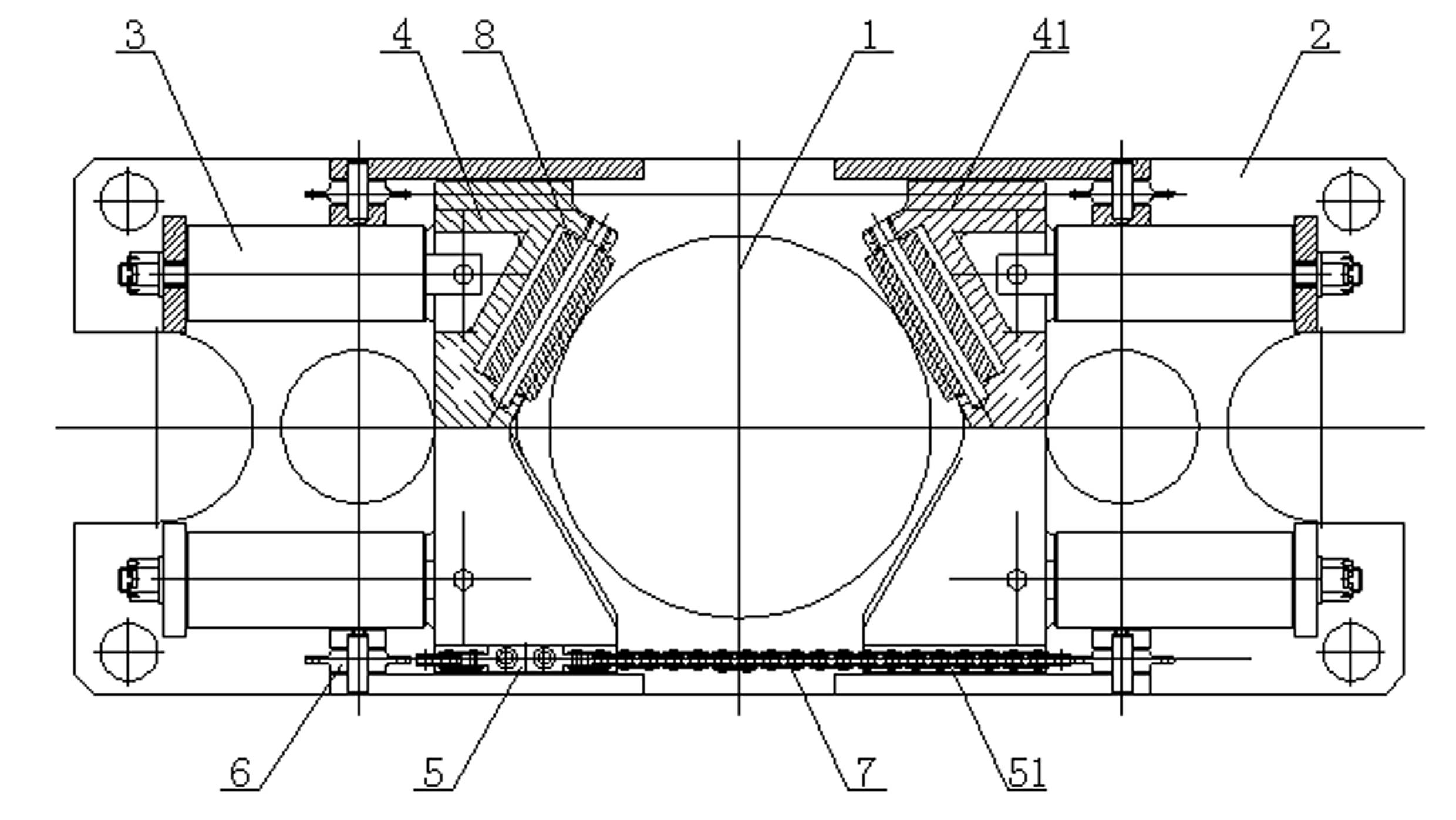

[0020] The present invention will be further described below in conjunction with accompanying drawing.

[0021] Figure 1-5 As shown, the new fully automatic mouse hole pneumatic chuck includes a box body 1, a righting box body 2, a righting cylinder 3, a left righting block 4, a right righting block 41, an upper connecting block 5, a lower connecting block 51, a sprocket 6, Chain 7, roller 8, guide post 9, guide post spring 10, shift fork 11, first reversing valve 12, second reversing valve 121, clamping cylinder 13, top block 14, slider 15, slide rail 16 , Push rod 17, pliers head 18, back-moving spring 20, dental plate 21 and reversing switch 22. The righting box 2 is installed on the four guide pillars 9 in the box body 1, and the bottom of the righting box 2 is supported on the four guide pillars by the guide post spring 10 sleeved on the guide pillars 9 in a state of floating up and down. Cylinder 3 is symmetrically installed on the four corners of the righting box 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com